How to Find a Reliable PCB Board Maker

By:Admin

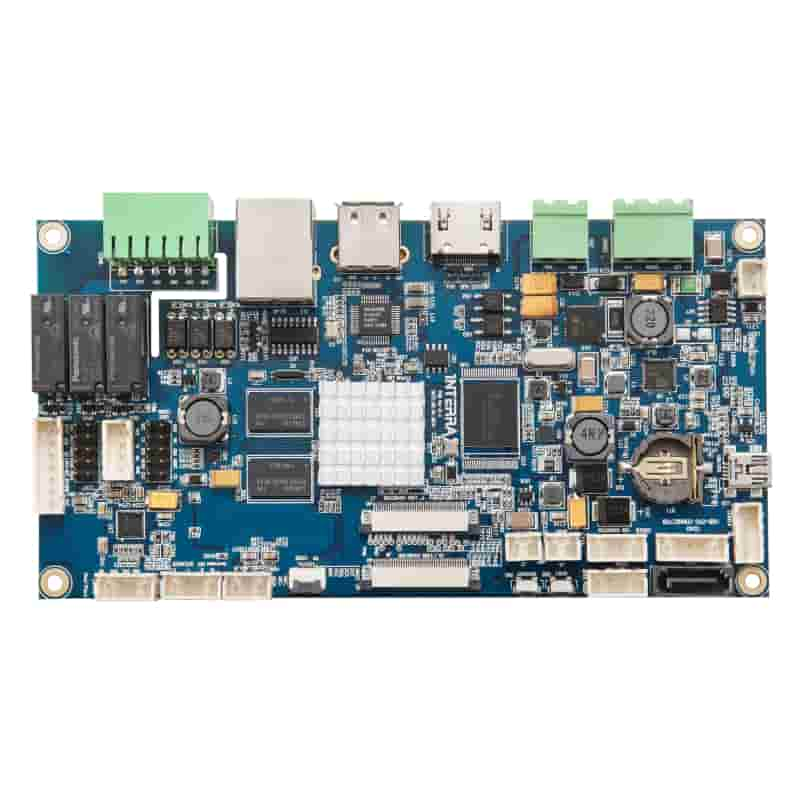

Established in [year], Pcb Board Maker has built a strong reputation for delivering top-notch PCBs that meet the rigorous demands of various industries, including telecommunications, automotive, aerospace, medical, and consumer electronics. The company's commitment to quality, precision, and technological advancement has propelled them to the forefront of the PCB manufacturing industry.

One of the key strengths of Pcb Board Maker lies in their state-of-the-art manufacturing facilities, equipped with cutting-edge machinery and advanced production techniques. This enables the company to produce PCBs with high precision and accuracy, meeting the most stringent quality standards. Additionally, Pcb Board Maker has a team of skilled engineers and technicians who are dedicated to ensuring that every PCB meets the exact specifications and requirements of their clients.

In response to the ever-evolving needs of the market, Pcb Board Maker has introduced a new line of advanced PCBs that boast improved performance, reliability, and functionality. These new PCBs incorporate the latest technological developments, such as advanced materials, intricate designs, and enhanced thermal management, to address the growing demands of modern electronic applications.

Furthermore, Pcb Board Maker has invested heavily in research and development to stay ahead of the curve in PCB technology. The company's R&D team continuously explores new materials, processes, and technologies to enhance the performance and capabilities of their PCBs. This proactive approach to innovation enables Pcb Board Maker to offer cutting-edge solutions that empower their clients to stay competitive in their respective markets.

In addition to their technical prowess, Pcb Board Maker prides itself on providing exceptional customer service and support. The company understands the importance of clear communication, prompt response, and reliable delivery in the PCB manufacturing process. As such, they have implemented robust customer service protocols to ensure that clients receive the assistance and guidance they need throughout the entire project lifecycle.

With their new line of advanced PCBs, Pcb Board Maker is poised to meet the growing demand for high-performance electronic components in a wide range of industries. The company's unwavering dedication to quality, innovation, and customer satisfaction sets them apart as a trusted partner for businesses seeking reliable PCB solutions.

As part of their commitment to excellence, Pcb Board Maker remains focused on staying abreast of industry trends, technological advancements, and customer feedback. By continuously refining their products and processes, the company is well-positioned to meet the evolving needs of the market and exceed the expectations of their clients.

In conclusion, Pcb Board Maker continues to make significant strides in the PCB manufacturing industry with the introduction of their latest line of advanced PCBs. Through a combination of cutting-edge technology, relentless innovation, and unparalleled customer support, the company has established itself as a premier provider of high-quality PCB solutions for businesses around the world. As the demand for reliable and efficient electronic components continues to rise, Pcb Board Maker stands ready to meet the challenges of the future and deliver exceptional products that drive success for their clients.

Company News & Blog

How to Find a Reliable PCB Board Maker

Pcb Board Maker, a leading provider of high-quality printed circuit boards, has announced the introduction of their latest line of advanced PCBs. With a focus on innovation and customer satisfaction, Pcb Board Maker continues to solidify their position as a trusted partner for businesses in need of reliable and efficient PCB solutions.Established in [year], Pcb Board Maker has built a strong reputation for delivering top-notch PCBs that meet the rigorous demands of various industries, including telecommunications, automotive, aerospace, medical, and consumer electronics. The company's commitment to quality, precision, and technological advancement has propelled them to the forefront of the PCB manufacturing industry.One of the key strengths of Pcb Board Maker lies in their state-of-the-art manufacturing facilities, equipped with cutting-edge machinery and advanced production techniques. This enables the company to produce PCBs with high precision and accuracy, meeting the most stringent quality standards. Additionally, Pcb Board Maker has a team of skilled engineers and technicians who are dedicated to ensuring that every PCB meets the exact specifications and requirements of their clients.In response to the ever-evolving needs of the market, Pcb Board Maker has introduced a new line of advanced PCBs that boast improved performance, reliability, and functionality. These new PCBs incorporate the latest technological developments, such as advanced materials, intricate designs, and enhanced thermal management, to address the growing demands of modern electronic applications.Furthermore, Pcb Board Maker has invested heavily in research and development to stay ahead of the curve in PCB technology. The company's R&D team continuously explores new materials, processes, and technologies to enhance the performance and capabilities of their PCBs. This proactive approach to innovation enables Pcb Board Maker to offer cutting-edge solutions that empower their clients to stay competitive in their respective markets.In addition to their technical prowess, Pcb Board Maker prides itself on providing exceptional customer service and support. The company understands the importance of clear communication, prompt response, and reliable delivery in the PCB manufacturing process. As such, they have implemented robust customer service protocols to ensure that clients receive the assistance and guidance they need throughout the entire project lifecycle.With their new line of advanced PCBs, Pcb Board Maker is poised to meet the growing demand for high-performance electronic components in a wide range of industries. The company's unwavering dedication to quality, innovation, and customer satisfaction sets them apart as a trusted partner for businesses seeking reliable PCB solutions.As part of their commitment to excellence, Pcb Board Maker remains focused on staying abreast of industry trends, technological advancements, and customer feedback. By continuously refining their products and processes, the company is well-positioned to meet the evolving needs of the market and exceed the expectations of their clients.In conclusion, Pcb Board Maker continues to make significant strides in the PCB manufacturing industry with the introduction of their latest line of advanced PCBs. Through a combination of cutting-edge technology, relentless innovation, and unparalleled customer support, the company has established itself as a premier provider of high-quality PCB solutions for businesses around the world. As the demand for reliable and efficient electronic components continues to rise, Pcb Board Maker stands ready to meet the challenges of the future and deliver exceptional products that drive success for their clients.

High-Quality Aluminium Board for PCB Manufacturing at Competitive Prices

Aluminium Board PCB, also known as Metal Core PCB, is a type of printed circuit board that is built on a base material made of aluminum. This type of PCB is ideal for applications that require high thermal conductivity and heat dissipation, such as LED lighting, power supplies, automotive electronics, and many others. One company at the forefront of producing high-quality Aluminium Board PCBs is {}. With years of experience and expertise in the PCB manufacturing industry, they have become a trusted source for companies seeking reliable and efficient PCB solutions. The company prides itself on its state-of-the-art manufacturing facilities and a team of skilled engineers and technicians who are dedicated to producing top-notch Aluminium Board PCBs. By utilizing advanced technology and stringent quality control measures, they ensure that each PCB meets the highest standards of performance and reliability.Their Aluminium Board PCBs are designed to efficiently dissipate heat away from critical components, allowing for improved performance and longevity of electronic devices. With a focus on precision and durability, their PCBs are able to withstand harsh operating conditions and demanding applications.In addition to their commitment to quality, the company also places a strong emphasis on customer satisfaction. They work closely with each client to understand their specific requirements and provide tailored solutions to meet their needs. By offering flexible production capabilities and a quick turnaround time, they are able to support clients in bringing their innovative products to market in a timely manner.Furthermore, the company is dedicated to environmental sustainability in their manufacturing processes. They adhere to strict environmental standards and regulations, and are constantly seeking ways to reduce their carbon footprint and minimize waste in their production operations.In line with their mission to be a leader in the PCB industry, the company is continuously investing in research and development to stay ahead of the curve and offer cutting-edge solutions to their customers. By staying abreast of the latest technological advancements, they are able to adapt to the evolving needs of the industry and provide innovative Aluminium Board PCBs that are at the forefront of performance and reliability.As the demand for Aluminium Board PCBs continues to grow in various industries, companies like {} are playing a crucial role in meeting this demand with high-quality, efficient, and reliable solutions. Their dedication to excellence, customer satisfaction, and environmental responsibility positions them as a trusted partner for businesses seeking top-tier Aluminium Board PCBs.In conclusion, the use of Aluminium Board PCBs has become increasingly prevalent in a wide range of electronic applications, and the need for reliable and high-quality PCB solutions has never been greater. With their commitment to excellence and innovation, {} is well-positioned to continue meeting the needs of the industry and supporting businesses in achieving their electronic design goals.

Benefits of Installing a High-Quality Air Conditioning PCB Board

Universal AC PCB Board: The Future of Air Conditioning SystemsAir conditioning has become an essential part of modern living, making it one of the six highest contributors to global warming. Currently, research suggests that approximately 90% of US citizens have an air conditioning unit in their homes. However, air conditioning units consume a lot of energy, which generates greenhouse gases that adversely affect our environment. The pressing need to develop greener air conditioning systems has led to the development of the Universal AC PCB Board.The Universal AC PCB Board is a state-of-the-art technology designed to enhance the energy efficiency of air conditioning systems. The board is an energy-saving device installed in an air conditioning unit. It regulates the AC system, ensuring that it consumes the least amount of energy possible while still providing top-notch cooling performance.One of the key benefits of the Universal AC PCB board is its flexible design, which allows it to fit into most kinds of air conditioning systems. This means that homeowners can access the energy-saving benefits of the Universal AC PCB board without having to replace their existing air conditioning units. The flexibility of this product extends to HVAC professionals who can integrate the Universal AC PCB Board into a wide variety of systems without requiring specialized knowledge or equipment. The Universal AC PCB board comprises advanced algorithms and embedded programming that ensure optimized performance. The algorithms continuously monitor and optimize the air conditioner's temperature regulation, smartly tuning the system to consume the least possible amount of energy. This eco-friendly feature helps reduce energy consumption and associated greenhouse gas emissions that are harmful to the environment.It is imperative that global warming concerns accelerate the need for eco-friendly devices such as the Universal AC PCB board. Government policies and programs that support greener air conditioning systems also increase the demand for these devices. With the increased demand, there is no doubt that the Universal AC PCB board is shaping the future of air conditioning systems.The Universal AC PCB Board is manufactured by a company that has been at the forefront of designing and developing cutting-edge technology for decades. The company specializes in the research, development, production, and sales of the Universal AC PCB board and related fields.The company prides itself on its research activities, which focus on cutting-edge technological advances that improve the efficiency and effectiveness of air conditioning systems. It has a seasoned team of experienced professionals, who combine their technical knowledge and problem-solving skills to deliver state-of-the-art solutions to clients globally.As a pioneer in the field of air conditioning, the company strives to ensure that its products comply with contemporary regulations and standards. The company is committed to a strict quality control process to ensure that every Universal AC PCB board produced meets the highest standards of quality and reliability.In conclusion, as eco-friendly devices with flexible and optimized designs, the Universal AC PCB board is a game-changer in the air conditioning industry. Their energy-saving capabilities and capacity to work across multiple types of air conditioning systems make the devices an essential tool for homeowners and HVAC professionals alike. Combining their pioneering technologies with experienced professionals, the future of air conditioning will undoubtedly be shaped by more products like the Universal AC PCB Board.

Fast and Efficient PCBA Services for Your Electronic Needs

Quick Turn PCBA is a leading provider of high-quality printed circuit board assembly (PCBA) services. The company offers a wide range of manufacturing capabilities, including surface mount technology, through-hole assembly, and mixed technology assembly. With a strong focus on quick turnarounds and superior quality, Quick Turn PCBA has become a trusted partner for numerous industries, including aerospace, automotive, medical, and telecommunications.Quick Turn PCBA has distinguished itself in the industry by prioritizing customer satisfaction and delivering exceptional results in a timely manner. The company's state-of-the-art facilities are equipped with the latest technology and machinery, ensuring precise and efficient assembly processes. With a team of highly skilled engineers and technicians, Quick Turn PCBA is capable of handling complex projects with ease and accuracy.In addition to its manufacturing capabilities, Quick Turn PCBA also offers comprehensive design and engineering support. The company works closely with its clients to optimize their designs for manufacturability, ensuring that the final product meets all specifications and requirements. This collaborative approach has earned Quick Turn PCBA a reputation for delivering cost-effective solutions without compromising on quality.One of the key factors that sets Quick Turn PCBA apart from its competitors is its commitment to rapid prototyping and quick turnaround times. The company understands the importance of speed to market in today's fast-paced industries, and has developed streamlined processes to minimize lead times without sacrificing quality. Quick Turn PCBA's ability to quickly bring new products to market gives its clients a competitive edge and helps them capitalize on emerging opportunities.Quick Turn PCBA's dedication to excellence and customer satisfaction has resulted in numerous accolades and certifications. The company is ISO 9001 certified, demonstrating its commitment to quality management and continuous improvement. Quick Turn PCBA also adheres to strict industry standards and regulations, ensuring that its products meet the highest levels of reliability and performance.With a strong track record of success and a growing list of satisfied clients, Quick Turn PCBA is poised for continued growth and expansion. The company is constantly investing in new technologies and process improvements to further enhance its capabilities and maintain its competitive edge. Quick Turn PCBA's unwavering focus on customer needs and satisfaction has solidified its position as a trusted partner for all PCBA requirements.As the demand for high-quality printed circuit board assembly continues to grow, Quick Turn PCBA remains at the forefront of the industry. The company's commitment to excellence, rapid prototyping, and quick turnarounds sets it apart as a reliable and innovative PCBA provider. With its cutting-edge technology, skilled team, and customer-centric approach, Quick Turn PCBA is well-positioned to meet the evolving needs of diverse industries and drive the success of its clients.

Population of PCBs in the Environment Continues to Increase, Study Finds

The PCB population is on the rise, with the demand for efficient and reliable printed circuit boards (PCBs) increasing across various industries. As the global market for electronic devices continues to expand, the need for high-quality PCBs has become more critical than ever.[Company] is a leading manufacturer of PCBs that has been catering to the growing demand for cutting-edge electronic components. With a team of skilled engineers and state-of-the-art technology, the company has established itself as a trusted name in the industry.The PCB population refers to the number of PCBs being produced and used in different applications, ranging from consumer electronics to industrial equipment. As technology continues to advance, the demand for smaller, more durable, and versatile PCBs has increased significantly.[Company] has been at the forefront of this trend, offering a wide range of PCB solutions that cater to the diverse needs of its customers. From single-layer to multi-layer PCBs, the company has the capabilities to deliver high-quality products that meet the stringent requirements of modern electronic devices.One of the key factors driving the growth of the PCB population is the increasing adoption of Internet of Things (IoT) devices. With IoT devices becoming more prevalent in homes, businesses, and industrial settings, the demand for PCBs that can support these applications has surged.[Company] has been quick to adapt to this trend, developing PCBs that are specifically designed to meet the unique requirements of IoT devices. By leveraging its expertise in electronic engineering and manufacturing, the company has positioned itself as a preferred supplier for IoT PCBs.In addition to IoT devices, the automotive industry has also been a significant driver of the PCB population growth. With the increasing integration of electronic systems in vehicles, the demand for high-performance PCBs has soared. [Company], with its focus on producing reliable and durable PCBs, has been able to capitalize on this trend, supplying PCBs for automotive applications that require superior quality and performance.The medical industry is another sector that has contributed to the growth of the PCB population. With the advancement of medical technology, the need for PCBs that can support sophisticated medical devices has increased. [Company], with its commitment to producing PCBs that meet the highest standards of quality and reliability, has been able to establish itself as a trusted partner for medical equipment manufacturers.As the PCB population continues to grow, [Company] remains committed to meeting the evolving needs of its customers. With a focus on innovation and quality, the company is continuously investing in research and development to develop new PCB solutions that can address the emerging requirements of the market.With a diverse portfolio of PCB products and a strong commitment to customer satisfaction, [Company] is well-positioned to capitalize on the growing PCB population. As the demand for electronic devices continues to expand, the company remains focused on delivering high-quality PCBs that can support the next generation of technological advancements.

Complete guide to Pcb Semi Flex: everything you need to know

PCB Semi Flex, a leading provider of innovative flexible printed circuit board solutions, has recently introduced a new semi-flexible PCB technology that is set to revolutionize the electronics industry. The company, with its state-of-the-art manufacturing facility and a team of experienced engineers, has been at the forefront of developing cutting-edge PCB solutions for various applications.The new semi-flex PCB technology is designed to address the increasing demand for high-performance, space-saving, and reliable PCB solutions. With the increasing trend towards miniaturization of electronic devices, the need for flexible and semi-flexible PCBs has become more pronounced. PCB Semi Flex has recognized this need and has developed a technology that offers the best of both worlds - the flexibility of a flexible PCB and the stability of a rigid PCB.One of the key features of the new technology is its ability to bend and flex without compromising the electrical and mechanical performance of the PCB. This is achieved through innovative design and materials that allow the PCB to bend and flex while maintaining signal integrity and reliability. This makes the technology ideal for applications where space is limited, and the PCB needs to conform to a specific shape or form factor.Furthermore, the semi-flex PCB technology offers excellent thermal performance, making it suitable for applications where heat dissipation is a concern. The technology also provides high-density interconnects, allowing for more complex and compact designs without sacrificing performance.In addition to its technical capabilities, PCB Semi Flex is also committed to providing environmentally friendly solutions. The company uses advanced manufacturing processes that minimize waste and energy consumption, ensuring that its products have minimal impact on the environment.With its new semi-flex PCB technology, PCB Semi Flex aims to cater to a wide range of industries, including automotive, aerospace, consumer electronics, medical devices, and more. The technology is versatile and can be customized to meet the specific requirements of different applications, making it a viable solution for various electronic design needs."We are excited to introduce our new semi-flex PCB technology to the market," said the CEO of PCB Semi Flex. "We believe that this technology will open up new possibilities for electronic design and provide our customers with innovative solutions that meet their evolving needs."As a company, PCB Semi Flex has a strong track record of delivering high-quality PCB solutions to its customers. The company's commitment to innovation, technical expertise, and customer satisfaction has made it a trusted partner for numerous businesses seeking reliable PCB solutions.The introduction of the new semi-flex PCB technology further solidifies PCB Semi Flex's position as a leader in the industry. The company's dedication to pushing the boundaries of PCB technology and its ability to adapt to the changing needs of the market will drive its continued success.In conclusion, PCB Semi Flex's new semi-flex PCB technology is set to redefine the way electronic devices are designed and manufactured. With its unique combination of flexibility, reliability, and performance, the technology offers a compelling solution for various industries. As PCB Semi Flex continues to push the boundaries of PCB technology, it is poised to remain a key player in the electronics industry for years to come.

Pcb Cable Assembly: Streamlining Connections for Improved Efficiency

PCB Cable Assembly Company Introduces State-of-the-Art Electronic Manufacturing ServicesPCB Cable Assembly is proud to announce its comprehensive and state-of-the-art electronic manufacturing services that cater to the ever-evolving needs of the electronics industry. Whatever your PCB manufacturing needs are, PCB Cable Assembly has the expertise and abilities to provide complete solutions from prototype to end-user products.Our company specializes in providing electronic manufacturing services such as complete PCB design, PCB assembly, cable assembly, custom cable assembly, and electromechanical assembly. We have a track record of delivering superior products that meet standard industry regulations and requirements.Our facility is equipped with the latest in manufacturing technology, such as automated and semi-automated assembly systems. This technology ensures high levels of precision, superior quality, and fast turnaround times. Our team of engineers, designers, technicians, and customer service professionals have years of experience in the industry to provide unrivaled expertise to our clients.With our rapid prototyping service, customers can have a working model of their product within a few days. This service not only saves time, but it also allows customers to test their products and make improvements before launching them in the market. PCB Cable Assembly also specializes in manufacturing small to mid-sized batches to accommodate the needs of businesses that need a small number of products.At PCB Cable Assembly, we prioritize customer satisfaction with providing high-quality products, fast turnaround times, and competitive pricing. We manage the end-to-end process of producing your product. Our services include product design, component sourcing, circuit board fabrication, PCB assembly, and final assembly.Another unique service that we offer is electromechanical assembly. We assemble sub-assemblies and finished products that combine the electronic and mechanical components. In addition, we offer wire harness and cable assemblies that are made to order and customized to our client's needs. We use a wide variety of connectors, terminals, and cables to ensure optimal compatibility with the client's products.We take pride in providing high-quality services at competitive prices. Our clients can be assured of the consistency and quality of the products we produce with our high-tech manufacturing equipment operated by skilled professionals. Furthermore, we have earned a reputation for timely delivery, excellent customer service, and value for money, which sets us apart from our competitors.In conclusion, PCB Cable Assembly has made an indelible mark in the electronics industry by providing comprehensive electronic manufacturing services that help businesses bring their product ideas to life. Our state-of-the-art technology, skilled workforce, and commitment to customer satisfaction have won the hearts of our clients, and we seek to continuously improve and innovate to keep up with the evolving technological landscape. Contact us today to see how we can bring your electronic product ideas to life.

Durable and Reliable Fr4 PCBs for Your Electronic Projects

The use of Fr4 PCBs in electronic devices has become increasingly popular due to their exceptional quality and performance. Fr4 PCBs are known for their high thermal resistance and durability, making them the preferred choice for a wide range of applications, from consumer electronics to industrial equipment.One company that has established itself as a leading manufacturer of Fr4 PCBs is {}. With over 20 years of experience in the industry, {} has earned a reputation for delivering top-notch Fr4 PCBs that meet the stringent quality standards of its clients.{} specializes in the production of Fr4 PCBs for a variety of industries, including automotive, telecommunications, medical devices, and aerospace. The company's state-of-the-art manufacturing facility is equipped with the latest technology and machinery, allowing {} to produce Fr4 PCBs with precision and efficiency.One of the key advantages of {}'s Fr4 PCBs is their exceptional thermal performance. The company uses high-quality materials and advanced manufacturing techniques to ensure that its Fr4 PCBs can withstand high temperatures and operate reliably in challenging environments. This makes {}'s Fr4 PCBs an ideal choice for applications that require reliable performance under extreme conditions.In addition to thermal resistance, {}'s Fr4 PCBs are also known for their excellent electrical performance. The company's skilled engineers and technicians work closely with clients to develop custom Fr4 PCBs that meet their specific electrical requirements. Whether it's high-speed data transmission or precise signal control, {} can design and manufacture Fr4 PCBs that deliver exceptional electrical performance.Quality is a top priority at {}, and the company has implemented rigorous quality control processes to ensure that its Fr4 PCBs meet the highest standards. From raw material inspection to final product testing, {} follows strict quality guidelines at every stage of the manufacturing process. This commitment to quality has earned {} the trust and confidence of its clients, who rely on the company to deliver Fr4 PCBs that meet their exact specifications.As the demand for high-performance electronic devices continues to grow, {} remains at the forefront of Fr4 PCB manufacturing. The company's dedication to innovation and excellence has enabled it to stay ahead of the competition and provide its clients with Fr4 PCBs that offer unmatched performance and reliability.With a strong focus on customer satisfaction, {} works closely with its clients to understand their unique needs and provide them with Fr4 PCB solutions that exceed their expectations. Whether it's a small prototype run or a large-scale production order, {} is committed to delivering Fr4 PCBs that meet the highest quality standards and performance requirements.In conclusion, the use of Fr4 PCBs has become increasingly prevalent in electronic devices, and {} has established itself as a leading manufacturer of high-quality Fr4 PCBs. With its advanced manufacturing capabilities, commitment to quality, and focus on customer satisfaction, {} is well-positioned to meet the growing demand for top-notch Fr4 PCB solutions in a wide range of industries.

How to Choose the Best PC Board Assembly for Your Needs

Pc Board Assembly Company, a leader in electronics manufacturing and assembly, has recently made significant advancements in their production process to meet the increasing demand for high-quality electronic components. The company, with its state-of-the-art facilities and top-notch team of engineers and technicians, has been providing superior pc board assembly services to clients across various industries. With a focus on technological innovation and customer satisfaction, Pc Board Assembly Company has established itself as a trusted partner for businesses seeking reliable electronic manufacturing solutions.Established in (Year), Pc Board Assembly Company has continuously upgraded its manufacturing capabilities to keep pace with the ever-evolving electronics industry. The company specializes in the production of rigid, flexible, and rigid-flex pc boards, utilizing advanced techniques such as surface mount technology (SMT) and through-hole assembly to accommodate the diverse needs of their clients. With a comprehensive range of services including design, prototyping, and full-scale production, Pc Board Assembly Company is equipped to handle projects of any size and complexity.Moreover, the company takes pride in its commitment to quality and precision. Every pc board assembly undergoes rigorous testing and inspection, ensuring that it meets the highest standards of performance and reliability. By adhering to strict quality control measures, Pc Board Assembly Company has gained a reputation for delivering flawless electronic components that exceed industry benchmarks.In light of the growing demand for advanced electronic devices, Pc Board Assembly Company has invested in cutting-edge technologies and equipment to enhance its manufacturing process. The company has recently integrated automated assembly systems into its operations, allowing for greater efficiency and productivity while maintaining the highest level of accuracy. This strategic upgrade has significantly reduced production lead times and enabled Pc Board Assembly Company to meet the escalating demands of its clientele promptly.Furthermore, Pc Board Assembly Company recognizes the importance of environmental responsibility in its manufacturing practices. The company is committed to sustainable production methods and has implemented eco-friendly initiatives to minimize its carbon footprint. By utilizing energy-efficient machinery and adhering to environmentally conscious processes, Pc Board Assembly Company is dedicated to promoting a greener and cleaner manufacturing environment.In addition to its technical capabilities, Pc Board Assembly Company places a strong emphasis on client collaboration and satisfaction. The company's team of skilled engineers and project managers work closely with customers to understand their unique requirements and provide tailored solutions that align with their specific goals. Whether it's a prototype development or a large-scale production run, Pc Board Assembly Company is dedicated to delivering personalized service and exceptional results.As the demand for high-quality electronic components continues to rise, Pc Board Assembly Company remains at the forefront of innovation, driving the industry forward with its unwavering commitment to excellence. With its advanced manufacturing capabilities, stringent quality control measures, and customer-centric approach, the company is well-positioned to meet the evolving needs of the electronics market and maintain its status as a premier provider of pc board assembly services.In conclusion, Pc Board Assembly Company's dedication to technological advancement, quality assurance, and customer satisfaction sets it apart as a leading force in the electronics manufacturing industry. With a focus on innovation and precision, the company continues to raise the bar for pc board assembly, delivering exceptional results that exceed expectations. As the industry continues to evolve, Pc Board Assembly Company remains steadfast in its commitment to providing cutting-edge solutions and superior electronic components for businesses worldwide.

How to Get a Customized PCBA for Your Needs

Customized PCBA: Empowering Innovation and Efficiency in Electronics ManufacturingIn today's fast-paced and constantly evolving technological landscape, innovation and efficiency are crucial for success in the electronics manufacturing industry. As demand for cutting-edge electronic devices continues to grow, companies are constantly searching for new ways to improve their products and processes. One company at the forefront of this movement is {Company X}, a leading provider of customized PCBA solutions.{Company X} specializes in providing customized PCBA (Printed Circuit Board Assembly) services to a wide range of industries, including consumer electronics, automotive, medical devices, telecommunications, and industrial equipment. With state-of-the-art facilities and a team of experienced engineers, {Company X} has earned a reputation for delivering high-quality, cost-effective, and reliable PCBA solutions to its clients.One of the key advantages of choosing {Company X} for PCBA services is its ability to tailor its solutions to meet the specific needs of each client. Whether a company requires a small batch of prototype PCBAs for testing and validation or a large-scale production run, {Company X} can accommodate their requirements with personalized solutions. This flexibility allows companies to bring their innovative ideas to life without compromising on the quality and performance of their electronic products.Furthermore, {Company X} is committed to staying at the forefront of technological advancements in the electronics manufacturing industry. The company continuously invests in research and development to improve its manufacturing processes, enhance product quality, and reduce lead times. By leveraging the latest technologies and industry best practices, {Company X} helps its clients stay ahead of the competition and meet the ever-changing demands of the market.In addition to its technical expertise, {Company X} also prides itself on its dedication to customer satisfaction. The company works closely with its clients throughout the entire PCBA process, from design and prototyping to production and testing. This collaborative approach ensures that the final product meets the client's exact specifications and exceeds their expectations.With a focus on quality, reliability, and customer service, {Company X} has become a trusted partner for numerous companies looking to outsource their PCBA needs. By choosing {Company X} as their PCBA provider, companies can streamline their production processes, reduce time to market, and ultimately, improve their bottom line.In conclusion, {Company X} is at the forefront of empowering innovation and efficiency in the electronics manufacturing industry through its customized PCBA solutions. With a commitment to quality, flexibility, and customer satisfaction, the company continues to help its clients bring their innovative electronic products to market. As technology continues to advance, {Company X} remains dedicated to staying ahead of the curve and providing cutting-edge PCBA solutions to meet the evolving needs of the industry.