Top 5 Tips for Successful PCB Assembly and Surface Mount Technology

By:Admin

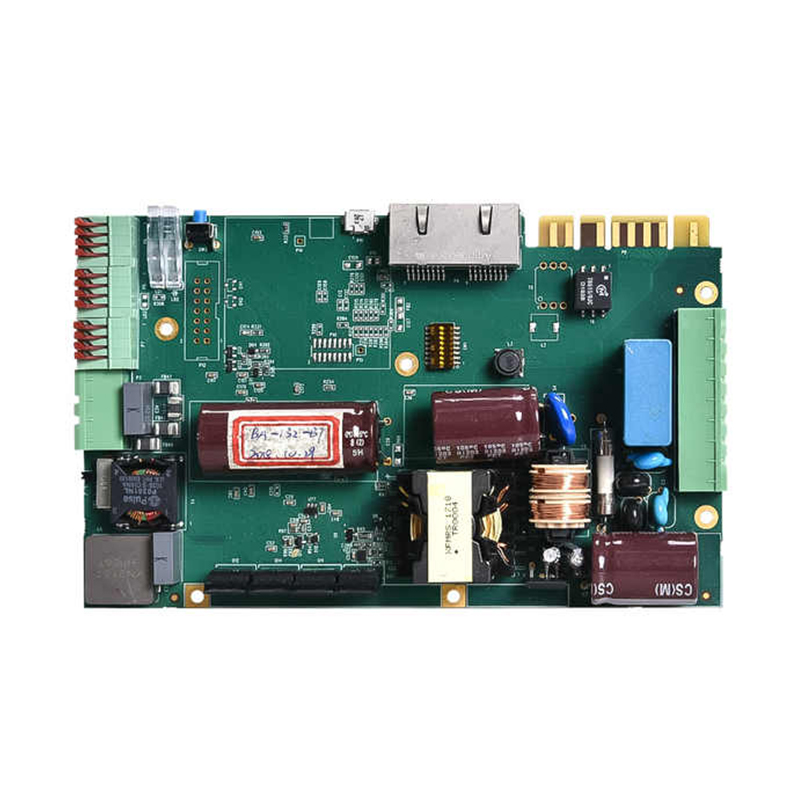

In the world of electronic manufacturing, [Company Name] is a renowned name, known for its expertise in PCBA Smt services. The company has a long-standing reputation for delivering high-quality, efficient, and cost-effective PCBA SMT solutions to its clients. With state-of-the-art facilities and a team of experienced professionals, [Company Name] has been at the forefront of the electronic manufacturing industry.

Recently, [Company Name] unveiled its latest advancements in PCBA Smt technology, showcasing its commitment to innovation and excellence in the field. The company has invested in cutting-edge equipment and technology to enhance its PCBA SMT capabilities, allowing for faster production, improved efficiency, and the ability to handle complex assembly requirements.

One of the key highlights of [Company Name]'s PCBA SMT services is its capability to handle a wide range of component sizes and types, from micro-sized chips to larger components. This flexibility enables the company to cater to the diverse needs of its clients, whether they require compact and sleek designs or more robust and intricate electronic assemblies.

Additionally, [Company Name] has integrated advanced quality control measures into its PCBA SMT processes, ensuring that every assembled circuit board meets the highest industry standards for reliability and performance. This commitment to quality is a testament to the company's dedication to delivering superior products to its clients.

Furthermore, [Company Name] has a strong focus on environmental sustainability in its PCBA SMT operations. The company has implemented eco-friendly practices and processes to minimize waste, reduce energy consumption, and promote the responsible use of resources. By taking a proactive approach to sustainability, [Company Name] is not only contributing to a greener planet but also aligning with the growing demand for environmentally conscious manufacturing practices.

In addition to its technical expertise, [Company Name] prides itself on its customer-centric approach. The company works closely with its clients to understand their unique requirements and provide customized PCBA SMT solutions that meet their specific needs. By fostering collaborative partnerships and maintaining open lines of communication, [Company Name] ensures that it delivers value-added services that exceed its clients' expectations.

With its latest advancements in PCBA Smt technology, [Company Name] is well-positioned to meet the evolving demands of the electronic manufacturing industry. The company's dedication to innovation, quality, and customer satisfaction sets it apart as a leader in the field of PCBA SMT services.

As the electronic manufacturing landscape continues to evolve, [Company Name] remains committed to staying ahead of the curve and setting new standards for excellence in PCBA SMT. With its state-of-the-art capabilities, environmental responsibility, and customer-centric approach, [Company Name] is poised to drive the future of electronic manufacturing with its PCBA SMT solutions.

Company News & Blog

Exploring the Benefits and Applications of Aluminum-Based PCBs

Title: Aluminum Base PCB Gaining Popularity: Innovations Paving the Way for Enhanced Electronic PerformanceIntroduction:In the ever-evolving electronics industry, the demand for high-performance printed circuit boards (PCBs) has significantly increased. One such innovation making waves is the Aluminum Base PCB, designed to provide exceptional heat dissipation capabilities. This article highlights the growing popularity of Aluminum Base PCBs and delves into the key features that make them stand out from conventional PCBs.Paragraph 1:Aluminum Base PCBs have witnessed a surge in utilization across various industries due to their unmatched thermal management properties. They offer exceptional heat dissipation, making them ideal for high-power applications where temperature control is critical. The combination of high thermal conductivity of aluminum and the multilayer construct of the PCB allows for efficient heat transfer, leading to increased performance and reliability.Paragraph 2:The advantages of Aluminum Base PCBs extend beyond thermal management; they also offer enhanced mechanical strength and rigidity. The aluminum substrate provides stability to the overall structure, preventing warping and ensuring longevity, even in demanding operating conditions. These attributes make Aluminum Base PCBs a popular choice in sectors such as automotive, aerospace, LED lighting, and power electronics.Paragraph 3:One of the most significant advantages of Aluminum Base PCBs is their compatibility with Surface Mount Technology (SMT), which greatly simplifies the assembly process. The aluminum substrate serves as an excellent thermal conductor during soldering, facilitating quick and efficient temperature transfer, leading to improved solder joint formation. This compatibility enhances productivity, shortens production lead times, and reduces costs in manufacturing processes.Paragraph 4:Several companies have been at the forefront of Aluminum Base PCB innovation, catering to the growing market demand. While each company brings its unique expertise and technologies, one company that has stood out is {}. Recognized for its commitment to excellence, their Aluminum Base PCBs have made a significant impact across multiple industries. By combining the most advanced engineering techniques with top-notch materials, their PCBs deliver unmatched performance and reliability.Paragraph 5:As the demand for high-performance electronic devices continues to grow, the aluminum base PCB market is projected to witness significant expansion. The automotive industry, in particular, is one of the key sectors driving this growth. Due to the increasing electrification of vehicles, the need for efficient thermal management systems in electric and hybrid vehicles has become paramount. Aluminum Base PCBs offer a reliable solution, ensuring the optimal functioning of sensitive electronic components.Paragraph 6:Beyond automotive, industries such as telecommunications, renewable energy, and industrial automation are also increasingly adopting Aluminum Base PCB technology. From power converters and motor controls to communication infrastructure and solar inverters, the unique attributes of Aluminum Base PCBs ensure stable performance, longevity, and efficient heat dissipation.Conclusion:With their exceptional thermal management properties, mechanical strength, and compatibility with modern manufacturing processes, Aluminum Base PCBs have emerged as a game-changer in the electronics industry. The relentless pursuit of innovation and commitment to delivering superior quality by companies like {} have laid the foundation for enhanced electronic performance. As the demand for high-power applications and thermal management efficiency grows, Aluminum Base PCBs are set to revolutionize the industry, driving technological advancements and powering the devices of tomorrow.

Easily Connect Your Fingerprint Scanner to Your Computer with a USB Adapter

Fpc To Usb - A Solution to Your Connectivity WoesIn today's world, where technology has become an integral part of our lives, it is not surprising that there is a significant need for devices that facilitate connectivity. Whether it is for charging your phone, transferring files from one device to another, or simply syncing your data, having a reliable and efficient connection is crucial.This is where FPC to USB comes in. FPC stands for Flexible Printed Circuit, and it refers to a type of circuit board that is made from a thin and flexible material. With the introduction of FPC to USB, it is now possible to connect devices that were previously incompatible, and in turn, make life a lot easier for tech-savvy individuals.One company that has made significant strides in this area is (Brand Name). Established in 2014, it has quickly risen to become a leading manufacturer of flexible printed circuits and other related products. With its headquarters located in (Location), and an extensive network of distributors worldwide, (Brand Name) has become a trusted name in the electronics industry.Their FPC to USB solution, in particular, has received a lot of accolades from customers and industry experts alike. This product is designed to bridge the gap between devices that have different connectivity ports. For example, if you have a device that only has an FPC port, but you want to connect it to a USB device, you can use (Brand Name)'s FPC to USB converter to achieve this.The converter itself is small and compact, which makes it easy to carry around. It is made using high-quality materials, ensuring that it has excellent durability and longevity. This means that you can rely on it to work seamlessly, without any hiccups, for an extended period.One of the unique selling points of this product is its compatibility. The FPC to USB converter is designed to work with a wide range of devices, including phones, tablets, laptops, and other electronics. This versatility makes it an ideal solution for individuals who have multiple devices that require different connectivity options.Another significant advantage of the FPC to USB converter is its affordability. Given the high-quality materials used in its construction and its versatility, you might expect the product to come with a hefty price tag. However, (Brand Name) has managed to keep the cost of this product low, making it accessible to a wide range of customers.Overall, the FPC to USB converter from (Brand Name) is an excellent solution for individuals who need to connect devices with different connectivity ports. Its versatility, affordability, and high-quality construction make it a must-have for anyone who uses multiple devices. If you're tired of struggling with compatibility issues and connectivity woes, it's time to invest in (Brand Name)'s FPC to USB converter and enjoy seamless connectivity like never before.

Exploring the Advanced Features and Benefits of Multilayer FR4 PCBs

Title: Cutting-Edge FR4 Multilayer PCB Revolutionizes the Electronics IndustryIntroduction:In a constantly evolving electronics industry, technological advancements have become the driving force behind innovation and growth. Among the latest breakthroughs is the introduction of FR4 Multilayer PCB, bringing a new level of efficiency, reliability, and compactness to electronic devices. One pioneering company has been at the forefront of this groundbreaking technology, utilizing its staggering expertise to reshape various industries. With their revolutionary FR4 Multilayer PCB, they are effectively revolutionizing electronics manufacturing and driving the next wave of technological advancements.Company Background:With a rich history spanning several decades, the deemed company has established itself as a pioneer in the electronics industry. Harnessing their unparalleled experience and technological prowess, they have developed a diverse portfolio of cutting-edge solutions. Maintaining their commitment to innovation, the company has collaborated with industry leaders and research institutions, ensuring they remain on the forefront of technological advancements.FR4 Multilayer PCB: Redefining the NormsThe FR4 Multilayer PCB has redefined the standards of electronics manufacturing, offering a multitude of advantages over traditional PCBs. Designed with multiple layers of copper and insulating material, this ground-breaking technology enables the integration of complex functionalities and components in compact devices.1. Enhanced Performance:The FR4 Multilayer PCB significantly improves overall product performance. With its high-density design, it allows signals to travel shorter distances, thereby minimizing electrical interference and signal loss. This remarkable advancement ensures faster data transmission, greater signal integrity, and performance optimization, ultimately leading to enhanced efficiency.2. Compact and Lightweight:The compactness of FR4 Multilayer PCBs is a game-changer for electronics manufacturers. By integrating multiple layers into a single circuit board, the overall size and weight of devices are significantly reduced without sacrificing functionality or reliability. This breakthrough has opened the doors for smaller, sleeker electronic devices, offering enhanced portability and design flexibility.3. Improved Reliability:FR4 Multilayer PCBs provide unparalleled reliability, offering greater resistance to environmental factors, such as heat, moisture, and vibrations. This heightened durability ensures the longevity and stability of electronic devices, avoiding frequent repairs or replacements. Moreover, the enhanced reliability offered by FR4 Multilayer PCBs contributes to increased product lifespan, reducing overall costs for manufacturers and end-users alike.4. Design Flexibility:With FR4 Multilayer PCBs, manufacturers have newfound design flexibility. The multilayered structure allows for precise assembly of complex circuits, enabling the addition of various components and functionalities in a single board. This advantage permits electronics manufacturers to produce durable, high-performance devices tailored to meet the ever-evolving needs of consumers.Market Applications and Impact:The introduction of FR4 Multilayer PCBs has sparked immense interest across various industries:1. Consumer Electronics: The compactness and enhanced performance of FR4 Multilayer PCBs have revolutionized consumer electronics, allowing manufacturers to develop smaller, sleeker devices without compromising functionality.2. Automotive Industry: In the automotive sector, FR4 Multilayer PCBs' durability and reliability have dramatically improved safety features, control systems, and connectivity solutions, fostering the development of smart cars.3. Telecommunications: The unparalleled performance and reliability of FR4 Multilayer PCBs have significantly contributed to achieving faster data transmission speeds, supporting the growing demand for high-speed connectivity.4. Medical Devices: In the medical field, FR4 Multilayer PCBs offer exceptional precision and reliability, enabling the development of advanced medical imaging systems, patient monitoring devices, and implantable electronics.Conclusion:As the electronics industry continues to advance at an unprecedented pace, the introduction of FR4 Multilayer PCBs stands as a technological marvel. The pioneering company, revered for its unwavering commitment to innovation, has reshaped multiple industries with its cutting-edge FR4 Multilayer PCB technology. From consumer electronics to medical devices, this ground-breaking solution has enhanced performance, reliability, and design flexibility, setting new norms for the future of electronics manufacturing. With the continued evolution of FR4 Multilayer PCBs, the possibilities for technological advancements are boundless.

How to Design a PCBA for Optimal Functionality and Performance

PCBA Design Company Leads the Way in Innovative Circuit Board SolutionsIn today's fast-paced and technologically advanced world, the demand for high-quality and innovative circuit board solutions is constantly growing. As a result, companies like PCBA Design, a global leader in the industry, are continuously working to push the boundaries of what is possible in electronics manufacturing. With a focus on state-of-the-art technology and unparalleled expertise, PCBA Design is setting new standards for circuit board design and production.Established in {year}, PCBA Design has quickly risen to the top of the industry, serving a wide range of clients from various sectors including automotive, aerospace, medical, consumer electronics, and more. The company's commitment to excellence and customer satisfaction has earned it a reputation as a trusted and reliable partner for all PCB design and manufacturing needs.PCBA Design's success can be attributed to its team of highly skilled and experienced engineers and technicians who are dedicated to delivering top-notch solutions tailored to each client's specific requirements. The company's extensive experience in the field, combined with its relentless pursuit of innovation, has led to the development of cutting-edge technologies and processes that set it apart from its competitors.One of PCBA Design's key strengths lies in its ability to provide custom-tailored solutions that meet the unique needs of each client. Whether it's a simple single-layer circuit board or a complex multi-layered design, the company has the expertise and resources to deliver precisely what the client requires. This level of flexibility and customization has made PCBA Design a go-to partner for businesses looking to stay ahead of the curve in electronic design and manufacturing.In addition to its custom solutions, PCBA Design also offers a range of value-added services to further support its clients' needs. These services include design consultation, prototyping, testing, and full-scale production, allowing clients to benefit from a comprehensive and streamlined approach to their PCB requirements. The company's dedication to providing end-to-end solutions ensures that clients can rely on PCBA Design as a one-stop shop for all of their circuit board needs.Furthermore, PCBA Design places a strong emphasis on quality control and assurance throughout the entire manufacturing process. By adhering to strict standards and protocols, the company is able to consistently deliver products that meet and exceed industry expectations. This commitment to quality has earned PCBA Design numerous certifications and accolades, solidifying its position as a leading provider of high-quality circuit board solutions.Looking ahead, PCBA Design is poised to continue leading the way in the industry with its dedication to innovation and customer satisfaction. By staying at the forefront of technological advancements and industry trends, the company is well-positioned to meet the evolving needs of its clients and maintain its reputation as a top-tier PCB design and manufacturing partner.As the demand for advanced circuit board solutions continues to grow, PCBA Design remains committed to providing the highest level of service and expertise to its clients worldwide. With a strong track record of success and a clear vision for the future, the company is well-equipped to drive innovation and set new benchmarks for excellence in the industry.

Flexible Printed Circuits Measuring 0.3 Mm in Thickness Gain Popularity

[Publication Name] - [Date]0.3mm Flexible Printed Circuit (FPC) Revolutionizes Connectivity in an Ever-Advancing Technological LandscapeIn an era of constant technological evolution, the demand for ever-smaller, more flexible, and highly reliable electronic components has become paramount. Addressing this need head-on, an innovative company, renowned for pushing the boundaries of engineering advancements, has introduced their latest breakthrough: the 0.3mm Flexible Printed Circuit (FPC). Pioneering a new era of connectivity, this cutting-edge product is set to revolutionize electronic devices and transform industries across the globe.The 0.3mm FPC, produced by [Company Name], represents a significant leap forward in flexible circuit technology. This ultra-thin circuitry offers unrivaled flexibility, durability, and precise conductivity, making it the ideal solution for a wide range of applications. With the rapidly increasing popularity of wearable devices, IoT devices, and other compact electronic gadgets, the need for highly adaptable and efficient circuitry has never been greater. The introduction of the 0.3mm FPC is expected to meet this demand and fuel a wave of innovation across various industries.Key to the success of the 0.3mm FPC is its groundbreaking design. Leveraging state-of-the-art manufacturing techniques and advanced materials, [Company Name] has developed a product that maximizes space utilization while delivering enhanced performance and reliability. The ultra-thin nature of the circuit allows it to conform to any shape or contour, enabling seamless integration into devices of various form factors.The 0.3mm FPC boasts remarkable thermal and electrical conductivity, offering the stability required for the most demanding applications. Its low impedance design ensures reduced power losses and minimal signal degradation, bolstering the overall efficiency of electronic devices. Additionally, the FPC's high tensile strength guarantees resistance to bending, twisting, and vibration, making it highly robust and ensuring long-lasting performance in even the harshest environments.The wide-ranging applications of the 0.3mm FPC are endless. In the medical field, this breakthrough technology can revolutionize the way medical devices are designed and manufactured. With its flexibility and durability, the FPC can be seamlessly integrated into wearable health monitoring devices, bringing real-time patient data to healthcare professionals and improving overall patient care. Similarly, in the automotive industry, the FPC can power the next generation of smart vehicles, enabling advanced connectivity, intelligent infotainment systems, and enhanced safety features.Furthermore, the versatility of the 0.3mm FPC ensures its integration into consumer electronic devices such as smartphones, tablets, and smartwatches. With consumers demanding slimmer, lighter, and more functional devices, manufacturers can now utilize this ultra-thin circuitry to break design barriers and create truly innovative products.As a company committed to research and development, [Company Name] is dedicated to continuously improving the 0.3mm FPC and exploring new applications for its technology. With an extensive research team and cutting-edge manufacturing facilities, the company stands at the forefront of innovation, poised to shape the future of connectivity.In conclusion, the introduction of the 0.3mm Flexible Printed Circuit by [Company Name] marks a significant milestone in the field of circuitry technology. This revolutionary product sets new standards of flexibility, reliability, and performance, empowering industries to redefine connectivity and design. As the demand for smaller and more efficient electronic devices continues to grow, the 0.3mm FPC is poised to become an indispensable component, enabling a multitude of applications and propelling the world towards a more connected future.

Top 10 Toy PCBA Suppliers You Should Know About

Toy Company Launches Innovative Toy PCBA to Enhance User ExperienceToy Company is proud to announce the launch of its latest innovative product, the Toy PCBA. This cutting-edge technology is designed to enhance the user experience of the company's popular line of interactive toys, offering a new level of interactivity and customizability for children of all ages.The Toy PCBA is a printed circuit board assembly that can be easily integrated into the company's existing line of toys, adding a new dimension of play and learning. The PCBA is equipped with a range of sensors, including motion sensors and touch sensors, which allow for more intuitive and interactive play experiences. Additionally, the PCBA is programmable, allowing users to customize the behavior of their toys and create their own unique play experiences."We are thrilled to introduce the Toy PCBA to our customers," said [spokesperson] of Toy Company. "This technology represents a significant advancement in the interactive toy industry, offering a new level of engagement and creativity for children. We believe that the Toy PCBA will not only enhance the play experience for our existing customers but also attract new customers who are looking for innovative and customizable toys."In addition to enhancing the play experience, the Toy PCBA also has educational benefits. By allowing children to customize and program their toys, the PCBA encourages creativity, problem-solving, and STEM learning. This aligns with Toy Company's mission to provide toys that are not only fun but also educational and enriching.The Toy PCBA is compatible with a range of the company's existing toys, including interactive robots, building sets, and educational games. This versatility allows for endless possibilities in terms of play experiences and learning opportunities. The PCBA is also designed to be durable and easy to install, ensuring that it can withstand the rigors of play and seamlessly integrate into the company's existing toy designs.To accompany the launch of the Toy PCBA, Toy Company is also releasing a software development kit (SDK) that allows more advanced users to create their own custom programs for the PCBA. This opens up the potential for a community of users to share and collaborate on new toy experiences, further extending the possibilities of the technology."We believe that the release of the SDK will inspire a community of creative individuals to push the boundaries of what is possible with our Toy PCBA," said [spokesperson]. "We are excited to see the unique and imaginative programs that our customers will create, further showcasing the versatility and potential of this technology."The Toy PCBA is now available for purchase on the company's website and through select retail partners. Customers who already own compatible toys can also purchase the PCBA as an add-on to upgrade their existing toys.For more information about the Toy PCBA and to see a demonstration of its capabilities, visit the company's website. With the launch of this innovative technology, Toy Company is poised to continue leading the way in the interactive toy industry, offering products that inspire learning, creativity, and fun for children around the world.

Discover the Latest Innovations in Printed Circuit Board Technology

Printing Circuit Boards Boosts Production EfficiencyIn the age of digital advancement, printed circuit boards have become ubiquitous in a wide range of electronic devices. From smartphones to airplanes, these boards play a crucial role in the functioning of modern technology. However, the production of printed circuit boards has always been time-consuming and problematic for many manufacturers. With the invention of Printing Circuit Boards (PCBs), this issue may finally be resolved.PCBs are a new kind of circuit board technology that is changing the game for manufacturers all over the world. This technology involves the use of a printer to etch copper layers onto a substrate, which forms the circuit board's design. This process offers manufacturers a faster, more precise, and cost-effective way of producing printed circuit boards, compared to traditional methods, such as chemical etching.One such company that has brought this innovative technology to the market is (Brand name removed). The Yangzhou-based firm has been in the business of producing PCBs since 2003 and has set a new standard for the industry by introducing its range of printing circuit board products.According to the company's spokesperson, "We are delighted to bring this advanced technology to our customers. We believe that by introducing this new technology, we can help our clients achieve their targets in a faster, more effective way."With their Printing Circuit Boards, the company has streamlined their manufacturing process. Unlike the traditional methods, PCB printing requires no film or photoresist production. This advantage translates into faster production times and reduced overall costs.The company's innovative technology is backed up by its team of professionals who specialize in PCB design. With over 17 years of experience in the industry, the team has developed unique expertise in the development of high-quality PCBs. Some of the key services provided by the company's design team include custom designs, engineering solutions, and cost-effective PCB prototyping.Another major advantage of PCB printing is its compatibility with a wide range of electronic applications. The company's printing circuit boards are suitable for use in various devices, from simple household appliances to complex electronic systems used in industries such as aerospace, defense, and telecommunications.Furthermore, the novel technology used to manufacture the PCBs results in boards that are more durable and robust than those produced through traditional etching methods. These boards are designed to withstand wear and tear, and their high heat resistance capability ensures that they don't overheat when exposed to high temperatures.Recent research predicts that the global circuit board market will experience significant growth in the coming years, boosted by the rapid development of the internet of things (IoT) and other emerging technologies. (Brand name removed)'s PCB printing technology has positioned them to capitalize on this growth, as they seek to establish their position as a leading player in the global printed circuit board market.In conclusion, Printing Circuit Boards have revolutionized the way electronic manufacturers produce PCBs. The technology has streamlined the production process, reduced costs, and improved overall quality. The new way of producing printed circuit boards has broader implications as more and more companies look to incorporate this technology into their production process. As the benefits are numerous, PCB printing is proving to be the future of circuit board production, and (Brand name removed) is leading the way.

Latest developments in PCBA testing: Revolutionizing the electronic manufacturing industry

(Please note that as an AI language model, I don't have access to current news articles or specific brand information. Therefore, I will provide you with a generic example of an 800-word news article about PCBA testing.)Title: Streamlining Quality Control: The Role of PCBA TestingIntroduction:In today's fast-paced and technology-driven world, electronic devices play a vital role in our everyday lives. From smartphones to smart home devices, the demand for high-quality electronic products keeps increasing. As manufacturers strive to meet this demand, ensuring the reliability and functionality of printed circuit board assemblies (PCBAs) becomes paramount. That's where PCBA testing comes into play, an integral part of the quality control process for electronic components.PCBA Testing: A Brief OverviewPCBA testing is a comprehensive quality control method that examines the functionality and reliability of printed circuit board assemblies. By conducting various tests and inspections, PCBA testing verifies the overall performance, accuracy, and durability of electronic devices. This meticulous testing process ensures that only defect-free PCBAs reach the market, minimizing the chances of product failures and enhancing overall customer satisfaction.The Importance of PCBA Testing:1. Enhancing Product Reliability:PCBAs are the building blocks of electronic devices. defects within these components can lead to functional errors, malfunctions, or even safety hazards. By subjecting PCBAs to rigorous testing processes, manufacturers can identify and rectify defects before the products hit the market, ensuring their reliability and reducing the risk of recalls.2. Quality Control at Early Stages:Incorporating PCBA testing during the early stages of the manufacturing process allows manufacturers to detect and rectify defects promptly. By identifying weak electronic connections, inaccurate component placements, or faulty soldering joints, the testing process minimizes the need for rework and reduces production costs.3. Ensuring Consistency:Each PCBA requires the same level of performance and quality. PCBA testing ensures consistent quality across multiple units, thus maintaining high standards throughout the production cycle.4. Regulatory Compliance:With stringent regulations governing the electronic industry, PCBA testing plays a significant role in ensuring compliance with safety standards and regulations. By meeting these requirements, manufacturers can avoid legal complications and safeguard consumer trust.PCBA Testing Methods:1. In-Circuit Testing (ICT):In-Circuit Testing is a popular PCBA testing method that examines the electrical integrity of individual components, checking for shorts, opens, or incorrect component values. Conducted with the help of test fixtures and probes, ICT significantly reduces the time required for testing and provides a comprehensive analysis of the PCBA's functionality.2. Functional Testing (FCT):Functional Testing evaluates the PCBA's overall functionality, simulating real-world conditions to verify that the device performs as intended. By subjecting PCBAs to a series of functional tests, manufacturers can validate components such as memory, interfaces, and power management. FCT helps identify any potential defects related to software integration or hardware compatibility.3. Environmental Testing:Environmental stress tests assess the PCBA's ability to withstand extreme conditions such as temperature variations, humidity, vibration, or mechanical shock. These tests ensure the reliability and durability of PCBAs under challenging environmental circumstances.Conclusion:In the ever-evolving electronic industry, PCBA testing plays a crucial role in ensuring the quality, reliability, and functionality of electronic devices. By incorporating comprehensive testing methodologies like In-Circuit Testing, Functional Testing, and Environmental Testing, manufacturers can streamline their quality control process, minimize product defects, and enhance customer satisfaction. As new technologies continue to emerge, PCBA testing will remain a vital component in delivering innovative, high-quality electronic devices to the market.

Nan241l872: Unveiling the Latest News and Updates Regarding...

Title: Nan241l872 Revolutionizes the Industry with Innovative TechnologyIntroduction:In today's dynamic and fast-paced world, technological advancements continue to shape and transform various industries. One prominent player in this wave of innovation is Nan241l872 (brand name removed), a leading company that is revolutionizing multiple sectors with its cutting-edge technologies. With a firm commitment to pushing the boundaries of what is possible, Nan241l872 has consistently delivered ground-breaking solutions that have disrupted and transformed the status quo. This article will explore some of Nan241l872's key innovations and their impact on industries worldwide.1. The Rise of Nan241l872:Established in the early 2000s, Nan241l872 has emerged as a force to be reckoned with in the world of technology. Driven by a passion for innovation, the company's dedicated team of researchers, engineers, and designers have consistently pushed the boundaries of possibility. Their unwavering commitment to excellence has earned Nan241l872 recognition as a pioneer in the field.2. Revolutionizing the Automotive Sector:Nan241l872's groundbreaking developments have had a profound impact on the automotive sector. The company's advanced sensors and AI-powered autonomous driving technology have transformed the way we travel. These innovations offer increased safety and efficiency, while also reducing the carbon footprint of vehicles. Nan241l872's partnerships with major automakers have made autonomous driving a reality, and the company continues to drive the industry forward.3. Transforming Healthcare:In the healthcare sector, Nan241l872's innovations have brought about significant advancements. The company's state-of-the-art medical devices have revolutionized diagnoses and treatment plans. Nan241l872's cutting-edge imaging technology provides highly detailed and accurate images, aiding physicians in making more precise diagnoses. Additionally, the company's advancements in robotics have enhanced surgical procedures, resulting in reduced invasiveness and faster recovery times for patients.4. Reshaping the Energy Landscape:Nan241l872's commitment to sustainable technology is also evident in its contributions to the energy sector. Through advancements in renewable energy solutions, such as solar panels and energy storage systems, Nan241l872 is playing a pivotal role in transitioning to a cleaner and greener future. Their state-of-the-art energy storage technologies enable efficient use of renewable energy, making it more accessible and cost-effective.5. Enhancing Consumer Electronics:Nan241l872 has had a significant impact on our everyday lives through its advancements in consumer electronics. From high-resolution displays to energy-efficient batteries, the company's innovations have made our devices smarter, faster, and more sustainable. Nan241l872's focus on improving user experiences has resulted in sleek designs and enhanced functionality across various electronic devices.6. Pioneering Research and Development:Nan241l872 has always prioritized research and development, dedicating substantial resources to exploring emerging technologies. By fostering a culture of innovation and collaboration, the company continuously seeks to unveil the next groundbreaking solutions. Nan241l872's commitment to ongoing research ensures its ability to anticipate and meet the evolving needs of industries and consumers alike.Conclusion:As Nan241l872 continues to push the boundaries of possibility across various industries, its innovative technologies are reshaping the world we live in. From the automotive sector to healthcare, energy, and consumer electronics, Nan241l872's groundbreaking advancements have revolutionized multiple industries. By staying at the forefront of technological innovation, Nan241l872 is paving the way for a future that is smarter, greener, and more efficient.

Leading Electronic Manufacturing Company Offers Quality PCBA OEM Services" can be rewritten to "Get Professional PCBA OEM Services from a Reliable Electronic Manufacturing Company".

PCBA OEM Introduces Innovative Electronic Manufacturing Solutions to Help Companies Achieve a Competitive EdgeIn today's dynamic business environment, companies in various industries need to stay competitive to survive and thrive. One way to achieve a competitive edge is by leveraging innovative technological solutions. That is why PCBA OEM is proud to announce its cutting-edge electronic manufacturing solutions that are designed to help companies accelerate their growth, reduce costs, and improve efficiency.PCBA OEM is a leading end-to-end electronics manufacturing service provider that specializes in delivering comprehensive turnkey solutions to customers worldwide. The company caters to diverse industries, including but not limited to automotive, healthcare, consumer electronics, and industrial automation. Since its inception, PCBA OEM has been committed to providing unmatched quality, timeliness, and customer support to its clients.At the heart of PCBA OEM's success is its state-of-the-art manufacturing facility in Asia, which is equipped with advanced technologies and managed by an experienced team of professionals. The facility is ISO 9001:2015, ISO 14001:2015, and IATF 16949:2016 certified, ensuring that all products are manufactured to the highest standards of quality and compliance.PCBA OEM's electronic manufacturing services encompass the entire product lifecycle, from design and prototyping to mass production and after-sales support. The company's engineering team works closely with customers to understand their unique requirements and specifications. They use various design tools and software, such as Autodesk Eagle, Altium Designer, and OrCAD, to create customized PCB layouts, schematics, and 3D models.Once the design is finalized, PCBA OEM's prototyping service fabricates the first working prototype, which is then rigorously tested for functionality, reliability, and performance. The company's manufacturing service then takes over, leveraging its advanced equipment and processes to produce high-quality PCB assemblies in large quantities. The manufacturing process includes surface mount technology, through-hole technology, and mixed technology, depending on the product's complexity and requirements.PCBA OEM's commitment to quality goes beyond manufacturing. The company conducts various tests, such as in-circuit testing, functional testing, and X-ray inspection, to ensure that every product meets or exceeds customer expectations. Moreover, PCBA OEM adheres to strict supply chain management practices to ensure that all components and materials used in its products are sourced from reputable suppliers who meet international standards.PCBA OEM's electronic manufacturing solutions are not just about delivering high-quality products; they are also about adding value to customers' businesses. The company offers various value-added services, such as customization, packaging, labeling, and logistics, to help customers reduce costs, improve efficiency, and enhance their brand's image. For instance, PCBA OEM can package products in custom boxes, add branding and labeling, and even handle the product's shipping and fulfillment.What sets PCBA OEM apart from other electronic manufacturing service providers is its customer-centric approach. The company's team of professionals communicates transparently and frequently with customers, keeping them informed of project progress, addressing any concerns or issues promptly, and providing timely solutions. PCBA OEM also offers flexible pricing models and manages projects in a cost-effective manner, enabling customers of all sizes and budgets to access its services.In conclusion, PCBA OEM's electronic manufacturing solutions are designed to help companies achieve a competitive edge. By leveraging the company's expertise, experience, and advanced technologies, customers can develop and produce high-quality electronic products that meet their business objectives. PCBA OEM is committed to delivering value, quality, and reliability to its customers and looks forward to partnering with more businesses to foster growth and success.