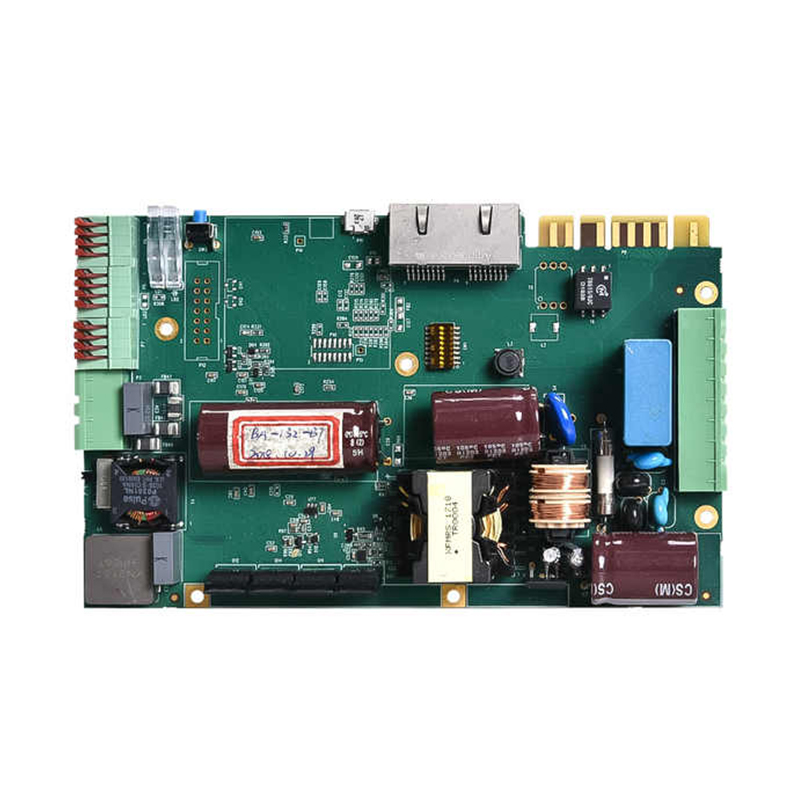

Expert Tips for High-Quality PCB Assembly

By:Admin

{} was founded in [year] and has since become a key player in the electronics manufacturing industry. The company prides itself on its ability to deliver high-quality PCB assembly services to a wide range of clients, including those in the automotive, medical, aerospace, and consumer electronics industries. Their commitment to excellence and customer satisfaction has earned them a stellar reputation in the industry.

One of the key factors that sets {} apart from other PCB assembly service providers is their dedication to using the latest technology and equipment. They have invested heavily in cutting-edge machinery that is capable of producing high-precision PCB assemblies with quick turnaround times. This allows them to meet the needs of clients who require fast and reliable PCB assembly services.

In addition to their technological capabilities, {} also places a strong emphasis on the skills and expertise of their team. Their team of engineers and technicians are highly trained and experienced in all aspects of PCB assembly, from design and layout to manufacturing and testing. This combination of advanced technology and skilled personnel ensures that {} is able to consistently deliver top-quality PCB assemblies to their clients.

Furthermore, {} is dedicated to maintaining the highest standards of quality control throughout the PCB assembly process. They adhere to strict quality assurance protocols to ensure that every PCB assembly that leaves their facilities meets the highest industry standards. This commitment to quality has made them a trusted partner for many companies seeking reliable PCB assembly services.

One of the key advantages of working with {} is their ability to provide customized solutions to meet the unique needs of each client. They understand that every project is different and requires a tailored approach to PCB assembly. Whether a client requires a small prototype run or a large-scale production run, {} has the capabilities and flexibility to accommodate their needs.

The company's commitment to customer satisfaction has allowed them to build lasting relationships with many of their clients. They take the time to understand each client's specific requirements and work closely with them throughout the PCB assembly process to ensure that their expectations are not only met but exceeded.

With the continued growth of the electronics industry, the demand for high-quality PCB assembly services is expected to remain strong. As a trusted and reliable provider in the industry, {} is well-positioned to meet this demand and continue to provide exceptional PCB assembly services to their clients.

In conclusion, {} is a leading provider of high-quality PCB assembly services with a proven track record of delivering top-notch products to a diverse range of industries. Their investment in state-of-the-art technology, skilled team, and commitment to quality and customer satisfaction has cemented their position as a trusted partner for companies seeking reliable PCB assembly services. As the demand for electronic products continues to grow, {} is well-equipped to meet the needs of the industry and continue to provide exceptional PCB assembly services to their clients.

Company News & Blog

High-quality LED Light Circuit Board for Efficient Lighting

There has been a recent breakthrough in the world of electronics, as a leading company in the industry has developed a cutting-edge Led Light Circuit Board. This innovative advancement represents a significant step forward in the field of lighting technology, and has the potential to revolutionize the way we use and interact with light.The Led Light Circuit Board, developed by a company with a strong track record of pushing the boundaries of technology, is set to redefine the way we think about lighting. By harnessing the power of LED technology, this circuit board is capable of delivering bright and efficient light in a package that is smaller and more versatile than ever before.One of the key features that sets this Led Light Circuit Board apart from its predecessors is its compact and lightweight design. This means that it can be easily integrated into a wide range of products, from traditional light fixtures to more specialized applications such as automotive lighting and wearable technology. By providing a high level of brightness and efficiency in a small form factor, this circuit board opens up new possibilities for designers and engineers looking to push the boundaries of what is possible with lighting.Furthermore, the Led Light Circuit Board is also highly customizable, allowing for a high degree of flexibility in terms of the color and intensity of the light it produces. This opens up a wide range of potential use cases, from creating ambient mood lighting to providing powerful illumination for industrial and commercial settings. With the ability to tailor the output of the circuit board to suit specific needs and requirements, it is well positioned to become a go-to solution for a wide range of lighting applications.In addition to its impressive technical capabilities, the company behind the Led Light Circuit Board has a long history of delivering high-quality and reliable products to its customers. With a strong focus on research and development, as well as a commitment to staying at the forefront of technological innovation, this company has a proven track record of pushing the boundaries of what is possible with electronics. This dedication to excellence and continuous improvement bodes well for the future of the Led Light Circuit Board, and instills confidence in its potential to make a significant impact on the lighting industry.Looking ahead, the future of lighting technology appears brighter than ever thanks to the development of the Led Light Circuit Board. By leveraging the power of LED technology and combining it with a compact and customizable design, this circuit board has the potential to change the way we think about and interact with light. Whether it's creating more efficient and sustainable lighting solutions, or opening up new possibilities for innovative product designs, the Led Light Circuit Board is set to make a lasting impression on the world of electronics. With the support of a company that is dedicated to pushing the boundaries of what is possible with technology, the future looks very bright indeed for this groundbreaking innovation.

Ultimate Guide to PCB Electronics in 2021: Everything You Need to Know

PCB Electronics, a leading provider of electronic manufacturing services, recently announced the launch of their new state-of-the-art facility in [Location]. This new facility represents a significant investment in expanding their production capacity and capabilities to better serve their clients in the rapidly evolving electronics industry.With over 20 years of experience in the electronics manufacturing industry, PCB Electronics has established a solid reputation for delivering high-quality products and exceptional customer service. The company has built a strong customer base by offering a wide range of services including PCB assembly, box build assembly, testing, and engineering support.The new facility is equipped with the latest technology and machinery to ensure efficient production processes and high-quality output. It includes advanced automated assembly lines, precision testing equipment, and a dedicated engineering team to support product development and customization. The facility also adheres to strict quality control measures to meet industry standards and client requirements.In addition to expanding their manufacturing capabilities, PCB Electronics is also committed to sustainability and environmental responsibility. The new facility has been designed with environmentally friendly practices in mind, including energy-efficient systems and waste management strategies. The company is dedicated to minimizing its environmental footprint and promoting a greener approach to manufacturing.The expansion of PCB Electronics' production capacity comes at a time of increasing demand for electronic components and devices. The electronics industry is experiencing rapid growth driven by technological advancements, consumer demand, and emerging trends such as IoT (Internet of Things) and smart devices. With the new facility, PCB Electronics is well-positioned to meet the growing needs of their clients and continue to be a trusted partner in the industry.The company's dedication to quality, innovation, and customer satisfaction has been key to their success and will continue to drive their growth in the future. By investing in state-of-the-art facilities and maintaining a strong focus on sustainability, PCB Electronics is poised to be a leader in the electronic manufacturing services industry for years to come.In response to the opening of the new facility, CEO of PCB Electronics, [Name], expressed his enthusiasm and confidence in the company's future. "We are excited to announce the opening of our new facility, which represents a significant milestone for our company. This expansion is a testament to our commitment to delivering the best possible products and services to our clients. We are confident that this new facility will allow us to better serve our customers, meet growing demand, and continue to drive innovation in the electronics industry."The opening of the new facility is a significant development for PCB Electronics and underscores their commitment to growth, innovation, and sustainability. As the company continues to expand its capabilities and reach, it is well-positioned to remain a leader in the electronic manufacturing services industry and meet the evolving needs of clients in a rapidly changing market.

New 0.5 Mm Flexible Printed Circuit (FPC) Technology Unveiled with Exciting Innovations

Title: Leading Electronics Manufacturer Introduces Cutting-Edge 0.5 mm FPC ConnectorsIntroduction:In an era increasingly driven by technological advancements, the demand for sleek and compact electronic devices continues to rise. To meet this growing need, [Company Name], a renowned leader in electronics manufacturing, is proud to introduce its latest innovation, the revolutionary 0.5 mm FPC connector. Developed to enhance the flexibility and efficiency of electronic products, this cutting-edge technology is set to revolutionize the industry.[Company Name] - A Pioneer in Electronics Manufacturing:With decades of experience and a stellar reputation, [Company Name] has emerged as a trusted name in the electronics industry. Known for their commitment to innovation and superior quality products, the company has consistently pushed boundaries to develop state-of-the-art solutions for a wide range of applications. From consumer electronics to automotive and medical devices, [Company Name] has established itself as a key player across various sectors.The 0.5 mm FPC Connector: A Remarkable Engineering Feat:The newly launched 0.5 mm FPC connector exemplifies [Company Name]'s unwavering dedication to research and development. This groundbreaking invention is designed to support the growing need for flexible printed circuit (FPC) connectors, where space constraints demand ultra-compact solutions without compromising performance.The compact size of the 0.5 mm FPC connector ensures compatibility with an array of electronic devices, enabling seamless integration into the latest generation of smartphones, tablets, wearables, and other IoT devices. Electronics manufacturers will appreciate its slim form factor, which not only optimizes space but also simplifies manufacturing processes.Enhancing Flexibility and Reliability:One of the key advantages of the 0.5 mm FPC connector is its exceptional flexibility. This innovative technology allows for a higher degree of bending and folding, thereby accommodating various orientations within electronic devices. This enhanced flexibility empowers designers and engineers to create thinner, lighter, and more ergonomic products.Furthermore, the 0.5 mm FPC connector is engineered using high-quality materials that guarantee reliable and uninterrupted data transmission. With its superior electrical conductivity and robust construction, this connector ensures secure signal integrity, minimizing the risk of data loss or malfunctions. Manufacturers can now produce devices that deliver seamless performance, meeting the ever-increasing demands of consumers.Incorporating Advanced Features:[Company Name] understands the evolving needs of the electronics industry, and thus, the 0.5 mm FPC connector is equipped with additional advanced features. For instance, it employs gold-plated contact pads to ensure superior conductivity, while a ruggedized design enhances durability and resistance to environmental factors such as moisture and temperature variations.Furthermore, the connector's low insertion force simplifies installation, reducing the risk of damage and enabling efficient assembly processes. These features collectively enhance manufacturing efficiency and yield high-quality end products.Global Customer Reach and Customization Options:As a globally recognized brand, [Company Name] is dedicated to meeting the unique requirements of its diverse customer base. The 0.5 mm FPC connector will be readily available to electronic manufacturers worldwide, ensuring seamless integration into products produced across the globe.Additionally, [Company Name] offers customization options for the 0.5 mm FPC connector, allowing customers to tailor the solution to their specific needs. This flexibility enables electronics manufacturers to achieve optimal performance and compatibility with their respective products while streamlining their supply chain.A Visionary Step Towards the Future:The introduction of the 0.5 mm FPC connector by [Company Name] marks another significant milestone in the field of electronics manufacturing. With its exceptional flexibility, reliability, and advanced features, this revolutionary connector paves the way for next-generation electronic devices that are smaller, faster, and more efficient.As consumer demand for compact and feature-rich electronic products continues to grow, [Company Name] remains committed to driving innovation and providing cutting-edge solutions to meet evolving market needs. With the exceptional 0.5 mm FPC connector, [Company Name] reaffirms its position as a leading force in the electronics industry, empowering manufacturers to build a brighter, more connected future.

Discover the Advantages of 0.5mm FFC: Unveiling the Perfect Solution for Seamless Connectivity

[Company Name] Expands Product Line with Introduction of Innovative 0.5 mm FFC Cable[City, State] - [Date] – [Company Name], a leading manufacturer and supplier of electronic components, is proud to announce the launch of its latest product - the groundbreaking 0.5 mm FFC (Flexible Flat Cable). This innovative cable solution offers a unique combination of flexibility, durability, and high-performance, making it an ideal choice for a wide range of applications in various industries.Flexible Flat Cables (FFCs) have revolutionized the world of electronics, enabling the production of sleek, compact devices with complex internal wiring. These cables, known for their flat, ribbon-like structure, are commonly used in applications where space and weight are critical, such as laptops, digital cameras, smartphones, and automotive electronics.The newly introduced 0.5 mm FFC from [Company Name] boasts an array of impressive features. Designed to meet the industry's ever-increasing demands, this cable provides enhanced performance capabilities, ensuring reliable signal transmission and optimal connectivity. Its slim and lightweight design enables efficient use of space within electronic devices, contributing to their overall compactness and portability.One of the key features of the 0.5 mm FFC is its exceptional flexibility. Unlike traditional round cables, FFCs can be bent, folded, and twisted without compromising their functionality or longevity. The flexibility of the 0.5 mm FFC allows it to navigate tight spaces and intricate designs, offering manufacturers greater freedom in product development. This flexibility is particularly valuable in applications that require constant or repeated movement, such as hinges, sliding mechanisms, and robotic arms.In addition to its flexibility, the 0.5 mm FFC exhibits outstanding durability. It is engineered to withstand a wide temperature range, ensuring reliable performance under extreme conditions. Its robust design reduces the risk of cable damage or failure due to tears, abrasions, or bending stress, guaranteeing prolonged product lifespan. This durability makes the 0.5 mm FFC an excellent choice for applications exposed to harsh operating environments or constant use.Furthermore, [Company Name] utilizes advanced manufacturing processes and high-quality materials to produce the 0.5 mm FFC. Each cable undergoes rigorous testing to meet industry standards and customer expectations. For added convenience, the company offers customizable options, including varying lengths, connectors, and pin arrangements, ensuring compatibility with diverse devices and specifications.The introduction of the 0.5 mm FFC is a testament to [Company Name]'s commitment to providing cutting-edge solutions to its customers. The company's continuous investment in research and development, combined with its expertise in electronic component manufacturing, allows it to stay at the forefront of technological advancements. The 0.5 mm FFC represents a significant milestone in [Company Name]'s product portfolio expansion, catering to the evolving needs of various industries.[Company Name]'s dedication to innovation and customer satisfaction has earned it a reputation as a trusted partner within the electronics industry. With the introduction of the 0.5 mm FFC, the company aims to further solidify its position as a leading provider of high-quality, dependable electronic components.About [Company Name]:[Company Name] is a renowned manufacturer and supplier of electronic components, offering a wide range of solutions to meet the ever-changing demands of the electronics industry. With a focus on quality, innovation, and customer satisfaction, the company has established itself as a trusted partner to numerous customers worldwide. [Company Name]'s commitment to excellence is reflected in its diverse product portfolio, which includes connectors, cables, sensors, displays, and more.For further information about [Company Name] and its product offerings, please visit [website].

Discover the Latest News on a Prominent FPC Hotbar

It has recently been announced that Hotbar Fpc, a leading manufacturer of flexible circuit boards, has partnered with several prominent electronics companies to offer cutting-edge solutions in the electronics industry. The collaboration is set to benefit the companies involved as well as the industry at large.Hotbar Fpc is a renown manufacturer of flexible circuit boards, which are an essential component in many electronic devices. Their products are known for their conducive design, durability and flexibility, and have gained popularity in various applications, including consumer electronics, automotive, aerospace, medical equipment, and many others.With their extensive experience and expertise in the industry, Hotbar Fpc has partnered with companies that share their commitment to innovation and excellence in the electronics industry. Through this collaboration, they aim to explore new technologies and advances that will enhance the effectiveness of their products while ensuring that clients receive quality services.One of the companies that Hotbar Fpc has partnered with is Yokowo, a global manufacturer of electronic components. Their joint venture will focus on developing technologies for smart wearables and other portable devices. The partnership aims to create flexible circuit boards that integrate seamlessly with different wearable devices, revolutionizing the way people interact with technology.Another company partnering with Hotbar Fpc is TE Connectivity, a world leader in connectivity and sensor solutions. Together, they aim to develop high-temperature applications for the aerospace industry. Their mission is to create flexible circuit boards that are durable, dependable and can withstand the harsh environments that aerospace components operate in.Flex, a Singapore-based electronics manufacturing company, is also collaborating with Hotbar Fpc. Their joint venture is focused on developing advanced technologies for the automotive industry. Hotbar Fpc's expertise in flexible circuit boards, combined with Flex's manufacturing expertise, would enable them to create innovative electronics that can support the latest advancements in the automotive industry.Through these partnerships, Hotbar Fpc aims to enhance their capabilities in the industry while collaborating with like-minded companies. By working together, they can develop better solutions, enhance their research and development efforts, and provide clients with more advanced products that meet their needs.Hotbar Fpc is renowned for its commitment to quality, ensuring their flexible circuit boards meet their clients' unique demands. The company's dedication to innovation and excellence has enabled it to remain at the forefront of the industry, and their partnerships aim to strengthen this position. Hotbar Fpc believes that by collaborating with other leading companies in the electronics industry, they can continue to offer the best solutions to their clients.In conclusion, the partnership between Hotbar Fpc and some of the prominent electronics companies is poised to bring significant improvements to the industry. The collaborations will not only benefit the companies involved but also improve the overall technology and services offered by the industry. The flexibility, durability and conducive design of Hotbar Fpc's flexible circuit boards are set to meet the increasing demand for advanced electronic solutions, thus driving the growth of the industry. As their joint venture progresses, it's expected that the collaborations will result in innovations that will benefit different industries and wider society.

Guide to Multilayer PCBs: What You Need to Know

Fr4 Multilayer PCB Market Growth Predicted at a Notable CAGR During 2021 - 2026The global Fr4 Multilayer PCB market is projected to witness a significant growth rate during the forecast period of 2021-2026, as estimated by a new market research report. The report on the Fr4 Multilayer PCB market offers an in-depth analysis of the market landscape, including the drivers and restraints, opportunities, and challenges. It also provides a comprehensive overview of the competitive landscape and strategies that impact the market growth.The Fr4 Multilayer PCB is a type of printed circuit board with multiple layers of copper foil, laminated together with an epoxy resin. This type of PCB is widely used in applications where high-density interconnects are required, including telecommunications, medical devices, consumer electronics, and automotive industry. The demand for Fr4 Multilayer PCB is expected to surge with the increasing adoption of advanced technologies and the growing need for compact and lightweight electronic devices.{Company Name} is a leading manufacturer of Fr4 Multilayer PCB, offering a wide range of products that cater to the diverse needs of the industry. Established in {year}, the company has built a strong reputation for its commitment to quality, innovation, and customer satisfaction. With state-of-the-art manufacturing facilities and a dedicated team of experts, {Company Name} has continuously raised the bar in delivering high-performance and reliable Fr4 Multilayer PCB solutions to its global clientele.The company takes pride in its ability to customize its products to meet the specific requirements of its customers. Whether it's a complex PCB design or a high-volume production, {Company Name} has the expertise and capabilities to deliver cost-effective and high-quality solutions. With a focus on research and development, the company stays ahead of the curve in developing cutting-edge PCB technologies that offer enhanced performance, durability, and reliability.The global Fr4 Multilayer PCB market is witnessing significant growth due to the rapid advancement in technology and increasing demand for smart and connected devices. The adoption of Fr4 Multilayer PCB is expected to escalate as industries continue to embrace automation, IoT, and artificial intelligence. The need for high-speed data transmission, miniaturization, and improved signal integrity are driving the demand for Fr4 Multilayer PCB in various applications.{Company Name} stands out as a leader in the Fr4 Multilayer PCB market, offering a comprehensive portfolio of products that meet the stringent quality standards and industry specifications. The company's commitment to sustainability and environmental responsibility is reflected in its manufacturing processes and product offerings. {Company Name} is dedicated to reducing its environmental footprint and promoting eco-friendly practices throughout its operations.The company's relentless pursuit of excellence has earned it a strong foothold in the global market, with a loyal customer base that spans across different industries and regions. As the demand for Fr4 Multilayer PCB continues to grow, {Company Name} is well-positioned to capitalize on the opportunities and strengthen its market presence. With a focus on customer satisfaction and continuous innovation, the company is poised for sustained growth and success in the years to come.In conclusion, the global Fr4 Multilayer PCB market is poised for remarkable growth, driven by the increasing demand for advanced electronic devices and technologies. {Company Name} emerges as a key player in the market, offering top-notch Fr4 Multilayer PCB solutions that address the evolving needs of the industry. With a strong focus on quality, innovation, and customer-centric approach, {Company Name} is set to make a significant impact in the Fr4 Multilayer PCB market and contribute to the advancement of electronic technologies.

How to Connect a PCB Board: A Step-by-Step Guide

Pcb Board Connection, a leading provider of innovative printed circuit board (PCB) solutions, has announced the launch of a new line of advanced PCB boards designed to meet the evolving needs of the electronics industry. With a commitment to quality, reliability, and innovation, Pcb Board Connection has a strong track record of delivering cutting-edge PCB solutions to a wide range of industries, including automotive, consumer electronics, telecommunications, and medical devices.The new line of PCB boards from Pcb Board Connection incorporates the latest advancements in technology and materials to provide customers with high-performance, reliable, and cost-effective solutions. These boards are designed to meet the increasing demand for smaller, lighter, and more powerful electronics, while also delivering improved thermal performance and signal integrity."We are excited to introduce our new line of advanced PCB boards, which are the result of years of research and development," said the CEO of Pcb Board Connection. "We understand the challenges facing our customers in today's fast-paced and competitive market, and we are dedicated to providing them with the highest quality PCB solutions that meet their specific needs."In addition to the new line of advanced PCB boards, Pcb Board Connection offers a wide range of services to support its customers throughout the entire product development process. This includes design and layout assistance, prototyping, testing, and ongoing technical support. With a team of experienced engineers and a state-of-the-art manufacturing facility, Pcb Board Connection is well-equipped to handle projects of any size and complexity.One of the key advantages of working with Pcb Board Connection is the company's commitment to quality and reliability. All of its PCB boards are manufactured to the highest industry standards and undergo rigorous testing to ensure consistent performance and durability. This commitment to quality has earned Pcb Board Connection a strong reputation for producing reliable and dependable PCB solutions.Furthermore, Pcb Board Connection is dedicated to sustainability and environmental responsibility. The company utilizes environmentally friendly materials and manufacturing processes to minimize its impact on the environment. By partnering with Pcb Board Connection, customers can be confident that they are choosing a supplier that shares their commitment to sustainability."We take our responsibility to the environment very seriously, and we are constantly seeking ways to minimize our environmental footprint," said the CEO. "By choosing Pcb Board Connection as their PCB supplier, customers can rest assured that they are supporting a company that prioritizes sustainability and environmental stewardship."As the electronics industry continues to evolve and demand for advanced PCB solutions grows, Pcb Board Connection remains at the forefront of innovation. The company is committed to staying ahead of industry trends and developing new technologies to meet the evolving needs of its customers. With its new line of advanced PCB boards and dedication to quality, reliability, and sustainability, Pcb Board Connection is well-positioned to continue serving as a trusted partner for customers across a wide range of industries.For more information about Pcb Board Connection and its advanced PCB solutions, visit {}.In conclusion, Pcb Board Connection is a leading provider of innovative PCB solutions, and with the launch of its new line of advanced PCB boards, the company is poised to meet the evolving needs of the electronics industry. With a commitment to quality, reliability, and sustainability, Pcb Board Connection is well-positioned to continue serving as a trusted partner for customers in a wide range of industries.

Optimize Your PCBA SMT for Efficient Assembly and Production

Title: PCBA SMT: Revolutionizing Electronics Manufacturing TechnologyIntroduction:In today's fast-paced digital world, the demand for technologically advanced and efficient electronic devices is soaring. Meeting this demand requires state-of-the-art manufacturing processes that can produce intricate circuit boards seamlessly. This is where PCBA Surface Mount Technology (SMT) comes in. Its ability to revolutionize the electronics manufacturing process has made it an indispensable solution for numerous industries.PCBA SMT: A Brief OverviewPCBA SMT, short for Printed Circuit Board Assembly Surface Mount Technology, is a cutting-edge method used to mount and solder electronic components onto PCBs. Unlike traditional through-hole technology, SMT technology places components directly onto the surface of the board, eliminating the need for drilling holes and allowing for denser packing of components.Overcoming Traditional LimitationsBefore the advent of PCBA SMT, the through-hole technology posed several challenges. As electronic devices became increasingly complex and compact, drilling holes became more difficult and time-consuming. Additionally, through-hole technology limited the number of components that could be placed on a board due to space constraints. Through PCBA SMT, these limitations have been successfully overcome.Enhanced Efficiency and PrecisionPCBA SMT offers increased efficiency by automating the assembly process. Placement machines accurately position electronic components, resulting in greater precision and overall product quality. This automation significantly reduces the risk of human error and ensures consistent production standards, resulting in less rework and improved time-to-market.Minimizing Size, Maximizing PotentialOne of the most significant advantages of PCBA SMT is its ability to shrink the size of electronic devices while maximizing their functionality. As components can be positioned more closely together, PCBs can be smaller, lighter, and more powerful. This reduction in size allows for the development of sleeker, portable gadgets without compromising performance.Improved Thermal PerformancePCBA SMT technology excels in thermal management, ensuring efficient heat dissipation. By mounting components directly onto the board's surface, heat generated during operation is efficiently transferred to the PCB, reducing the risk of overheating. This feature is particularly crucial for high-performance devices, such as gaming consoles, servers, and medical equipment.Flexibility and VersatilityPCBA SMT's versatility makes it the preferred choice for a wide range of industries. From consumer electronics and automotive to telecommunications and aerospace, this technology can adapt to various manufacturing requirements. Its flexibility allows for the integration of advanced features such as wireless connectivity, IoT capabilities, and even AI integration in modern devices.The Future of PCBA SMTAs the demand for smaller, smarter, and more connected devices continues to grow, PCBA SMT faces an exciting future. Manufacturers are constantly pushing the boundaries of innovation, seeking ways to enhance production speed, reduce costs, and improve overall efficiency. Some latest advancements include robotics integration, 3D printing components, and the utilization of highly efficient soldering techniques.ConclusionPCBA SMT continues to revolutionize the electronics manufacturing industry by offering improved efficiency, precision, and flexibility. With its ability to achieve smaller form factors, enhanced thermal management, and adaptability to diverse manufacturing demands, PCBA SMT has become an indispensable technology for numerous industries. As we embrace a future full of smart solutions, PCBA SMT is set to play a vital role in driving innovation, making our lives more connected and convenient.

Revolutionary Sticker Offers Innovative Solution - Unveiled in Recent News

As a company that is dedicated to producing high-quality products, we are excited to announce our latest invention - the Fpc Sticker. This innovative sticker is designed to provide a versatile and practical solution for all your labeling needs.The Fpc Sticker is a multipurpose adhesive label that is designed for use across a range of industries. It has been developed with a strong backing that provides a firm grip on any surface, making it suitable for a wide range of applications.One of the key features of our Fpc Sticker is its compatibility with a variety of printers. This makes it easy to customize the labels to meet your specific branding needs. Our product is compatible with both inkjet and laser printers and can be printed in full color. This flexibility ensures that you can create custom labels that are tailored to your business needs.The Fpc Sticker is also designed to be highly durable. It is resistant to water and chemicals, providing a long-lasting labeling solution that won't fade or peel over time.One of the key advantages of the Fpc Sticker is its ease of use. It is designed to be user-friendly, making it easy for anyone to create professional-looking labels. Our product comes with an easy-to-use software program that allows you to design your labels with minimal effort. You can also use pre-designed templates to make the process even easier.Our Fpc Sticker is also environmentally friendly. We have designed it to be made from eco-friendly materials, ensuring that our product has a minimal impact on the environment. By using our Fpc Sticker, you can ensure that your business is doing its part to reduce environmental harm.Our Fpc Sticker is available in a range of sizes and shapes, making it suitable for a variety of applications. Whether you need to label products, packaging, or equipment, our product provides a practical labeling solution that offers durability and flexibility.As a company, we are dedicated to providing our customers with innovative products that meet their unique business needs. Our Fpc Sticker is just one example of our commitment to providing practical solutions that make a real difference to our customers.In summary, our Fpc Sticker is an innovative, practical, and user-friendly labeling solution that is suitable for a wide range of applications. Its versatility, durability, and compatibility with a variety of printers make it the ideal choice for businesses of all sizes. By choosing our Fpc Sticker, you can benefit from a labeling solution that offers flexibility, practicality, and environmental sustainability.

Unlocking the Potential: Exploring the Double Sided PCB Boards' Advancements

[Company Introduction]Located in the heart of the electronics industry, the pioneering company XYZ specializes in the manufacturing and development of Electronic Printed Circuit Boards (PCBs). With over 20 years of experience, XYZ has become a leading provider of high-quality PCB solutions, catering to a wide range of industries including telecommunications, automotive, medical, aerospace, and consumer electronics.XYZ has consistently excelled in innovation, investing a significant amount in research and development to ensure their PCBs are at the forefront of technological advancements. The company's commitment to quality, reliability, and customer satisfaction has earned them a solid reputation within the industry.[Double-Sided PCB Board Revolutionizes Electronics Manufacturing]XYZ recently unveiled its groundbreaking Double-Sided PCB Board, an innovation set to revolutionize the electronics manufacturing landscape. This new product is designed to address the growing demand for smaller, more efficient, and smarter electronic devices.Traditionally, single-sided PCBs have been widely used, providing a cost-effective solution for many applications. However, advancements in technology have led to an increased need for more complex circuitry in smaller devices, paving the way for double-sided PCBs in electronic manufacturing.Double-sided PCBs offer significant advantages over their single-sided counterparts. By utilizing both sides of the circuit board, these PCBs allow for an increased component density, thereby optimizing the available space on the board. This enables manufacturers to design smaller devices, making them more compact and portable without compromising on performance.One of the key features of double-sided PCBs is the ability to create more intricate and sophisticated circuits. With a double-sided board, manufacturers can incorporate more complex functionalities, such as wireless connectivity, sensor integration, and advanced power management systems. Additionally, double-sided PCBs provide enhanced signal quality and reduced electromagnetic interference, leading to improved overall device performance.The manufacturing process for double-sided PCBs involves the deposition of a conductive material on each side of the substrate, followed by the placement and attachment of components onto both sides. This intricate process requires advanced manufacturing capabilities, precision, and expertise to ensure the robustness and quality of the final product.XYZ has invested heavily in state-of-the-art manufacturing equipment, allowing them to produce double-sided PCBs with unparalleled precision and reliability. The company employs a team of highly skilled engineers and technicians who are constantly pushing the boundaries of double-sided PCB technology, ensuring that XYZ remains at the forefront of the industry.The launch of XYZ's double-sided PCBs has sparked excitement among electronics manufacturers and designers worldwide. The new product not only enables the development of smaller, more powerful devices, but also opens up endless possibilities for innovation in various industries. From wearable technology to smart home devices, double-sided PCBs have the potential to transform the way we interact with technology.With their commitment to quality, innovation, and customer satisfaction, XYZ continues to push the boundaries of what is possible in the electronics manufacturing industry. As the demand for smaller, more efficient devices increases, XYZ's double-sided PCBs are set to play a vital role in shaping the future of electronics.