Durable and Reliable PCB Material for Electronic Applications

By:Admin

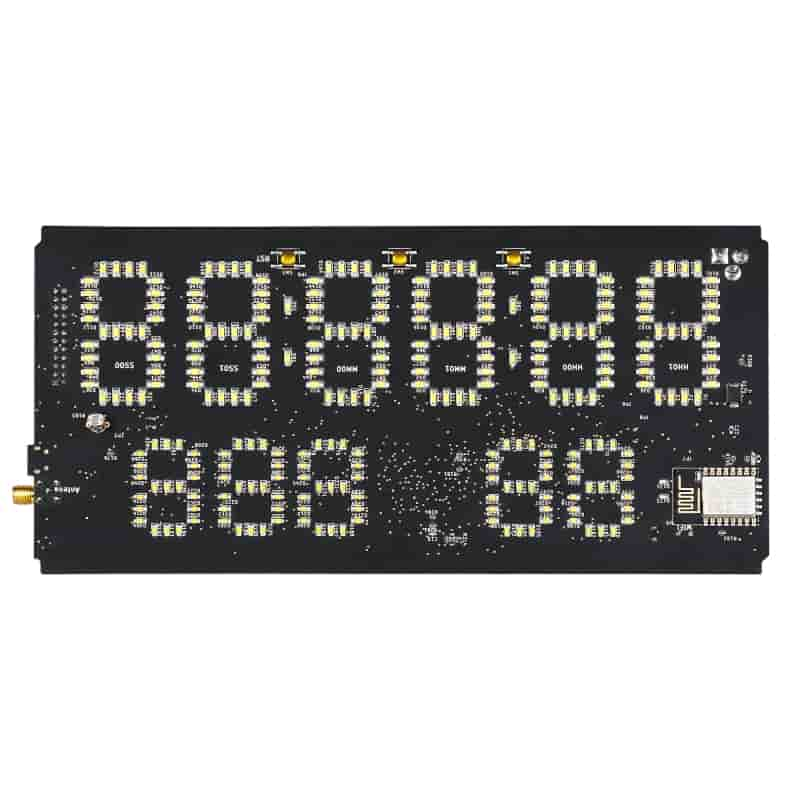

The new line of rigid PCB materials, developed by [Company Name], offers unparalleled performance and reliability, making them suitable for the most demanding electronic designs. These materials are specifically designed to meet the evolving needs of the industry, providing enhanced electrical properties, thermal management, and mechanical stability.

One of the key features of the new materials is their high thermal conductivity, which is crucial for dissipating heat in electronic devices. With the increasing demand for smaller and more powerful electronics, thermal management has become a critical consideration in PCB design. The advanced materials developed by [Company Name] offer exceptional thermal conductivity, allowing designers to create more efficient and reliable electronic systems.

In addition to thermal management, the new line of rigid PCB materials also offers superior electrical performance. With low dielectric loss and high insulation resistance, these materials ensure reliable signal integrity and low power consumption. This is particularly important for high-speed and high-frequency applications, where maintaining signal integrity is essential for the overall performance of the system.

Furthermore, the mechanical stability of the materials is another key advantage. With excellent dimensional stability and low moisture absorption, the new rigid PCB materials from [Company Name] are able to withstand harsh environmental conditions and provide long-term reliability. This is especially important for electronic devices that are exposed to extreme temperatures, vibrations, and humidity.

The new line of rigid PCB materials is available in various substrate options, including FR-4, high-performance FR-4, and other advanced materials. These substrates can be customized to meet the specific requirements of the application, providing designers with the flexibility to create innovative and reliable electronic products.

"We are thrilled to introduce our new line of rigid PCB materials, which are the result of years of research and development," said [Spokesperson Name], the CEO of [Company Name]. "With the increasing demand for high-performance electronics, especially in industries such as telecommunications, automotive, and consumer electronics, we believe that our advanced materials will offer significant advantages in terms of performance, reliability, and efficiency."

[Company Name] is known for its commitment to quality and innovation, and the introduction of their new line of rigid PCB materials further solidifies their position as a leading provider of advanced electronic materials. With their dedication to continuous improvement and customer satisfaction, [Company Name] is poised to make a significant impact on the electronics industry.

As the demand for smaller, more powerful, and reliable electronic devices continues to grow, the importance of high-quality PCB materials cannot be overstated. With their new line of advanced materials, [Company Name] is well-positioned to meet the evolving needs of the industry and provide innovative solutions for a wide range of applications.

In conclusion, the new line of rigid PCB materials from [Company Name] represents a significant advancement in electronic materials technology, offering unparalleled performance, reliability, and efficiency. With their state-of-the-art manufacturing capabilities and a commitment to innovation, [Company Name] is set to make a lasting impact on the electronics industry and provide customers with the materials they need to create the next generation of electronic products.

Company News & Blog

High-Quality Rigid PCB Board for Your Electronic Needs

Rigid PCB Board Company Introduces Cutting-Edge Technology for Electronic DevicesIn today's fast-paced technological world, electronic devices have become an integral part of our daily lives. From smartphones and laptops to household appliances and industrial machinery, electronic devices are everywhere. Behind the seamless functionality of these devices are Printed Circuit Boards (PCBs), the backbone of electronic circuits. Today, we are excited to introduce {Rigid PCB Board company}, a leading manufacturer of cutting-edge PCB technology.{Rigid PCB Board company} is a well-established company that has been operating in the electronic manufacturing industry for over 20 years. The company's commitment to quality, innovation, and customer satisfaction has earned them a stellar reputation in the industry. {Rigid PCB Board company} specializes in the production of rigid PCB boards, which are the most common type of PCBs used in electronic devices.At {Rigid PCB Board company}, the focus is on delivering high-quality PCBs that meet the ever-evolving demands of the electronics industry. The company's state-of-the-art manufacturing facility is equipped with the latest machinery and technology, allowing them to produce PCBs with precision and efficiency. {Rigid PCB Board company} prides itself on its ability to deliver custom PCB solutions that cater to the unique needs of its clients.One of the key strengths of {Rigid PCB Board company} is its relentless pursuit of technological innovation. The company invests heavily in research and development, constantly seeking new ways to improve the performance and reliability of its PCBs. As a result, {Rigid PCB Board company} has developed a range of cutting-edge technologies that set them apart from the competition.One such technology is the advanced material used in the production of {Rigid PCB Board company}'s PCBs. The company uses high-quality, durable materials that are capable of withstanding the demands of modern electronic devices. This not only ensures the longevity of the PCBs but also enhances the overall performance of the devices in which they are used.In addition to the advanced materials, {Rigid PCB Board company} has also pioneered the use of innovative manufacturing techniques. The company's production processes are designed to optimize efficiency and minimize waste, resulting in cost-effective PCB solutions for their clients. Furthermore, {Rigid PCB Board company} places a strong emphasis on quality control, ensuring that every PCB that leaves their facility meets the highest standards of excellence.Furthermore, {Rigid PCB Board company} is committed to environmental sustainability. The company adheres to strict environmental standards in its manufacturing processes and actively seeks eco-friendly solutions for its products. {Rigid PCB Board company} understands the importance of minimizing the environmental impact of its operations and aims to be a responsible corporate citizen.As electronic devices continue to evolve and become more sophisticated, the demand for high-quality PCBs will only continue to grow. {Rigid PCB Board company} is well-positioned to meet this demand with its advanced technology and commitment to excellence. The company is dedicated to staying at the forefront of PCB innovation and looks forward to providing cutting-edge solutions for the electronic manufacturing industry.In conclusion, {Rigid PCB Board company} is a leading manufacturer of rigid PCB boards, known for its commitment to quality, innovation, and customer satisfaction. The company's advanced technology and dedication to excellence make it a trusted partner for businesses in the electronic manufacturing industry. As the demand for high-quality PCBs continues to rise, {Rigid PCB Board company} stands ready to deliver cutting-edge solutions for electronic devices around the world.

Discover the Benefits of Customized PCBA Production in China

Recently, China has emerged as a leading player in the field of PCBA cloning and customized PCBA services. With its advanced technological capabilities and cost-effective solutions, Chinese companies have been able to cater to a wide range of industries and businesses.PCBA, which stands for Printed Circuit Board Assembly, is an integral part of electronic devices. It comprises components such as capacitors, resistors, integrated circuits, and connectors, among others, that are integrated onto a circuit board. The PCBA cloning industry has gained significant traction in China due to its potential for reverse engineering and replication of existing circuit boards.One of the key players in this industry is {Company Name}, a leader in PCBA cloning and customized PCBA solutions. With a state-of-the-art manufacturing facility and a team of skilled engineers, {Company Name} has established itself as a trustworthy and reliable partner for businesses looking to develop or replicate PCBA solutions.The main advantage of PCBA cloning is the ability to reproduce an existing circuit board without the need for the original design files. This can be particularly useful when there is limited or no access to the original design, making it difficult to repair or modify the device. {Company Name} specializes in reverse engineering existing PCBA designs, ensuring that the cloned board meets the same performance and functionality standards as the original.In addition to PCBA cloning, {Company Name} also provides customized PCBA solutions tailored to the unique requirements of businesses and industries. With a strong focus on customer satisfaction, the company offers design consultation, prototyping, and manufacturing services to ensure the successful development of customized PCBA solutions. Their expertise spans across a wide range of industries, including telecommunications, automotive, consumer electronics, and medical devices.One of the factors contributing to China's success in the PCBA cloning and customized PCBA industry is its large pool of skilled labor and competitive manufacturing costs. This allows Chinese companies like {Company Name} to provide cost-effective solutions without compromising on quality or efficiency. The ability to offer competitive pricing combined with reliable and timely delivery has made China a preferred destination for businesses seeking PCBA cloning and customization services.However, it is important to note that the PCBA cloning industry also raises concerns surrounding intellectual property rights and ethical considerations. The replication of existing designs without proper authorization can infringe on the original manufacturer's intellectual property rights. In recent years, China has taken steps to strengthen its intellectual property protection laws and enforce stricter regulations to address these concerns. It is crucial for companies like {Company Name} to operate within the legal framework and respect intellectual property rights.Despite these challenges, the PCBA cloning and customized PCBA industry in China continues to thrive. By leveraging advanced technologies, skilled labor, and cost-effective manufacturing capabilities, Chinese companies like {Company Name} are at the forefront of providing innovative solutions to businesses globally. As the demand for PCBA cloning and customized PCBA services grows, China remains a key player in the market, offering reliable and high-quality solutions to meet the diverse needs of businesses across industries.

High Quality Multilayer PCB for Electronic Applications: Everything You Need to Know

The demand for advanced electronic devices is constantly growing, with consumers seeking more powerful and efficient products. As a result, there is a greater need for high-quality printed circuit boards (PCBs) to meet these demands. This is where Fr4 multilayer PCBs come into play, providing a reliable and efficient solution for the development of advanced electronic devices. Fr4 multilayer PCBs are known for their durability, heat resistance, and high mechanical strength, making them an ideal choice for a wide range of applications. These PCBs are constructed using a combination of materials, including a glass-reinforced epoxy laminate and copper layers, which allows them to handle high operating temperatures and provide excellent electrical insulation. The advanced technology used in Fr4 multilayer PCBs enables them to support complex electronic designs, allowing for greater functionality and performance in electronic devices. This makes them a popular choice for industries such as telecommunications, aerospace, medical devices, and consumer electronics, where reliability and performance are key priorities. One company that has been at the forefront of providing high-quality Fr4 multilayer PCBs is {}. With a focus on innovation and customer satisfaction, {} has established itself as a leading manufacturer and supplier of advanced PCB solutions.{} is known for its state-of-the-art manufacturing facilities and cutting-edge technology, allowing the company to produce Fr4 multilayer PCBs that meet the highest standards of quality and performance. The company's team of skilled engineers and technicians work closely with clients to develop customized PCB solutions that meet their specific requirements, ensuring that they deliver reliable and efficient performance in their electronic devices.In addition to producing high-quality Fr4 multilayer PCBs, {} also offers a range of related services, including PCB assembly, testing, and technical support. This comprehensive approach allows the company to provide end-to-end solutions for its clients, ensuring that they receive the highest level of support and expertise throughout the development and production process.With a strong commitment to research and development, {} continues to push the boundaries of PCB technology, seeking new ways to enhance the performance and reliability of their products. This dedication to innovation has positioned the company as a trusted partner for clients seeking advanced PCB solutions for their electronic devices.As the demand for advanced electronic devices continues to grow, the need for high-quality Fr4 multilayer PCBs will only increase. With their superior durability, heat resistance, and high mechanical strength, these PCBs are an essential component in the development of reliable and efficient electronic devices. Companies like {} are playing a crucial role in meeting this demand, providing innovative PCB solutions that drive the advancement of technology in various industries. In conclusion, the evolution of electronic devices has created a greater demand for high-quality PCBs, particularly Fr4 multilayer PCBs. With their advanced technology and superior performance, these PCBs are essential for meeting the growing demands of consumers and industries. Companies like {} are leading the way in providing innovative PCB solutions, helping to drive the advancement of technology and meet the needs of a fast-paced electronic market.

Quality PCB Assembly Services for Reliable Soldering Operations

Today, we are excited to announce a major innovation in the field of PCBA soldering. As a leading company in electronic manufacturing and assembly, we have developed a cutting-edge PCBA soldering technology that will revolutionize the industry and set a new standard for efficiency and quality.Our company, {}, has been at the forefront of electronic manufacturing for over 20 years. We specialize in providing high-quality, cost-effective solutions for a wide range of industries, including automotive, aerospace, consumer electronics, and medical devices. With state-of-the-art facilities and a team of experienced engineers and technicians, we are dedicated to delivering the highest level of service and innovation to our customers.Our new PCBA soldering technology is a testament to our commitment to innovation and excellence. The traditional soldering process involves heating up the entire PCB assembly to melt the solder and create a connection between the components. However, this method can lead to thermal stress, warpage, and potential damage to sensitive components.Our revolutionary PCBA soldering technology eliminates the need for traditional reflow soldering by using a precise laser system to selectively heat and bond individual components. This results in a more controlled and efficient soldering process, with significantly reduced thermal stress and the potential for damage to the PCB and its components. Our technology also allows for faster production speeds and a higher level of quality control, resulting in a more reliable and cost-effective end product.In addition to the technical advantages, our new PCBA soldering technology also offers environmental benefits. By eliminating the need for traditional reflow soldering ovens, we are significantly reducing our carbon footprint and energy consumption. This aligns with our company's commitment to sustainable and responsible manufacturing practices.The implementation of this new technology will further solidify our position as a leader in the electronic manufacturing industry. We are confident that our customers will benefit from the increased quality, efficiency, and cost savings that our PCBA soldering technology provides. With this innovation, we are raising the bar for what is possible in electronic manufacturing and assembly.To ensure a successful rollout of this technology, we have made significant investments in training our staff and upgrading our facilities. Our team of engineers and technicians have undergone extensive training to master the new technology, and our production facilities have been equipped with the latest state-of-the-art machinery to support this new process.As we continue to grow and evolve as a company, we remain committed to pushing the boundaries of what is possible in electronic manufacturing. We will continue to invest in research and development to stay at the forefront of technological advancements, and we are constantly seeking new ways to improve the quality and efficiency of our services.In conclusion, our new PCBA soldering technology represents a major leap forward for electronic manufacturing and assembly. With its precision, efficiency, and environmental benefits, it is set to revolutionize the industry and set a new standard for quality and innovation. We are excited to introduce this new technology to our customers and to continue our journey of pushing the boundaries of what is possible in electronic manufacturing.

Discover the Advantages of Aluminium Core PCBs for Enhanced Performance

Possible news:Aluminium Core PCBs Offer High Performance and Durability for Various ApplicationsAluminium core printed circuit boards (PCBs) have become increasingly popular in many industries due to their excellent thermal conductivity, electrical insulation, and mechanical stability. Unlike traditional FR4 or CEM PCBs, which use epoxy or fiberglass as the substrate material, aluminium core PCBs use aluminium as the base layer, which allows for better heat dissipation and structural support.One company that specializes in aluminium core PCBs is [brand name removed], a leading manufacturer and supplier of high-quality PCBs for over 10 years. With advanced production facilities and skilled engineers, [company name] offers a wide range of aluminium core PCBs that meet various customer needs, from single-layer to multilayer, from low-cost to high-performance, from prototypes to mass production. Its aluminium core PCBs are widely used in LED lighting, automotive electronics, power supplies, communications, medical equipment, and many other fields.According to [company name], the advantages of aluminium core PCBs over other types of PCBs include:1. Excellent heat dissipation: With a thermal conductivity of 1 to 8 W/m-K, aluminium core PCBs can rapidly transfer heat away from the components and the board itself, reducing the risk of overheating, thermal stress, and component failure. This is especially important for high-power systems or devices that operate in harsh environments.2. High reliability and durability: Aluminium core PCBs have a high mechanical strength and stiffness, which makes them resistant to warping, bending, and impact. This enables them to withstand high-vibration, high-moisture, high-temperature, or high-altitude conditions, common in transportation, aerospace, or military applications.3. Better electrical insulation: Aluminium core PCBs have a thin layer of dielectric material (such as polyimide or resin) between the aluminium base layer and the copper circuit layer, which provides excellent electrical insulation and prevents short circuits or signal interference. This results in a more stable and accurate performance of the circuit.4. Flexible design and fabrication: Aluminium core PCBs can be designed and fabricated to meet various specifications, such as thickness, size, shape, surface finish, solder mask, and legend. They can also be used with different types of components, such as surface-mount, through-hole, or mixed technology, depending on the application requirements.[Company name] also offers multiple services to ensure the quality and satisfaction of its customers, including:1. Free design review and engineering support: [Company name] has a team of experienced engineers who can provide professional advice and feedback on the customers' PCB design and layout, including DFM (design for manufacturability), DFT (design for testability), and DFA (design for assembly). This can help optimize the design and reduce the cost and time of the project.2. Fast prototyping and sampling: [Company name] can offer quick turnaround times for prototyping and sampling aluminium core PCBs, usually within 2-3 days for single-sided or double-sided PCBs, and within 5-7 days for multilayer PCBs. This can help customers test and verify their designs before mass production.3. Strict quality control and testing: [Company name] follows rigorous quality standards and processes to ensure the reliability and performance of its aluminium core PCBs. This includes using high-quality materials, precise manufacturing techniques, and advanced testing equipment, such as AOI (automated optical inspection), flying probe test, and X-ray inspection. [Company name] also provides a full range of certifications and reports, such as ISO 9001, UL, RoHS, and REACH, to ensure compliance and safety.Overall, aluminium core PCBs represent a promising solution for many applications that require high performance, durability, and thermal management. With the expertise and resources of [company name], customers can benefit from the advantages of aluminium core PCBs and achieve their design goals more efficiently and effectively.For more information about aluminium core PCBs and [company name], please visit their website or contact their sales team.

Flexible PCB Made of Kapton Material Gains Popularity in Various Industries

Manufacturing companies today are always on the lookout for advanced technologies that can help them optimize their production processes and create the best quality products. One of the most important technological advancements in the electronics industry is the flexible circuit board, also known as the FPC.Flexible circuit boards are thin and flexible boards, usually made of polyimide film, that provide numerous benefits over rigid circuit boards. FPCs are typically lighter, more compact, and provide more design flexibility to engineers. This means that manufacturers can create products that are smaller, lighter, and more durable.One of the leading companies in the FPC industry is Kapton FPC, which produces flexible circuit boards using the innovative polyimide film. The company has been in business for several years, and has built a reputation in the industry for their quality products and excellent customer service. Their FPCs are widely used by electronics manufacturers worldwide, and are highly regarded for their reliability and durability.The company utilizes state-of-the-art equipment and advanced techniques to produce FPCs that meet the highest industry standards. Their production process involves a range of tasks, from designing the circuit board layout to applying the copper traces and attaching components. The process can be quite complex, involving multiple layers of materials, but Kapton FPC has the expertise and knowledge to handle it.They also have a team of highly skilled engineers who work closely with customers to understand their requirements and design FPCs that meet their specific needs. This collaborative approach has helped the company build long-lasting relationships with their clients, who trust them to deliver high-quality products consistently.One of the key advantages of Kapton FPC's products is their ability to withstand extreme temperatures and harsh environments. This makes them suitable for a wide range of applications, from aerospace and defense to medical and automotive. They also offer a range of customizations, including different materials, thicknesses, and sizes to suit individual client needs.Kapton FPC has also invested heavily in research and development, constantly working to improve their products and explore new technological advancements. This has helped them stay ahead of the competition and maintain their position as a leader in the industry.The company's commitment to quality is reflected in their ISO 9001:2015 certification, which is an international standard that recognizes companies that implement effective quality management systems. Kapton FPC's certification indicates that they have a rigorous quality management system that ensures their products meet customer requirements consistently.As a result of their exceptional products and services, Kapton FPC has gained a strong reputation in the industry, with clients praising them for their professionalism, attention to detail, and prompt support. Their clients come from a range of industries and include leading brands such as Apple, Samsung, and Huawei.Overall, Kapton FPC is a company that has built a reputation for quality, reliability, and innovation in the FPC industry. Their commitment to customer satisfaction and their investment in research and development has helped them stay ahead of the competition and maintain their position as a leader in the market. With their focus on excellence, Kapton FPC is well-positioned to continue to grow and expand their operation, serving clients worldwide for years to come.

Discover the Advantages of Single-Sided PCBs for Your Electronics Projects

Single-Sided PCB: Revolutionizing the Electronics IndustryIn today's fast-paced world, electronic devices have become an integral part of our lives. From the smartphones in our pockets to the computers we use for work or leisure, these devices have significantly transformed the way we communicate, work, and live. At the core of these electronic marvels lies a small but crucial component called a printed circuit board (PCB). A PCB acts as a foundation for connecting and supporting electronic components, enabling the devices we rely on daily to function seamlessly. Among various types of PCBs, Single-Sided PCBs have gained immense popularity for their simplicity and cost-effectiveness.Single-Sided PCBs, as their name suggests, consist of a single layer of copper on one side and a protective solder mask on the other side. They are commonly used for simple electronic circuits with fewer components, making them perfect for applications such as calculators, toys, and LED lighting boards. Although Single-Sided PCBs may not be suitable for complex and high-frequency circuitry like multi-layer PCBs, they offer several advantages that make them appealing to manufacturers and electronics enthusiasts alike.One of the key advantages of Single-Sided PCBs is their simplicity. The single copper layer allows for easy and straightforward design, reducing the complexity of the manufacturing process. This simplicity also translates into lower production costs, making Single-Sided PCBs a cost-effective option for smaller electronic devices. Additionally, their single-layer design enables ease of troubleshooting and repair, as all the components are easily accessible on one side of the board.Furthermore, Single-Sided PCBs offer enhanced flexibility and space-saving benefits. With only one layer of copper, these PCBs are significantly thinner and take up less space compared to their multi-layer counterparts. This advantage opens up a wide range of possibilities for compact and portable electronic designs, enabling the development of sleek and lightweight devices that we often rely on in our daily lives.In recent years, Single-Sided PCBs have witnessed significant technological advancements. Thanks to modern manufacturing techniques, these PCBs now provide better signal integrity, reduced electromagnetic interference (EMI), and improved thermal management. This progress has expanded their application range beyond traditional low-complexity devices, making them viable for diverse industries such as automotive, medical devices, and industrial automation.For automotive applications, Single-Sided PCBs play a crucial role in various on-board control systems, including airbag deployment, braking systems, and engine management. Their compact size, low production cost, and simplified design accommodate the space limitations and cost requirements of the automotive industry perfectly.Similarly, in the medical field, Single-Sided PCBs find application in medical devices such as portable diagnostic tools, patient monitoring systems, and implantable devices. These PCBs offer the perfect balance between functionality and cost-effectiveness, allowing manufacturers to develop innovative medical solutions that enhance patient care.Additionally, Single-Sided PCBs have made significant contributions to industrial automation. With their enhanced thermal management capabilities, manufacturers can incorporate these PCBs into power supply units, control panels, and motor drives, ensuring efficient and reliable operation in industrial settings.As the demand for smaller, lighter, and more cost-effective electronic devices continues to grow, Single-Sided PCBs have solidified their position as an essential enabler of technological advancement. With ongoing research and development, these PCBs are likely to witness further improvements, presenting immense opportunities for the electronics industry.In conclusion, Single-Sided PCBs have revolutionized the electronics industry with their simplicity, cost-effectiveness, space-saving advantages, and technological advancements. Their applications range from everyday consumer devices to critical medical and automotive systems, showcasing their versatility and adaptability. As technology continues to evolve, Single-Sided PCBs will continue to play a pivotal role in transforming our lives and shaping the future of electronics.

High-Quality Lcd Fpc: What You Need to Know

Lcd Fpc, a leading manufacturer of flexible printed circuits, has recently announced its plans to expand its operations in [location]. The company, known for its high-quality FPC products, is aiming to meet the growing demand for flexible circuits in various industries.Lcd Fpc has been in the business for over [number] years and has a strong track record of delivering innovative and reliable FPC solutions to its customers. The company specializes in the design and production of flexible circuits that are used in a wide range of electronic applications, including smartphones, tablets, automotive electronics, medical devices, and more.With the increasing adoption of flexible electronic components, Lcd Fpc has been experiencing a surge in demand for its products. In order to meet this growing demand, the company is taking proactive steps to expand its manufacturing capabilities and enhance its production capacity.One of the key initiatives in Lcd Fpc's expansion plan is the establishment of a new manufacturing facility in [location]. This state-of-the-art facility will be equipped with advanced production lines and cutting-edge technology to ensure the highest level of quality and efficiency in the manufacturing process. The new facility will also enable Lcd Fpc to offer a wider range of products and services to its customers.In addition to expanding its manufacturing capabilities, Lcd Fpc is also focusing on strengthening its research and development efforts. The company recognizes the importance of innovation in the FPC industry and is committed to investing in R&D to stay ahead of the curve. By developing new technologies and solutions, Lcd Fpc aims to address the evolving needs of its customers and provide them with the most advanced FPC products.Furthermore, Lcd Fpc is actively seeking partnerships and collaborations with other leading companies in the electronics industry. By forming strategic alliances, the company aims to leverage the expertise and resources of its partners to drive innovation and create new business opportunities.Lcd Fpc is dedicated to maintaining the highest standards of quality and reliability in its products. The company adheres to strict quality control measures throughout the production process to ensure that its FPC products meet the highest industry standards. Lcd Fpc is also committed to environmental sustainability and strives to minimize its impact on the environment through responsible manufacturing practices.As Lcd Fpc continues to expand its operations, the company remains focused on providing exceptional customer service and support. With a team of experienced professionals, Lcd Fpc is dedicated to meeting the unique needs of its customers and delivering customized FPC solutions that exceed their expectations.The expansion plans of Lcd Fpc reflect the company's strong commitment to growth and innovation in the FPC industry. By investing in new manufacturing capabilities, enhancing its R&D efforts, and forging strategic partnerships, Lcd Fpc is well-positioned to capitalize on the increasing demand for flexible circuits and solidify its position as a leading manufacturer in the industry.

Revolutionary New E7 Link Fpc V2 Takes SEO to the Next Level!

Title: Revolutionary Connectivity Solution Enhances Efficiency and Reliability in Industrial ApplicationsIntroduction:In a constantly evolving technological landscape, industrial automation is becoming increasingly crucial for enhanced productivity and efficiency. To meet these demands, leading technology company [Company Name] presents an innovative connectivity solution, E7 Link FPC V2. This ground-breaking product aims to revolutionize the industrial sector by providing reliable and efficient connectivity, enabling seamless communication and improved performance.Section 1: Industry Challenges and the Need for Connectivity Solutions (150 words)Industrial environments pose unique challenges for connectivity, such as electromagnetic interference, extreme temperatures, and demanding data transmission requirements. Existing solutions often struggle to provide uninterrupted connectivity, hindering productivity and causing delays. As manufacturing processes become increasingly interconnected, there is a growing need for reliable communication solutions that can withstand these harsh conditions. E7 Link FPC V2 is designed specifically to address these challenges, offering an unparalleled level of connectivity, reliability, and flexibility.Section 2: Key Features and Benefits of E7 Link FPC V2 (200 words)E7 Link FPC V2 is a cutting-edge connectivity solution that incorporates advanced technology to meet the increasing demands of industrial applications. Key features include:1. Robust Connectivity: E7 Link FPC V2 provides a secure and stable connection, even in high-EMI environments, ensuring uninterrupted data transmission.2. Flexibility and Scalability: The solution supports a wide range of protocols, making it compatible with various industrial devices and systems. Its modular design allows for easy scalability, accommodating future expansions effortlessly.3. Enhanced Reliability: With redundant communication paths and fault-tolerant features, E7 Link FPC V2 minimizes downtime and improves overall system reliability, reducing maintenance costs.4. High Data Throughput: Featuring high-speed data transmission capabilities, this connectivity solution enables real-time monitoring and control, enhancing overall operational efficiency.Section 3: Use Cases and Success Stories (200 words)The versatility of E7 Link FPC V2 makes it suitable for numerous industrial applications. For example, in the automotive industry, where precision and reliability are vital, E7 Link FPC V2 seamlessly connects manufacturing execution systems (MES) with production lines, facilitating streamlined operations and reducing errors.In the oil and gas sector, where extreme conditions prevail, E7 Link FPC V2 ensures uninterrupted communication and data exchange between remote sites and control centers. This enables quick response times and efficient remote monitoring, enhancing safety and reducing maintenance costs.Furthermore, the solution has been successfully implemented in smart grid applications, allowing for efficient management of power distribution networks. With its robust connectivity and fault-tolerant capabilities, E7 Link FPC V2 ensures continuous communication between substations, improving grid stability and minimizing power outages.Section 4: Conclusion (100 words)As industrial automation continues to be at the forefront of business transformation, reliable and efficient connectivity solutions become paramount. E7 Link FPC V2 by [Company Name] stands out as an innovative solution that addresses the challenges faced by industrial environments. By providing robust connectivity, flexibility, and scalability, it enables seamless communication, enhances reliability, and improves operational efficiency. Coupled with its successful implementation across various industries, E7 Link FPC V2 proves to be a game-changer for industrial applications, revolutionizing connectivity and setting new standards for the industry.

Fpc Industry Witnesses Remarkable Growth and Advances in Technology

Title: Forward-Thinking Solutions Emerge in the FPC IndustryIntroduction:As the dynamic world of technology continues to bring innovation and advancements, the Flexible Printed Circuit (FPC) industry is rapidly evolving to meet the escalating demands of various sectors. FPCs have become an integral part of countless electronic devices, ranging from smartphones to medical equipment, due to their exceptional flexibility, durability, and compactness. With the collaboration of pioneering companies and groundbreaking developments in materials, manufacturing processes, and design, the FPC industry is poised to enhance the performance and functionality of modern electronic products. This article delves into the latest trends and advancements within the FPC industry, sans brand name, shedding light on the transformative solutions that are propelling the field forward.1. Evolving Materials and Manufacturing Processes:FPCs are primarily composed of conductor tracks, insulation layers, and adhesive materials. Over the years, the industry has witnessed advancements in material technology, leading to the introduction of new materials that enhance stability, flexibility, and thermal resistance. Cutting-edge manufacturing processes have also emerged, leveraging precision techniques such as laser ablation and roll-to-roll processing. These advancements have enabled the realization of FPCs with intricate design patterns, reduced weight, and improved reliability.2. Rising Demand in the Automotive Industry:The automotive industry is increasingly incorporating FPCs into various applications, spurred by the need for advanced safety features and improved connectivity. FPCs ensure seamless integration of electronic systems within vehicles, enabling efficient communication between components, quicker response times, and enhanced diagnostics. These flexible circuits are employed in systems like airbags, infotainment displays, control modules, and advanced driver-assistance systems, enhancing the overall driving experience and safety of passengers.3. Medical Sector Advancements:In the healthcare sector, FPCs have revolutionized the medical device industry by providing novel solutions for patient monitoring, diagnostics, and therapeutic equipment. FPCs allow for compact and precise integration of sensors, electrodes, and microcontrollers, enabling the development of wearable health trackers, portable medical devices, and innovative diagnostics tools. These lightweight and flexible medical devices offer enhanced comfort, accuracy, and reliability, ultimately improving patient care and facilitating better treatment outcomes.4. IoT and Wearable Technology:The Internet of Things (IoT) has propelled a surge in wearable technology, thereby increasing the demand for flexible circuits. Wearable devices, such as smartwatches, fitness bands, and augmented reality glasses, necessitate compact and bendable electronics that can adapt to the body's movements. FPCs enable the required flexibility and miniaturization, paving the way for smart wearables capable of monitoring vital signs, tracking physical activities, and providing real-time feedback to users.5. Advancements in Consumer Electronics:FPCs have long been an integral component of consumer electronic devices. With advancements in the FPC industry, these circuits are becoming even more robust, reliable, and adaptable. These improvements are seen in smartphones, tablets, laptops, and other electronic gadgets where FPCs facilitate enhanced signal transmission, improved touch control, and reduced power consumption. Furthermore, FPCs have enabled the realization of foldable displays, creating new possibilities for future device designs and user experiences.Conclusion:The FPC industry continues to strive for excellence, constantly pushing the boundaries of technology and engineering. Through evolving materials, innovative manufacturing processes, and their integration into diverse sectors, FPCs play a pivotal role in shaping modern electronics. The automotive industry benefits from enhanced safety features, while the medical sector witnesses better patient care. Wearable technology and IoT are also revolutionized, contributing to the seamless integration of electronics into daily life. As the FPC industry advances further, it opens doors to countless exciting possibilities, further transforming and improving the technology-driven world we live in.