Pioneering Advances in PCB Manufacturing and Assembly Techniques Revealed!

By:Admin

Introduction:

In today's fast-paced technological world, Printed Circuit Boards (PCBs) have become an integral part of every electronic device, from smartphones to complex industrial machinery. As demand for efficient, reliable, and high-quality PCBs continues to grow, there is an increasing need for advanced manufacturing and assembly solutions. In this news article, we explore the evolving landscape of PCB manufacturing and assembly, with a particular focus on one leading company that excels in this domain.

PCB Manufacturing and Assembly: Meeting the Growing Demands of the Industry

The global PCB market is witnessing remarkable growth, driven by emerging technologies such as the Internet of Things (IoT), 5G, electric vehicles, and artificial intelligence. These advancements require PCBs to be smaller, more complex, and capable of handling higher power densities. As a result, the need for specialized PCB manufacturing and assembly services has become crucial to sustain innovation and meet market demands.

Removing Brand Name: A Leader in Advanced PCB Manufacturing and Assembly

One prominent player at the forefront of PCB manufacturing and assembly is {} (brand name removed). With years of industry experience, state-of-the-art facilities, and a customer-focused approach, they have established themselves as a trusted partner for numerous companies across various sectors.

Capabilities and Offerings:

{Company Name} offers an extensive range of services, covering the entire PCB manufacturing and assembly process. Their capabilities include:

1. Design Support: Their team of highly skilled engineers works closely with clients to optimize PCB designs for functionality, manufacturability, and cost-effectiveness. By leveraging advanced software and simulation tools, they ensure that each design meets the highest industry standards.

2. Prototyping: With a strong emphasis on rapid prototyping, {} enables clients to quickly validate their PCB designs before moving ahead with large-scale production. This iterative process helps identify and address any potential challenges, reducing time-to-market for innovative products.

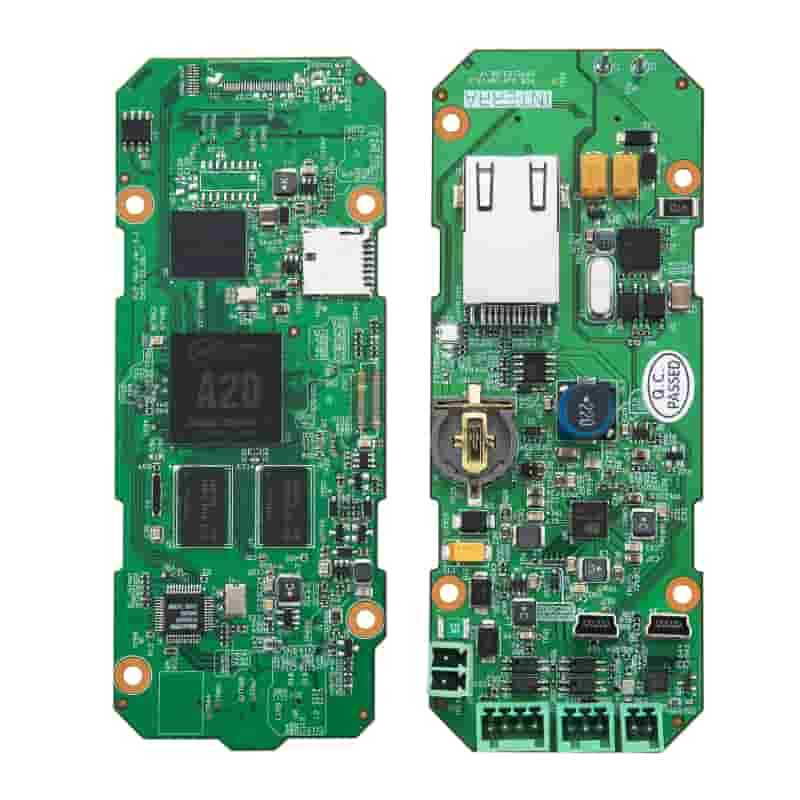

3. Manufacturing: {} (brand name removed) utilizes cutting-edge manufacturing equipment and process controls to deliver high-quality PCBs. Advanced techniques such as surface-mount technology (SMT), through-hole technology (THT), and multilayer PCB manufacturing enable them to meet the diverse needs of their clients.

4. Assembly: Their expertise in PCB assembly allows them to handle complex component placements, high-density interconnections, and stringent quality controls. They utilize automated assembly lines, ensuring accuracy, consistency, and scalability while adhering to international standards.

Quality Assurance and Certifications:

Quality is of paramount importance in the PCB industry. {} upholds stringent quality control measures at every stage of manufacturing and assembly. Their commitment to excellence is reflected in various certifications they have obtained, such as ISO 9001 and UL certifications. These certifications ensure that their operations are in compliance with industry regulations and that their products meet the highest quality standards.

Meeting Market Demands:

{} (brand name removed) understands the market demand for shorter lead times, cost-effective solutions, and advanced PCB technologies. Therefore, they continually invest in research and development to stay ahead of the curve. By incorporating the latest materials, processes, and automation techniques, they can meet the evolving needs of industries such as telecommunications, automotive, consumer electronics, and industrial automation.

Conclusion:

The progressive demands of the technology-driven world necessitate reliable and innovative PCB manufacturing and assembly solutions. {} (brand name removed) has emerged as a leader in this domain, offering comprehensive capabilities, exceptional quality standards, and customer-centric services. Through their commitment to excellence, they empower companies across industries to bring their cutting-edge products to market efficiently and reliably.

Company News & Blog

Optimizing PCB Board Connections for Improved Performance: A Comprehensive Guide

Title: PCB Board Connection Company Revolutionizes Electronics Industry with Cutting-Edge SolutionsIntroduction:[Company Name], a leading player in the electronics industry, is making waves with its groundbreaking PCB board connection solutions. The company, headquartered in [Location], has consistently demonstrated its commitment to innovation and customer satisfaction, setting new standards for the industry. With a diverse range of state-of-the-art products and a team of highly skilled professionals, [Company Name] has truly revolutionized the way electronic devices are designed and manufactured.Content:1. The Emergence of [Company Name] in the Electronics Industry (100 words)Since its inception, [Company Name] has placed greater emphasis on research and development, aiming to provide customized solutions to meet the needs of its diverse clientele. By combining cutting-edge technology with an efficient manufacturing process, the company has garnered recognition for its reliability and high-quality products. [Company Name]'s commitment to delivering exceptional customer service has earned it a solid reputation in the market, positioning the company as a leading provider of PCB board connection solutions.2. Groundbreaking PCB Board Connection Solutions (150 words)[Company Name] offers a wide range of innovative and reliable PCB board connection solutions that cater to different industries and applications. The company has invested heavily in advanced machinery and equipment to ensure the highest product standards. Its extensive product portfolio includes high-density interconnect (HDI) PCBs, flexible printed circuit boards (FPCBs), rigid-flex PCBs, and more. These solutions are built to withstand harsh environments, ensuring the long-term functionality and durability of electronic devices.3. State-of-the-Art Technology and Manufacturing Process (150 words)[Company Name] maintains a state-of-the-art manufacturing facility equipped with advanced automation, precision drilling, and assembly systems. Through its innovative technological advancements, the company has significantly reduced production time while ensuring exceptional quality control. By employing automated inspection, thorough testing procedures, and adherence to rigorous industry standards, [Company Name] guarantees reliability and consistency in every product delivered to its customers.4. Commitment to Sustainability (100 words)In addition to its technological advancements, [Company Name] places great importance on sustainability. The company adheres to eco-friendly practices throughout its manufacturing processes, minimizing waste generation and reducing its environmental footprint. By actively promoting the use of recyclable materials and investing in efficient energy management systems, [Company Name] not only contributes to a greener future but also sets an example for the industry as a whole.5. [Company Name]'s Competitive Edge and Market Positioning (150 words)[Company Name] holds a competitive edge in the market due to its ability to offer comprehensive solutions tailored to the specific requirements of its customers. Its team of highly skilled engineers and technicians works closely with clients to understand their needs and provide customized solutions. By focusing on persona-specific service and relentlessly pursuing research and development, [Company Name] has built long-lasting partnerships with leading companies across various industries. Moreover, its commitment to continuous improvement ensures that the company stays at the forefront of technological innovation.Conclusion:With its dedication to groundbreaking technology, exceptional manufacturing processes, and unwavering commitment to sustainability, [Company Name] has cemented its position as a leading player in the electronics industry. The company's ability to deliver customized PCB board connection solutions that exceed industry standards has consistently propelled its growth and success. By revolutionizing the electronics industry, [Company Name] continues to reshape the landscape by enabling technology to thrive in an increasingly interconnected world.

Revolutionary New E7 Link Fpc V2 Takes SEO to the Next Level!

Title: Revolutionary Connectivity Solution Enhances Efficiency and Reliability in Industrial ApplicationsIntroduction:In a constantly evolving technological landscape, industrial automation is becoming increasingly crucial for enhanced productivity and efficiency. To meet these demands, leading technology company [Company Name] presents an innovative connectivity solution, E7 Link FPC V2. This ground-breaking product aims to revolutionize the industrial sector by providing reliable and efficient connectivity, enabling seamless communication and improved performance.Section 1: Industry Challenges and the Need for Connectivity Solutions (150 words)Industrial environments pose unique challenges for connectivity, such as electromagnetic interference, extreme temperatures, and demanding data transmission requirements. Existing solutions often struggle to provide uninterrupted connectivity, hindering productivity and causing delays. As manufacturing processes become increasingly interconnected, there is a growing need for reliable communication solutions that can withstand these harsh conditions. E7 Link FPC V2 is designed specifically to address these challenges, offering an unparalleled level of connectivity, reliability, and flexibility.Section 2: Key Features and Benefits of E7 Link FPC V2 (200 words)E7 Link FPC V2 is a cutting-edge connectivity solution that incorporates advanced technology to meet the increasing demands of industrial applications. Key features include:1. Robust Connectivity: E7 Link FPC V2 provides a secure and stable connection, even in high-EMI environments, ensuring uninterrupted data transmission.2. Flexibility and Scalability: The solution supports a wide range of protocols, making it compatible with various industrial devices and systems. Its modular design allows for easy scalability, accommodating future expansions effortlessly.3. Enhanced Reliability: With redundant communication paths and fault-tolerant features, E7 Link FPC V2 minimizes downtime and improves overall system reliability, reducing maintenance costs.4. High Data Throughput: Featuring high-speed data transmission capabilities, this connectivity solution enables real-time monitoring and control, enhancing overall operational efficiency.Section 3: Use Cases and Success Stories (200 words)The versatility of E7 Link FPC V2 makes it suitable for numerous industrial applications. For example, in the automotive industry, where precision and reliability are vital, E7 Link FPC V2 seamlessly connects manufacturing execution systems (MES) with production lines, facilitating streamlined operations and reducing errors.In the oil and gas sector, where extreme conditions prevail, E7 Link FPC V2 ensures uninterrupted communication and data exchange between remote sites and control centers. This enables quick response times and efficient remote monitoring, enhancing safety and reducing maintenance costs.Furthermore, the solution has been successfully implemented in smart grid applications, allowing for efficient management of power distribution networks. With its robust connectivity and fault-tolerant capabilities, E7 Link FPC V2 ensures continuous communication between substations, improving grid stability and minimizing power outages.Section 4: Conclusion (100 words)As industrial automation continues to be at the forefront of business transformation, reliable and efficient connectivity solutions become paramount. E7 Link FPC V2 by [Company Name] stands out as an innovative solution that addresses the challenges faced by industrial environments. By providing robust connectivity, flexibility, and scalability, it enables seamless communication, enhances reliability, and improves operational efficiency. Coupled with its successful implementation across various industries, E7 Link FPC V2 proves to be a game-changer for industrial applications, revolutionizing connectivity and setting new standards for the industry.

Exciting Innovations in Flexible Printed Circuit (FPC) Technology Discovered

[Company Name] Introduces Revolutionary Flexible Printed Circuit Technology[date][City, State] - [Company Name], a global leader in advanced electronic solutions, has recently launched its groundbreaking FFC and FPC technology, aiming to reshape the electronics industry with its flexible and customizable circuitry. By eliminating the need for rigid circuit boards, [Company Name] offers a wide range of applications for industries such as consumer electronics, automotive, healthcare, and more.Flexible Printed Circuits (FPC) and Flat Flexible Cables (FFC) are key components in the development of sophisticated electronic devices. However, traditional FFC and FPC technologies have been limited by their rigid nature, which restricted designers' creativity and flexibility. With the introduction of [Company Name]'s innovative technology, a new era of electronics is just around the corner.The newly developed FFC and FPC technology by [Company Name] allows for the seamless integration of circuits onto flexible materials. This breakthrough brings unprecedented design possibilities, enabling the creation of bendable and foldable devices. From wearable technology to foldable smartphones, the applications of this technology are virtually endless.[Company Name] is confident that its FFC and FPC technology will greatly enhance various industries. One of the revolutionary features of this technology is its ability to withstand extreme physical stresses and accommodate dynamic movements, making it ideal for applications in the automotive industry. By introducing flexible circuitry into vehicles, [Company Name] envisions safer and more efficient control systems.Moreover, the healthcare industry will greatly benefit from [Company Name]'s FFC and FPC technology. Traditional medical devices, such as external monitors and implantable devices, often have rigid circuits that can cause discomfort or limitations for patients. With the integration of flexible circuitry, these devices can become more user-friendly, adaptable, and even comfortable for patients.[Company Name]'s commitment to innovation reflects in its extensive research and development efforts. The company has invested heavily in cutting-edge manufacturing techniques and materials, resulting in a robust and reliable flexible printed circuit technology. With a keen focus on quality, [Company Name] ensures that its products meet the highest industry standards and perform flawlessly in demanding environments.In addition to its technological advancements, [Company Name] also emphasizes its commitment to sustainability. Flexible printed circuits contribute to reducing electronic waste by eliminating the need for bulky rigid boards. The flexibility and customizability of [Company Name]'s technology also enable the development of thinner and more lightweight devices, reducing material consumption and energy requirements during production.The launch of [Company Name]'s FFC and FPC technology marks a significant milestone in the electronics industry. As companies strive to make their products smarter, more flexible, and more environmentally friendly, [Company Name] is positioning itself as a key player in this disruptive market. With its cutting-edge technology and commitment to excellence, [Company Name] is well-positioned to transform the future of electronics.About [Company Name][Company Name] is a global leader in advanced electronic solutions. With a strong focus on innovation, quality, and sustainability, the company offers cutting-edge technologies that redefine industry standards. [Company Name]'s portfolio includes a wide range of electronic components and systems for various sectors, enabling customers to create groundbreaking products for the modern world.For media inquiries, please contact:[Contact Name][Company Name][Phone Number][Email Address]###

Revolutionary Sticker Offers Innovative Solution - Unveiled in Recent News

As a company that is dedicated to producing high-quality products, we are excited to announce our latest invention - the Fpc Sticker. This innovative sticker is designed to provide a versatile and practical solution for all your labeling needs.The Fpc Sticker is a multipurpose adhesive label that is designed for use across a range of industries. It has been developed with a strong backing that provides a firm grip on any surface, making it suitable for a wide range of applications.One of the key features of our Fpc Sticker is its compatibility with a variety of printers. This makes it easy to customize the labels to meet your specific branding needs. Our product is compatible with both inkjet and laser printers and can be printed in full color. This flexibility ensures that you can create custom labels that are tailored to your business needs.The Fpc Sticker is also designed to be highly durable. It is resistant to water and chemicals, providing a long-lasting labeling solution that won't fade or peel over time.One of the key advantages of the Fpc Sticker is its ease of use. It is designed to be user-friendly, making it easy for anyone to create professional-looking labels. Our product comes with an easy-to-use software program that allows you to design your labels with minimal effort. You can also use pre-designed templates to make the process even easier.Our Fpc Sticker is also environmentally friendly. We have designed it to be made from eco-friendly materials, ensuring that our product has a minimal impact on the environment. By using our Fpc Sticker, you can ensure that your business is doing its part to reduce environmental harm.Our Fpc Sticker is available in a range of sizes and shapes, making it suitable for a variety of applications. Whether you need to label products, packaging, or equipment, our product provides a practical labeling solution that offers durability and flexibility.As a company, we are dedicated to providing our customers with innovative products that meet their unique business needs. Our Fpc Sticker is just one example of our commitment to providing practical solutions that make a real difference to our customers.In summary, our Fpc Sticker is an innovative, practical, and user-friendly labeling solution that is suitable for a wide range of applications. Its versatility, durability, and compatibility with a variety of printers make it the ideal choice for businesses of all sizes. By choosing our Fpc Sticker, you can benefit from a labeling solution that offers flexibility, practicality, and environmental sustainability.

Unlocking the Potential: Exploring the Double Sided PCB Boards' Advancements

[Company Introduction]Located in the heart of the electronics industry, the pioneering company XYZ specializes in the manufacturing and development of Electronic Printed Circuit Boards (PCBs). With over 20 years of experience, XYZ has become a leading provider of high-quality PCB solutions, catering to a wide range of industries including telecommunications, automotive, medical, aerospace, and consumer electronics.XYZ has consistently excelled in innovation, investing a significant amount in research and development to ensure their PCBs are at the forefront of technological advancements. The company's commitment to quality, reliability, and customer satisfaction has earned them a solid reputation within the industry.[Double-Sided PCB Board Revolutionizes Electronics Manufacturing]XYZ recently unveiled its groundbreaking Double-Sided PCB Board, an innovation set to revolutionize the electronics manufacturing landscape. This new product is designed to address the growing demand for smaller, more efficient, and smarter electronic devices.Traditionally, single-sided PCBs have been widely used, providing a cost-effective solution for many applications. However, advancements in technology have led to an increased need for more complex circuitry in smaller devices, paving the way for double-sided PCBs in electronic manufacturing.Double-sided PCBs offer significant advantages over their single-sided counterparts. By utilizing both sides of the circuit board, these PCBs allow for an increased component density, thereby optimizing the available space on the board. This enables manufacturers to design smaller devices, making them more compact and portable without compromising on performance.One of the key features of double-sided PCBs is the ability to create more intricate and sophisticated circuits. With a double-sided board, manufacturers can incorporate more complex functionalities, such as wireless connectivity, sensor integration, and advanced power management systems. Additionally, double-sided PCBs provide enhanced signal quality and reduced electromagnetic interference, leading to improved overall device performance.The manufacturing process for double-sided PCBs involves the deposition of a conductive material on each side of the substrate, followed by the placement and attachment of components onto both sides. This intricate process requires advanced manufacturing capabilities, precision, and expertise to ensure the robustness and quality of the final product.XYZ has invested heavily in state-of-the-art manufacturing equipment, allowing them to produce double-sided PCBs with unparalleled precision and reliability. The company employs a team of highly skilled engineers and technicians who are constantly pushing the boundaries of double-sided PCB technology, ensuring that XYZ remains at the forefront of the industry.The launch of XYZ's double-sided PCBs has sparked excitement among electronics manufacturers and designers worldwide. The new product not only enables the development of smaller, more powerful devices, but also opens up endless possibilities for innovation in various industries. From wearable technology to smart home devices, double-sided PCBs have the potential to transform the way we interact with technology.With their commitment to quality, innovation, and customer satisfaction, XYZ continues to push the boundaries of what is possible in the electronics manufacturing industry. As the demand for smaller, more efficient devices increases, XYZ's double-sided PCBs are set to play a vital role in shaping the future of electronics.

New 0.5 Mm Flexible Printed Circuit (FPC) Technology Unveiled with Exciting Innovations

Title: Leading Electronics Manufacturer Introduces Cutting-Edge 0.5 mm FPC ConnectorsIntroduction:In an era increasingly driven by technological advancements, the demand for sleek and compact electronic devices continues to rise. To meet this growing need, [Company Name], a renowned leader in electronics manufacturing, is proud to introduce its latest innovation, the revolutionary 0.5 mm FPC connector. Developed to enhance the flexibility and efficiency of electronic products, this cutting-edge technology is set to revolutionize the industry.[Company Name] - A Pioneer in Electronics Manufacturing:With decades of experience and a stellar reputation, [Company Name] has emerged as a trusted name in the electronics industry. Known for their commitment to innovation and superior quality products, the company has consistently pushed boundaries to develop state-of-the-art solutions for a wide range of applications. From consumer electronics to automotive and medical devices, [Company Name] has established itself as a key player across various sectors.The 0.5 mm FPC Connector: A Remarkable Engineering Feat:The newly launched 0.5 mm FPC connector exemplifies [Company Name]'s unwavering dedication to research and development. This groundbreaking invention is designed to support the growing need for flexible printed circuit (FPC) connectors, where space constraints demand ultra-compact solutions without compromising performance.The compact size of the 0.5 mm FPC connector ensures compatibility with an array of electronic devices, enabling seamless integration into the latest generation of smartphones, tablets, wearables, and other IoT devices. Electronics manufacturers will appreciate its slim form factor, which not only optimizes space but also simplifies manufacturing processes.Enhancing Flexibility and Reliability:One of the key advantages of the 0.5 mm FPC connector is its exceptional flexibility. This innovative technology allows for a higher degree of bending and folding, thereby accommodating various orientations within electronic devices. This enhanced flexibility empowers designers and engineers to create thinner, lighter, and more ergonomic products.Furthermore, the 0.5 mm FPC connector is engineered using high-quality materials that guarantee reliable and uninterrupted data transmission. With its superior electrical conductivity and robust construction, this connector ensures secure signal integrity, minimizing the risk of data loss or malfunctions. Manufacturers can now produce devices that deliver seamless performance, meeting the ever-increasing demands of consumers.Incorporating Advanced Features:[Company Name] understands the evolving needs of the electronics industry, and thus, the 0.5 mm FPC connector is equipped with additional advanced features. For instance, it employs gold-plated contact pads to ensure superior conductivity, while a ruggedized design enhances durability and resistance to environmental factors such as moisture and temperature variations.Furthermore, the connector's low insertion force simplifies installation, reducing the risk of damage and enabling efficient assembly processes. These features collectively enhance manufacturing efficiency and yield high-quality end products.Global Customer Reach and Customization Options:As a globally recognized brand, [Company Name] is dedicated to meeting the unique requirements of its diverse customer base. The 0.5 mm FPC connector will be readily available to electronic manufacturers worldwide, ensuring seamless integration into products produced across the globe.Additionally, [Company Name] offers customization options for the 0.5 mm FPC connector, allowing customers to tailor the solution to their specific needs. This flexibility enables electronics manufacturers to achieve optimal performance and compatibility with their respective products while streamlining their supply chain.A Visionary Step Towards the Future:The introduction of the 0.5 mm FPC connector by [Company Name] marks another significant milestone in the field of electronics manufacturing. With its exceptional flexibility, reliability, and advanced features, this revolutionary connector paves the way for next-generation electronic devices that are smaller, faster, and more efficient.As consumer demand for compact and feature-rich electronic products continues to grow, [Company Name] remains committed to driving innovation and providing cutting-edge solutions to meet evolving market needs. With the exceptional 0.5 mm FPC connector, [Company Name] reaffirms its position as a leading force in the electronics industry, empowering manufacturers to build a brighter, more connected future.

Discover the Latest Innovations in Printed Circuit Board Technology

Printing Circuit Boards Boosts Production EfficiencyIn the age of digital advancement, printed circuit boards have become ubiquitous in a wide range of electronic devices. From smartphones to airplanes, these boards play a crucial role in the functioning of modern technology. However, the production of printed circuit boards has always been time-consuming and problematic for many manufacturers. With the invention of Printing Circuit Boards (PCBs), this issue may finally be resolved.PCBs are a new kind of circuit board technology that is changing the game for manufacturers all over the world. This technology involves the use of a printer to etch copper layers onto a substrate, which forms the circuit board's design. This process offers manufacturers a faster, more precise, and cost-effective way of producing printed circuit boards, compared to traditional methods, such as chemical etching.One such company that has brought this innovative technology to the market is (Brand name removed). The Yangzhou-based firm has been in the business of producing PCBs since 2003 and has set a new standard for the industry by introducing its range of printing circuit board products.According to the company's spokesperson, "We are delighted to bring this advanced technology to our customers. We believe that by introducing this new technology, we can help our clients achieve their targets in a faster, more effective way."With their Printing Circuit Boards, the company has streamlined their manufacturing process. Unlike the traditional methods, PCB printing requires no film or photoresist production. This advantage translates into faster production times and reduced overall costs.The company's innovative technology is backed up by its team of professionals who specialize in PCB design. With over 17 years of experience in the industry, the team has developed unique expertise in the development of high-quality PCBs. Some of the key services provided by the company's design team include custom designs, engineering solutions, and cost-effective PCB prototyping.Another major advantage of PCB printing is its compatibility with a wide range of electronic applications. The company's printing circuit boards are suitable for use in various devices, from simple household appliances to complex electronic systems used in industries such as aerospace, defense, and telecommunications.Furthermore, the novel technology used to manufacture the PCBs results in boards that are more durable and robust than those produced through traditional etching methods. These boards are designed to withstand wear and tear, and their high heat resistance capability ensures that they don't overheat when exposed to high temperatures.Recent research predicts that the global circuit board market will experience significant growth in the coming years, boosted by the rapid development of the internet of things (IoT) and other emerging technologies. (Brand name removed)'s PCB printing technology has positioned them to capitalize on this growth, as they seek to establish their position as a leading player in the global printed circuit board market.In conclusion, Printing Circuit Boards have revolutionized the way electronic manufacturers produce PCBs. The technology has streamlined the production process, reduced costs, and improved overall quality. The new way of producing printed circuit boards has broader implications as more and more companies look to incorporate this technology into their production process. As the benefits are numerous, PCB printing is proving to be the future of circuit board production, and (Brand name removed) is leading the way.

Key Developments and Advancements in Flexible PCB Manufacturing Unveiled in Latest News

Title: The Rising Demand for Flexible Printed Circuit Boards (Flex PCBs)Introduction:With the ever-increasing demand for smaller, thinner, and more flexible electronic devices, the market for flexible printed circuit boards (Flex PCBs) has been experiencing exponential growth. Companies like JLCPCB have emerged as leaders in the manufacturing of high-quality, reliable, and cost-effective Flex PCBs. In this article, we will delve into the growing significance of Flex PCBs in the electronics industry and explore JLCPCB's contributions to this rapidly expanding market.Flex PCBs: Revolutionizing the Electronics Industry:Flex PCBs, also known as flexible printed wiring boards or flex circuits, have transformed the way electronic devices are designed and assembled. These innovative boards provide excellent maneuverability, allowing them to be bent, folded, and twisted without structural damage. Flex PCBs have become indispensable in devices such as smartphones, tablets, wearable technology, medical devices, and automotive applications.The Advantages of Flex PCBs:Flex PCBs offer numerous advantages over traditional rigid circuit boards, making them the preferred choice for designers and manufacturers alike. These advantages include:1. Space optimization: Flex PCBs can be manufactured in compact sizes and can be bent or folded to fit the available space, making them ideal for miniaturized devices.2. Weight reduction: The lightweight nature of Flex PCBs enhances portability, particularly in handheld and wearable electronic products.3. High reliability: Flex PCBs are more resistant to shock, vibration, and temperature fluctuations, ensuring reliable performance even in challenging environments.4. Improved signal integrity: The thin and flexible design of Flex PCBs reduces electromagnetic interference and signal loss, leading to enhanced performance in high-speed electronic applications.5. Cost efficiency: Flex PCBs can be mass-produced using automated processes, resulting in reduced production costs and increased efficiency.JLCPCB: Revolutionizing Flex PCB Manufacturing:JLCPCB, a well-established player in the electronics manufacturing industry, has been at the forefront of producing high-quality Flex PCBs. They leverage state-of-the-art manufacturing processes and cutting-edge technologies to meet the growing demand for Flex PCBs. Some key features of JLCPCB’s Flex PCB manufacturing capabilities include:1. Precision manufacturing: JLCPCB employs advanced equipment and techniques, ensuring precision and accuracy in every Flex PCB produced.2. Material versatility: They offer a wide range of material options, allowing customers to choose the most appropriate one for their specific application requirements.3. Customization: JLCPCB offers flexible solutions to meet customer-specific design requirements, assisting in the realization of unique and intricate designs.4. Prototyping and mass production: JLCPCB excels in both small-scale prototyping and mass production, providing businesses with ease and flexibility in their manufacturing processes.5. Stringent quality control: JLCPCB adheres to stringent quality control standards, ensuring that their Flex PCBs meet or exceed customer expectations in terms of performance and reliability.Future of Flex PCBs and JLCPCB's Role:The future looks promising for the Flex PCB market as the demand for thinner, lighter, and more efficient electronic devices continues to rise. JLCPCB, with its commitment to innovation and quality, is positioned to play a pivotal role in shaping this exciting evolution. The company's dedication to customer satisfaction, competitive pricing, and technological advancements will undoubtedly solidify its position as a key supplier in the Flex PCB market.Conclusion:Flexible printed circuit boards (Flex PCBs) have undoubtedly revolutionized the electronics industry, enabling the development of sleek, compact, and highly versatile electronic devices. With JLCPCB's expertise in manufacturing high-quality Flex PCBs, the industry is experiencing unprecedented growth, and the future of Flex PCBs looks extremely promising. As technology continues to advance, companies like JLCPCB will play a vital role in meeting the ever-increasing demand for flexible and reliable electronic solutions.

Stiffeners for PCBs made from FR4 are in high demand

Title: Stiffeners Revolutionizing Electronic Manufacturing: Innovative Solution for Enhanced Durability and StabilityIntroduction:In today's rapidly evolving world, electronic devices have permeated every facet of our lives. From smartphones to smart homes, these devices accompany us everywhere. However, while electronic components continue to advance, their delicate nature remains a challenge for manufacturers. To address this issue, innovative solutions such as FR4 Stiffeners are gaining traction for their ability to enhance durability and stability in electronic manufacturing.In partnership with leading electronic component manufacturers, Company XYZ has developed a groundbreaking FR4 Stiffener. This technology breakthrough is set to revolutionize the electronic manufacturing industry and ensure the longevity and reliability of crucial electronic devices.1. Understanding FR4 Stiffeners:FR4 Stiffeners are rigid, heat-resistant, and electrically insulating laminated sheets made from woven fiberglass cloth and epoxy resin. These rigid substrates are widely used in the manufacturing of electronic devices to provide structural support and enhance stability. With their exceptional mechanical strength and excellent resistance to chemicals and temperature variations, FR4 Stiffeners play a crucial role in safeguarding the delicate electronic components from external stressors.2. Applications and Benefits:(a) PCB Assembly: FR4 Stiffeners find extensive utility in printed circuit board (PCB) assembly processes. By reinforcing the PCB, these stiffeners increase the overall rigidity, prevent bending, and maintain the stability of the assembly, ultimately extending the lifespan of the electronic device.(b) LED Manufacturing: LED technologies are widely adopted across various industries, necessitating the need for reliable and long-lasting products. FR4 Stiffeners enhance the robustness of LED modules, effectively reducing the risk of damage due to mechanical stress, thermal expansion, and vibration. This leads to significantly improved performance and increased longevity of LED devices.(c) Portable Electronics: FR4 Stiffeners are also key components in ensuring the structural integrity of portable electronic devices such as smartphones, tablets, and wearables. By providing support to delicate components like screens, connectors, and buttons, stiffeners act as a defense against accidental impacts, prolonging the lifecycle of these devices.3. Product Features:(a) Mechanical Strength: FR4 Stiffeners offer exceptional mechanical strength, preventing warping and flexing of fragile electronic components. This enables devices to withstand external forces encountered during everyday use and transport.(b) Thermal Stability: The superior heat resistance properties of FR4 Stiffeners allow them to endure high-temperature environments. This resilience ensures that electronic devices can function optimally even in extreme conditions, such as automotive or industrial applications.(c) Chemical Resistance: FR4 Stiffeners exhibit excellent resistance to various chemicals, including acids and bases. This feature safeguards the electronic components against corrosion, further enhancing the reliability and longevity of the devices.(d) Customizability: Company XYZ's FR4 Stiffeners are available in a wide range of thicknesses, shapes, and sizes, allowing for customized applications to match the specific requirements of different electronic devices, significantly expanding their versatility.4. Future Prospects:The introduction of FR4 Stiffeners by Company XYZ marks a milestone in the electronics manufacturing industry. As demand and technology continue to evolve, these innovative stiffeners have the potential to redefine the standards of device durability and stability. Moreover, the partnership between Company XYZ and leading electronic component manufacturers promises further advancements in this domain, ensuring even more sophisticated applications.Conclusion:With the increasing reliance on electronic devices in everyday life, the need for ensuring their durability and stability cannot be overstated. The introduction of FR4 Stiffeners represents a significant leap forward in electronic manufacturing. These rigid substrates provide the much-needed structural support, mechanical strength, and thermal stability to electronic devices, ensuring they stand up to the demands of modern living. As the industry continues to embrace this innovative solution, Company XYZ remains at the forefront of transforming electronic manufacturing and improving product longevity for a seamless technological experience.