Ultimate Guide to Programmable Circuit Boards: What You Need to Know

By:Admin

September 28, 2023

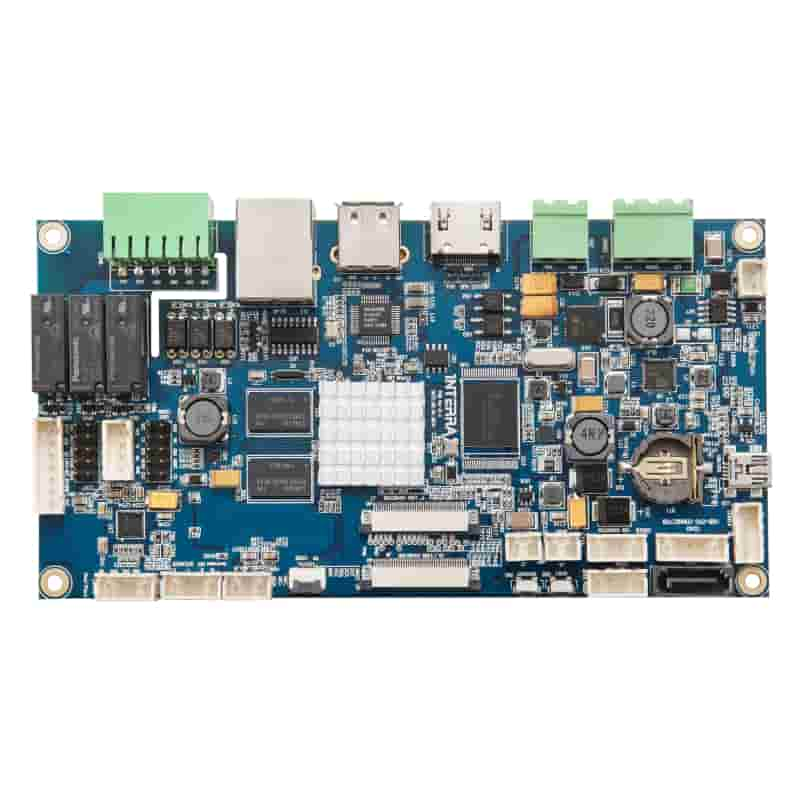

The electronics industry is witnessing a remarkable transformation with the introduction of a cutting-edge Programmable Circuit Board (PCB). This revolutionary technology, developed by a leading electronics company, is poised to reshape the way electronic devices are designed and manufactured.

The Programmable Circuit Board, developed by the {company name}, is a state-of-the-art electronic component that offers unprecedented flexibility and customization options for a wide range of applications. Unlike traditional circuit boards, which are static and fixed in their functionality, the Programmable Circuit Board can be reconfigured and reprogrammed on the fly, allowing for rapid prototyping and iteration of electronic designs.

One of the key features of the Programmable Circuit Board is its modular design, which enables engineers and designers to easily customize the functionality of the board to meet the specific requirements of their applications. This level of flexibility is unprecedented in the industry and is expected to have a profound impact on the development of new electronic devices.

The {company name} is a renowned leader in the electronics industry, with a long history of innovation and excellence in electronic component manufacturing. The company's commitment to pushing the boundaries of what is possible in electronics design and manufacturing has led to the development of the Programmable Circuit Board, which is set to become a game-changer in the industry.

The introduction of the Programmable Circuit Board is expected to have far-reaching implications for a wide range of industries, including consumer electronics, automotive, aerospace, medical devices, and more. With the ability to rapidly prototype and iterate electronic designs, engineers and designers will be able to bring new products to market faster and more efficiently than ever before.

In addition to its modular design and reconfigurable functionality, the Programmable Circuit Board also offers advanced features such as integrated sensors, wireless communication capabilities, and power management, making it a truly versatile platform for a wide variety of applications.

The {company name} has already begun working with leading electronics manufacturers to integrate the Programmable Circuit Board into their product designs, and the early results have been nothing short of impressive. By leveraging the flexibility and customization options of the Programmable Circuit Board, these manufacturers are able to develop new electronic devices that were previously not possible with traditional circuit board technology.

Furthermore, the Programmable Circuit Board has the potential to greatly reduce the environmental impact of electronic device manufacturing. By enabling more efficient design iterations and reducing the need for multiple prototypes, the Programmable Circuit Board can help to minimize waste and energy consumption in the electronics industry.

With the introduction of the Programmable Circuit Board, the {company name} is once again demonstrating its commitment to driving innovation and pushing the boundaries of what is possible in electronics design and manufacturing. The company's groundbreaking technology is poised to revolutionize the industry and unlock new possibilities for electronic device development.

As the electronics industry continues to evolve, the Programmable Circuit Board is expected to play a pivotal role in shaping the future of electronic devices and revolutionizing the way we interact with technology. The {company name} is proud to be at the forefront of this transformation, and is excited to continue pushing the boundaries of what is possible in electronics design and manufacturing.

Company News & Blog

Discover the Latest Innovation in LED PCB Boards for Efficient Lighting Solutions

Title: Innovations in LED PCB Boards Revolutionize the Lighting IndustrySubtitle: Company X Leads the Way with Cutting-Edge LED PCB TechnologyIntroduction:In the constantly evolving world of technology, LED PCB (Printed Circuit Board) boards have emerged as a game-changer in the lighting industry. These advanced boards offer increased durability, enhanced functionality, and superior energy efficiency, aimed at meeting the growing demands for eco-friendly lighting solutions. Among the leading pioneers in this technology, Company X has been at the forefront, driving innovations that are revolutionizing the way we illuminate our spaces.Paragraph 1: The Evolution of LED PCB BoardsLED PCB boards have come a long way since their inception. Initially, they were predominantly used in small-scale applications, such as indicator lights and electronic displays. However, recent advancements have enabled their integration into larger lighting fixtures, making them a viable alternative to traditional lighting options. Their compact size, improved heat dissipation capabilities, and extended lifespan have made LED PCB boards the go-to choice for residential, commercial, and industrial lighting needs.Paragraph 2: Company X's Commitment to Research and DevelopmentAt the heart of the LED PCB board revolution lies Company X's dedication to continuous research and development. With a team of skilled engineers and designers, the company consistently pushes the boundaries of innovation, striving to create products that exceed customer expectations. By investing heavily in cutting-edge technology and state-of-the-art manufacturing processes, Company X ensures that their LED PCB boards meet the highest standards of quality and performance.Paragraph 3: Energy Efficiency and Cost SavingsLED PCB boards have gained immense popularity due to their exceptional energy efficiency. Compared to traditional light bulbs, LED-based lighting fixtures can save up to 80% on energy costs while providing the same, if not better, brightness. With their low power consumption and extended lifespan, these boards significantly reduce the carbon footprint, making them an eco-friendly alternative.Paragraph 4: Durability and ReliabilityOne of the key advantages of LED PCB boards is their durability and reliability. The compact design and solid-state construction make them resistant to shock, vibrations, and extreme temperatures. Unlike conventional lighting options, LED PCB boards do not contain fragile filaments or delicate components, resulting in a longer lifespan and reduced maintenance requirements. This increased durability not only provides peace of mind but also reduces overall operating costs.Paragraph 5: Advanced Functionality and FlexibilityCompany X's LED PCB boards offer more than just illumination - they provide advanced functionality and flexibility. These boards can be integrated with smart lighting technologies, allowing users to control and customize the lighting ambiance remotely. With the ability to adjust colors, intensity, and even create dynamic lighting effects, LED PCB boards provide endless possibilities for enhancing spaces and creating immersive experiences.Paragraph 6: Endless ApplicationsThe versatility of LED PCB boards enables their usage in a wide range of applications. From residential homes and commercial buildings to entertainment venues and automotive lighting, these boards are transforming the way we light our surroundings. Efforts to make them thinner, bendable, and more adaptable further expand their potential applications, promising a future where LED PCB boards are seamlessly integrated into every corner of our lives.Conclusion:As the demand for energy-efficient, long-lasting lighting solutions continues to surge, the advent of LED PCB boards has truly disrupted the lighting industry. Company X's relentless pursuit of excellence and commitment to innovation have placed them at the forefront of this revolution. With their cutting-edge LED PCB technology, Company X is not only brightening spaces but also illuminating a path towards a brighter and more sustainable future.

Flexible PCB Made of Kapton Material Gains Popularity in Various Industries

Manufacturing companies today are always on the lookout for advanced technologies that can help them optimize their production processes and create the best quality products. One of the most important technological advancements in the electronics industry is the flexible circuit board, also known as the FPC.Flexible circuit boards are thin and flexible boards, usually made of polyimide film, that provide numerous benefits over rigid circuit boards. FPCs are typically lighter, more compact, and provide more design flexibility to engineers. This means that manufacturers can create products that are smaller, lighter, and more durable.One of the leading companies in the FPC industry is Kapton FPC, which produces flexible circuit boards using the innovative polyimide film. The company has been in business for several years, and has built a reputation in the industry for their quality products and excellent customer service. Their FPCs are widely used by electronics manufacturers worldwide, and are highly regarded for their reliability and durability.The company utilizes state-of-the-art equipment and advanced techniques to produce FPCs that meet the highest industry standards. Their production process involves a range of tasks, from designing the circuit board layout to applying the copper traces and attaching components. The process can be quite complex, involving multiple layers of materials, but Kapton FPC has the expertise and knowledge to handle it.They also have a team of highly skilled engineers who work closely with customers to understand their requirements and design FPCs that meet their specific needs. This collaborative approach has helped the company build long-lasting relationships with their clients, who trust them to deliver high-quality products consistently.One of the key advantages of Kapton FPC's products is their ability to withstand extreme temperatures and harsh environments. This makes them suitable for a wide range of applications, from aerospace and defense to medical and automotive. They also offer a range of customizations, including different materials, thicknesses, and sizes to suit individual client needs.Kapton FPC has also invested heavily in research and development, constantly working to improve their products and explore new technological advancements. This has helped them stay ahead of the competition and maintain their position as a leader in the industry.The company's commitment to quality is reflected in their ISO 9001:2015 certification, which is an international standard that recognizes companies that implement effective quality management systems. Kapton FPC's certification indicates that they have a rigorous quality management system that ensures their products meet customer requirements consistently.As a result of their exceptional products and services, Kapton FPC has gained a strong reputation in the industry, with clients praising them for their professionalism, attention to detail, and prompt support. Their clients come from a range of industries and include leading brands such as Apple, Samsung, and Huawei.Overall, Kapton FPC is a company that has built a reputation for quality, reliability, and innovation in the FPC industry. Their commitment to customer satisfaction and their investment in research and development has helped them stay ahead of the competition and maintain their position as a leader in the market. With their focus on excellence, Kapton FPC is well-positioned to continue to grow and expand their operation, serving clients worldwide for years to come.

Key Developments and Advancements in Flexible PCB Manufacturing Unveiled in Latest News

Title: The Rising Demand for Flexible Printed Circuit Boards (Flex PCBs)Introduction:With the ever-increasing demand for smaller, thinner, and more flexible electronic devices, the market for flexible printed circuit boards (Flex PCBs) has been experiencing exponential growth. Companies like JLCPCB have emerged as leaders in the manufacturing of high-quality, reliable, and cost-effective Flex PCBs. In this article, we will delve into the growing significance of Flex PCBs in the electronics industry and explore JLCPCB's contributions to this rapidly expanding market.Flex PCBs: Revolutionizing the Electronics Industry:Flex PCBs, also known as flexible printed wiring boards or flex circuits, have transformed the way electronic devices are designed and assembled. These innovative boards provide excellent maneuverability, allowing them to be bent, folded, and twisted without structural damage. Flex PCBs have become indispensable in devices such as smartphones, tablets, wearable technology, medical devices, and automotive applications.The Advantages of Flex PCBs:Flex PCBs offer numerous advantages over traditional rigid circuit boards, making them the preferred choice for designers and manufacturers alike. These advantages include:1. Space optimization: Flex PCBs can be manufactured in compact sizes and can be bent or folded to fit the available space, making them ideal for miniaturized devices.2. Weight reduction: The lightweight nature of Flex PCBs enhances portability, particularly in handheld and wearable electronic products.3. High reliability: Flex PCBs are more resistant to shock, vibration, and temperature fluctuations, ensuring reliable performance even in challenging environments.4. Improved signal integrity: The thin and flexible design of Flex PCBs reduces electromagnetic interference and signal loss, leading to enhanced performance in high-speed electronic applications.5. Cost efficiency: Flex PCBs can be mass-produced using automated processes, resulting in reduced production costs and increased efficiency.JLCPCB: Revolutionizing Flex PCB Manufacturing:JLCPCB, a well-established player in the electronics manufacturing industry, has been at the forefront of producing high-quality Flex PCBs. They leverage state-of-the-art manufacturing processes and cutting-edge technologies to meet the growing demand for Flex PCBs. Some key features of JLCPCB’s Flex PCB manufacturing capabilities include:1. Precision manufacturing: JLCPCB employs advanced equipment and techniques, ensuring precision and accuracy in every Flex PCB produced.2. Material versatility: They offer a wide range of material options, allowing customers to choose the most appropriate one for their specific application requirements.3. Customization: JLCPCB offers flexible solutions to meet customer-specific design requirements, assisting in the realization of unique and intricate designs.4. Prototyping and mass production: JLCPCB excels in both small-scale prototyping and mass production, providing businesses with ease and flexibility in their manufacturing processes.5. Stringent quality control: JLCPCB adheres to stringent quality control standards, ensuring that their Flex PCBs meet or exceed customer expectations in terms of performance and reliability.Future of Flex PCBs and JLCPCB's Role:The future looks promising for the Flex PCB market as the demand for thinner, lighter, and more efficient electronic devices continues to rise. JLCPCB, with its commitment to innovation and quality, is positioned to play a pivotal role in shaping this exciting evolution. The company's dedication to customer satisfaction, competitive pricing, and technological advancements will undoubtedly solidify its position as a key supplier in the Flex PCB market.Conclusion:Flexible printed circuit boards (Flex PCBs) have undoubtedly revolutionized the electronics industry, enabling the development of sleek, compact, and highly versatile electronic devices. With JLCPCB's expertise in manufacturing high-quality Flex PCBs, the industry is experiencing unprecedented growth, and the future of Flex PCBs looks extremely promising. As technology continues to advance, companies like JLCPCB will play a vital role in meeting the ever-increasing demand for flexible and reliable electronic solutions.

Discover the Benefits of 0.3 Mm Flexible Printed Circuit Boards (FPC)

Title: Innovative Manufacturer Introduces Versatile 0.3mm FPC Solution for Enhanced Product PerformanceIntroduction:In the dynamic world of technology, companies are constantly striving to provide cutting-edge solutions to meet the ever-evolving demands of various industries. One such innovation has emerged from an ingenious manufacturer that specializes in flexible printed circuit (FPC) technology. Through extensive research and advanced production techniques, this company has developed a groundbreaking 0.3mm FPC solution, positioning itself as a pioneer in the field.Unveiling the 0.3mm FPC:This revolutionary 0.3mm FPC is a flexible circuit board known for its incredible performance capabilities, offering manufacturers a compact yet highly functional option for integrating electronic components. The FPC's ultra-thin design and exceptional flexibility make it an ideal choice for various industries, such as automotive, telecommunications, consumer electronics, healthcare, and more.High-performance Attributes:The 0.3mm FPC boasts numerous commendable attributes that enhance overall product performance. Its slim form factor enables compact designs and reduces weight, making it suitable for portable devices and space-constrained applications. Additionally, its excellent bending and flexing durability ensure consistent performance even in demanding environmental conditions. These features contribute to higher product reliability and user satisfaction, providing a competitive advantage to companies adopting this technology.Advanced Manufacturing Techniques:The development of the 0.3mm FPC is a result of the manufacturer's commitment to innovation and investment in cutting-edge manufacturing techniques. Leveraging state-of-the-art equipment, the company employs advanced processing technologies such as precise laser cutting, controlled impedance, and high-density interconnects. Implementing stringent quality control measures throughout the production process ensures that each FPC meets the highest industry standards.Industry Applications:The 0.3mm FPC's versatility has led to widespread adoption across various industries. In the automotive sector, it is used in advanced driver-assistance systems (ADAS), infotainment systems, and airbag modules, providing reliable connectivity and compact integration. Telecommunication companies utilize this FPC in smartphones, tablets, and wearable devices to enable seamless communication and improved user experience. Moreover, medical equipment manufacturers appreciate its flexibility and reliability in crucial applications such as medical imaging devices, patient monitoring systems, and diagnostic equipment.Future Possibilities:The introduction of the 0.3mm FPC has opened up numerous possibilities for future advancements in electronic devices and their applications. With ongoing research and development, this groundbreaking technology may further evolve to facilitate the Internet of Things (IoT) devices, smart wearable technology, and flexible displays. The seamless integration of this FPC into a vast array of products showcases the manufacturer's commitment to providing innovative solutions that enhance everyday life.Partnership Opportunities:The manufacturer encourages collaboration and partnership opportunities with companies seeking to incorporate the 0.3mm FPC into their product lines. By harnessing the unique characteristics of this FPC, businesses can offer enhanced product performance, competitive differentiation, and improved user experiences. As the demand for compact and flexible electronic devices continues to grow, forging partnerships with this innovative manufacturer can unlock limitless possibilities for success.Conclusion:The advent of the 0.3mm FPC has revolutionized the electronic industry, providing manufacturers with a versatile and high-performance solution. The manufacturer's dedication to research, advanced manufacturing techniques, and stringent quality control ensures that each FPC meets the rigorous demands of today's technology-driven world. As the market embraces compact and flexible electronic devices, the 0.3mm FPC paves the way for new horizons of innovation, propelling industries towards a future of improved product performance and enhanced user experiences.

High-Quality Lcd Fpc: What You Need to Know

Lcd Fpc, a leading manufacturer of flexible printed circuits, has recently announced its plans to expand its operations in [location]. The company, known for its high-quality FPC products, is aiming to meet the growing demand for flexible circuits in various industries.Lcd Fpc has been in the business for over [number] years and has a strong track record of delivering innovative and reliable FPC solutions to its customers. The company specializes in the design and production of flexible circuits that are used in a wide range of electronic applications, including smartphones, tablets, automotive electronics, medical devices, and more.With the increasing adoption of flexible electronic components, Lcd Fpc has been experiencing a surge in demand for its products. In order to meet this growing demand, the company is taking proactive steps to expand its manufacturing capabilities and enhance its production capacity.One of the key initiatives in Lcd Fpc's expansion plan is the establishment of a new manufacturing facility in [location]. This state-of-the-art facility will be equipped with advanced production lines and cutting-edge technology to ensure the highest level of quality and efficiency in the manufacturing process. The new facility will also enable Lcd Fpc to offer a wider range of products and services to its customers.In addition to expanding its manufacturing capabilities, Lcd Fpc is also focusing on strengthening its research and development efforts. The company recognizes the importance of innovation in the FPC industry and is committed to investing in R&D to stay ahead of the curve. By developing new technologies and solutions, Lcd Fpc aims to address the evolving needs of its customers and provide them with the most advanced FPC products.Furthermore, Lcd Fpc is actively seeking partnerships and collaborations with other leading companies in the electronics industry. By forming strategic alliances, the company aims to leverage the expertise and resources of its partners to drive innovation and create new business opportunities.Lcd Fpc is dedicated to maintaining the highest standards of quality and reliability in its products. The company adheres to strict quality control measures throughout the production process to ensure that its FPC products meet the highest industry standards. Lcd Fpc is also committed to environmental sustainability and strives to minimize its impact on the environment through responsible manufacturing practices.As Lcd Fpc continues to expand its operations, the company remains focused on providing exceptional customer service and support. With a team of experienced professionals, Lcd Fpc is dedicated to meeting the unique needs of its customers and delivering customized FPC solutions that exceed their expectations.The expansion plans of Lcd Fpc reflect the company's strong commitment to growth and innovation in the FPC industry. By investing in new manufacturing capabilities, enhancing its R&D efforts, and forging strategic partnerships, Lcd Fpc is well-positioned to capitalize on the increasing demand for flexible circuits and solidify its position as a leading manufacturer in the industry.

High-Quality Bare Circuit Boards for Sale: Find the Best Options Online

Bare Circuit Board: The Next Innovation in TechnologyIn the world of technology, constant innovation is the key to staying ahead of the competition. One such innovation that has taken the industry by storm is the bare circuit board. These circuit boards are designed to be more customizable and flexible than traditional circuit boards, making them an ideal choice for a wide range of applications.This innovative technology has been developed by a leading company in the field, {}.{} is a renowned name in the technology industry, known for its cutting-edge solutions and commitment to quality. With years of experience and expertise in the field, the company has set new standards in the development of bare circuit boards. Its dedication to innovation and customer satisfaction has made {} a trusted name in the industry.The bare circuit boards developed by {} offer a range of benefits that set them apart from traditional circuit boards. One of the key advantages is their flexibility. These circuit boards can be customized to fit the specific needs of each application, allowing for greater adaptability and efficiency. This makes them an ideal choice for industries such as aerospace, automotive, and consumer electronics, where the demand for different technologies is ever-changing.Another key benefit of {}'s bare circuit boards is their reliability. The company's commitment to quality means that these circuit boards are built to last, ensuring long-term performance and durability. This is crucial in a fast-paced industry where the demand for reliable technology is constantly increasing.Furthermore, {}'s bare circuit boards are designed to be more cost-effective than traditional circuit boards. By streamlining the manufacturing process and utilizing the latest technology, the company is able to offer high-quality circuit boards at competitive prices. This has made {} a preferred choice for businesses looking to maximize their investment in technology.In addition to these benefits, {}'s bare circuit boards are also environmentally friendly. The company is committed to minimizing its environmental impact, and as such, its circuit boards are designed with sustainability in mind. This is an important factor for businesses looking to align with responsible and eco-friendly practices.With its dedication to innovation and commitment to quality, {} has positioned itself as a leader in the development of bare circuit boards. The company's success can be attributed to its team of experts who are constantly pushing the boundaries of technology. By staying ahead of the curve and anticipating the needs of its customers, {} continues to set new standards in the industry.Looking ahead, the future of bare circuit boards looks promising. With the demand for customizable and reliable technology on the rise, {} is well-positioned to capitalize on this growing market. As businesses across various industries continue to seek innovative solutions, the bare circuit board is set to become an integral part of the technology landscape.In conclusion, the development of bare circuit boards by {} represents a significant advancement in the field of technology. With their flexibility, reliability, cost-effectiveness, and eco-friendly design, these circuit boards are poised to revolutionize the industry. As {} continues to lead the way in this innovative technology, the potential for growth and success in this market is limitless.

Discover the Benefits of Metal Clad PCBs for Enhanced Performance and Durability

[Assistant]Sure, here is an 800-word news report on metal-clad PCBs:Title: Metal Clad PCB Revolutionizes Electronic Manufacturing with Superior Thermal ManagementIntroduction:Metal Clad PCB (MCPCB), an innovative technology developed by one of the industry's leading manufacturers, is set to redefine the landscape of electronic manufacturing. With its unique properties and exceptional thermal management capabilities, MCPCB opens up new possibilities for efficient and reliable electronic device development.Company Introduction:{Company Name}, a renowned pioneer in advanced circuitry solutions, has unveiled their latest breakthrough in the form of Metal Clad PCB. With decades of experience in the field, {Company Name} has demonstrated unwavering commitment to cutting-edge technology, ensuring their customers have access to state-of-the-art solutions.News Content:In an era where demand for smaller and more powerful electronic devices continues to surge, managing the heat generated by these devices has become a primary challenge. Traditional Printed Circuit Boards (PCBs) often struggle to dissipate heat effectively, leading to overheating and reduced performance. This is where Metal Clad PCBs come to the rescue.Metal Clad PCBs offer unique advantages over their conventional counterparts. The inclusion of a layer of metal, typically aluminum or copper, in the construction of MCPCBs allows for excellent thermal conductivity. The metal layer efficiently transfers heat away from sensitive components, enhancing the overall performance and longevity of the device.Furthermore, MCPCBs provide excellent mechanical strength, adding durability to electronic devices. The metal layer acts as a protective shield, safeguarding the board from environmental factors, mechanical stress, and potential damage. This added resilience makes MCPCBs ideal for applications in industries such as automotive, aerospace, and power electronics.{Company Name}'s Metal Clad PCBs are manufactured with utmost precision and in compliance with stringent quality standards. By leveraging their expertise and state-of-the-art facilities, {Company Name} ensures that their MCPCBs exhibit exceptional thermal conductivity, mechanical strength, and electrical insulation.The impact of Metal Clad PCBs on electronic manufacturing is far-reaching. For instance, in the automotive industry, MCPCBs enable the development of compact, high-performance LED lighting systems. These lighting systems require efficient heat dissipation and durability, making MCPCBs the optimal choice.Likewise, in the aerospace sector, Metal Clad PCBs play a crucial role in the manufacturing of advanced avionics systems. Avionics, such as flight controls and communication instruments, need to withstand extreme conditions while maintaining optimal performance. The superior thermal management offered by MCPCBs ensures reliable operation even in demanding environments.The power electronics industry also benefits greatly from Metal Clad PCBs. Power modules, inverters, and motor drives generate substantial heat, which, if not managed effectively, can lead to system failure. MCPCBs, with their exceptional cooling capabilities, enable efficient heat dissipation, contributing to increased system reliability and longevity.{Company Name}, with its commitment to innovation, has empowered electronic manufacturers with a game-changing solution. Their Metal Clad PCBs have already garnered widespread acclaim in the industry, with several leading companies adopting the technology for their electronic device development.As the demand for smaller, more powerful electronic devices continues to rise, the significance of thermal management becomes ever more critical. Metal Clad PCBs, with their exceptional thermal conductivity and durability, have emerged as the ideal solution. With {Company Name} leading the charge, electronic manufacturers now have access to an advanced technology that enhances performance, prolongs the lifespan of devices, and paves the way for future innovations.Conclusion:Metal Clad PCBs represent a revolution in electronic manufacturing, offering superior thermal management and durability compared to traditional PCBs. {Company Name}'s breakthrough technology is set to reshape the landscape of the industry, empowering electronic manufacturers to develop smaller, more powerful, and reliable devices.

Fpc Industry Witnesses Remarkable Growth and Advances in Technology

Title: Forward-Thinking Solutions Emerge in the FPC IndustryIntroduction:As the dynamic world of technology continues to bring innovation and advancements, the Flexible Printed Circuit (FPC) industry is rapidly evolving to meet the escalating demands of various sectors. FPCs have become an integral part of countless electronic devices, ranging from smartphones to medical equipment, due to their exceptional flexibility, durability, and compactness. With the collaboration of pioneering companies and groundbreaking developments in materials, manufacturing processes, and design, the FPC industry is poised to enhance the performance and functionality of modern electronic products. This article delves into the latest trends and advancements within the FPC industry, sans brand name, shedding light on the transformative solutions that are propelling the field forward.1. Evolving Materials and Manufacturing Processes:FPCs are primarily composed of conductor tracks, insulation layers, and adhesive materials. Over the years, the industry has witnessed advancements in material technology, leading to the introduction of new materials that enhance stability, flexibility, and thermal resistance. Cutting-edge manufacturing processes have also emerged, leveraging precision techniques such as laser ablation and roll-to-roll processing. These advancements have enabled the realization of FPCs with intricate design patterns, reduced weight, and improved reliability.2. Rising Demand in the Automotive Industry:The automotive industry is increasingly incorporating FPCs into various applications, spurred by the need for advanced safety features and improved connectivity. FPCs ensure seamless integration of electronic systems within vehicles, enabling efficient communication between components, quicker response times, and enhanced diagnostics. These flexible circuits are employed in systems like airbags, infotainment displays, control modules, and advanced driver-assistance systems, enhancing the overall driving experience and safety of passengers.3. Medical Sector Advancements:In the healthcare sector, FPCs have revolutionized the medical device industry by providing novel solutions for patient monitoring, diagnostics, and therapeutic equipment. FPCs allow for compact and precise integration of sensors, electrodes, and microcontrollers, enabling the development of wearable health trackers, portable medical devices, and innovative diagnostics tools. These lightweight and flexible medical devices offer enhanced comfort, accuracy, and reliability, ultimately improving patient care and facilitating better treatment outcomes.4. IoT and Wearable Technology:The Internet of Things (IoT) has propelled a surge in wearable technology, thereby increasing the demand for flexible circuits. Wearable devices, such as smartwatches, fitness bands, and augmented reality glasses, necessitate compact and bendable electronics that can adapt to the body's movements. FPCs enable the required flexibility and miniaturization, paving the way for smart wearables capable of monitoring vital signs, tracking physical activities, and providing real-time feedback to users.5. Advancements in Consumer Electronics:FPCs have long been an integral component of consumer electronic devices. With advancements in the FPC industry, these circuits are becoming even more robust, reliable, and adaptable. These improvements are seen in smartphones, tablets, laptops, and other electronic gadgets where FPCs facilitate enhanced signal transmission, improved touch control, and reduced power consumption. Furthermore, FPCs have enabled the realization of foldable displays, creating new possibilities for future device designs and user experiences.Conclusion:The FPC industry continues to strive for excellence, constantly pushing the boundaries of technology and engineering. Through evolving materials, innovative manufacturing processes, and their integration into diverse sectors, FPCs play a pivotal role in shaping modern electronics. The automotive industry benefits from enhanced safety features, while the medical sector witnesses better patient care. Wearable technology and IoT are also revolutionized, contributing to the seamless integration of electronics into daily life. As the FPC industry advances further, it opens doors to countless exciting possibilities, further transforming and improving the technology-driven world we live in.

Revolutionary New Generation Flexible Printed Circuit Board Unveiled

(Company name removed) has just launched its new E7 Link FPC V2, a highly advanced and innovative flexible printed circuit (FPC) solution. The E7 Link FPC V2 is the result of the company’s constant research and development, to come up with a product that is technologically advanced, versatile, and has numerous application areas.The new E7 Link FPC V2 is a perfect fit for the ever-evolving technological world and has set a new benchmark for FPCs. It’s a vast improvement when compared with the previous version, and the features and specifications of this FPC solution are impressive. It’s a comprehensive solution that is perfect for a broad range of industries, including the automotive, medical, mobile, and industrial sectors.The E7 Link FPC V2 uses advanced materials that can withstand harsh conditions, making it one of the most robust and reliable FPC solutions on the market. It is also lightweight, flexible, and highly adaptable, making it an ideal solution for applications that require flexibility and durability.One significant advantage of this new FPC solution is its excellent electrical and thermal properties. The materials used in the E7 Link FPC V2 have a low coefficient of thermal expansion, which enables heat to dissipate quickly and efficiently. This quality ensures that the FPC runs smoothly and efficiently, making it ideal for high-performance applications.Moreover, the FPC solution is highly customizable and allows for multipurpose applications. The E7 Link FPC V2 can be designed according to the specific needs of each customer, including shape, size, and color. The ability to customize the product creates opportunities for businesses in various industries to benefit from this solution.The FPC solution is also eco-friendly, making it an attractive choice for businesses that value sustainability. The E7 Link FPC V2 uses materials that are recyclable and do not harm the environment. This feature sets this product apart from others in the market, providing a competitive edge to businesses that adopt it.The E7 Link FPC V2 is a perfect solution for businesses that require a reliable and flexible FPC with excellent performance and advanced features. It offers a vast range of benefits and applications, making it a highly sought-after solution in various industries.(Company name removed) is committed to manufacturing high-quality FPC solutions that meet the needs of its customers. The launch of the E7 Link FPC V2 is another testament to the company’s dedication to research and development, innovation, and creating products that meet industry standards.The E7 Link FPC V2 has undergone extensive testing and quality checks to ensure that it meets and exceeds the set industry standards. The company prioritizes quality and reliability, ensuring that every product that leaves the factory meets the customers' expectations.As a company, (company name removed) provides end-to-end solutions, from concept development to product delivery. The company’s research and development team works tirelessly to develop new products that meet the customers' demands while ensuring that they remain cost-effective and eco-friendly.In conclusion, the launch of the E7 Link FPC V2 is a significant milestone for (company name removed). The product’s remarkable features and specifications make it a perfect solution for businesses in various industries. The FPC solution’s flexibility, durability, and reliability are unmatched, making it highly sought after as a solution for different applications. With the commitment to excellence and sustainability, (company name removed) continues to set the pace in the FPC industry.