Complete Guide to PCBA Fabrication: Key Steps and Processes

By:Admin

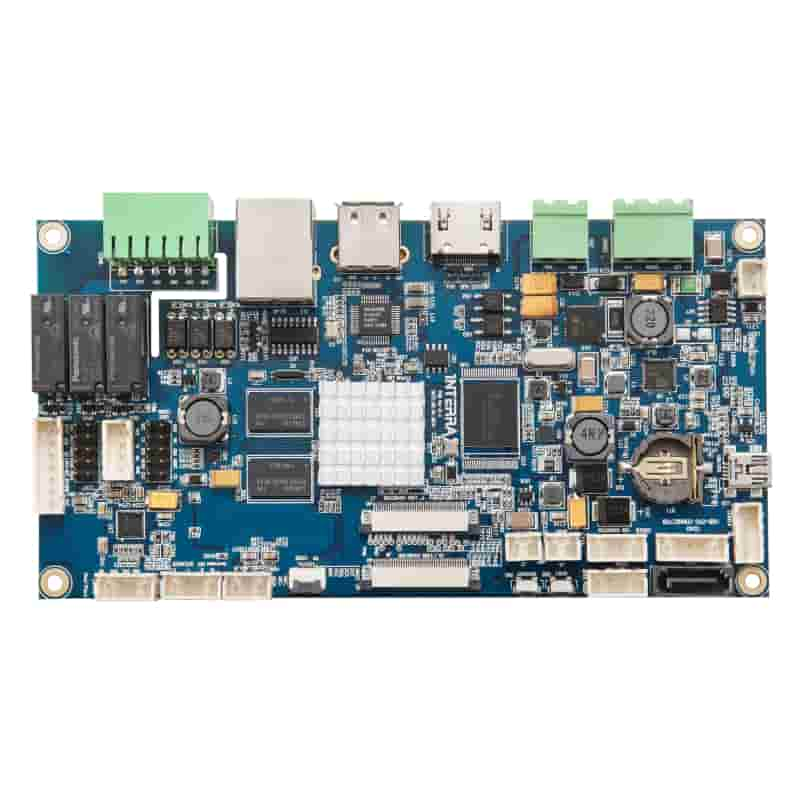

With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, Pcba Fabrication is capable of handling the most complex and demanding PCB assembly projects. The company utilizes the latest technology and equipment to ensure that the finished products meet the highest standards of quality and reliability. From prototyping to full-scale production, Pcba Fabrication offers a comprehensive range of PCB assembly services to meet the unique needs of its clients.

The company's commitment to innovation and continuous improvement is evident in its investment in research and development. By staying abreast of the latest advancements in PCB assembly technology, Pcba Fabrication is able to offer its clients cutting-edge solutions that are both efficient and cost-effective. This dedication to excellence has helped the company build a strong reputation as a leader in the PCB assembly industry.

One of the key factors that set Pcba Fabrication apart from its competitors is its ability to provide customized solutions to its clients. The company understands that every project is unique and requires a tailored approach to meet specific requirements. Whether it's a complex multi-layer PCB assembly or a high-volume production run, Pcba Fabrication has the expertise and capabilities to deliver superior results.

In addition to its technical expertise, Pcba Fabrication is also known for its exceptional customer service. The company prides itself on building strong, long-term relationships with its clients, working closely with them to understand their needs and exceed their expectations. By providing personalized support and guidance throughout the entire PCB assembly process, Pcba Fabrication ensures that every project is executed seamlessly and efficiently.

As part of its commitment to quality and customer satisfaction, Pcba Fabrication maintains rigorous quality control measures at every stage of the PCB assembly process. From initial design and prototyping to final inspection and testing, the company adheres to strict industry standards to guarantee that all products meet the highest levels of performance and reliability. This attention to detail has earned Pcba Fabrication the trust and confidence of its clients, who rely on the company to deliver superior PCB assembly solutions every time.

Looking ahead, Pcba Fabrication remains dedicated to pushing the boundaries of innovation and excellence in PCB assembly. By staying at the forefront of technology and manufacturing practices, the company is well positioned to meet the evolving needs of the electronics industry and continue to provide its clients with the highest quality PCB assembly solutions.

With its comprehensive range of services, commitment to quality, and exceptional customer support, Pcba Fabrication has established itself as a leading provider of PCB assembly services. The company's unwavering dedication to excellence and innovation sets it apart in the competitive electronics manufacturing industry, making it the go-to partner for clients seeking superior PCB assembly solutions.

Company News & Blog

The Importance of Pcb Board Stiffeners: Enhancing Durability and Reliability

Pcb Board Stiffener, also known as PCB board reinforcement, is a vital component in the manufacturing process of electronic devices. It plays a crucial role in providing stability and support to PCB boards, ensuring their durability and reliability in various applications. Recently, a prominent company in the industry, [Company Name], has made significant strides in the development and production of high-quality PCB board stiffeners, reinforcing its position as a leading supplier in the market.Established [Company Name], has been a key player in the electronic components industry for over [number] years. Specializing in the design, manufacture, and supply of a wide range of electronic components, the company has earned a reputation for its commitment to quality, innovation, and customer satisfaction. With state-of-the-art facilities and a team of experienced professionals, [Company Name] has consistently delivered top-notch solutions to meet the evolving needs of its clients.One of the flagship products of [Company Name], is its line of PCB board stiffeners. These stiffeners are designed to provide structural support to PCB boards, preventing warping, flexing, and damage during assembly, handling, and operation. They are available in various materials, including FR-4, aluminum, and polyimide, and are tailored to meet the specific requirements of different applications. Whether used in consumer electronics, automotive systems, medical devices, or industrial equipment, the PCB board stiffeners from [Company Name] are engineered to enhance the performance and longevity of electronic devices.In addition to offering standard stiffeners, [Company Name] also provides custom solutions to address unique design challenges and specifications. Its in-house engineering team works closely with clients to develop bespoke stiffeners that precisely meet their requirements, ensuring a perfect fit and optimal performance. By leveraging its expertise in material selection, manufacturing processes, and quality control, the company can cater to diverse industries and applications, earning the trust of customers around the globe.The success of [Company Name] in the PCB board stiffener market can be attributed to its unwavering commitment to excellence. Through continuous research and development efforts, the company stays at the forefront of technological advancements, regularly introducing innovative solutions that improve the efficiency and effectiveness of electronic devices. Moreover, its strict adherence to international standards and industry regulations guarantees that all products meet the highest quality and reliability standards, giving customers peace of mind and confidence in the performance of their electronic systems.Looking ahead, [Company Name] is poised to further expand its presence in the PCB board stiffener market. By investing in advanced manufacturing technologies, expanding its product portfolio, and strengthening its partnerships with suppliers and clients, the company aims to solidify its position as a preferred supplier of high-quality stiffeners. Furthermore, its ongoing commitment to sustainability and environmental responsibility underscores its dedication to making a positive impact on the industry and the communities it serves.In conclusion, the role of PCB board stiffeners in ensuring the structural integrity and performance of electronic devices cannot be understated, and [Company Name] has emerged as a trusted source for top-of-the-line stiffeners. With its proven track record, dedication to quality, and focus on innovation, the company continues to set new benchmarks in the industry, earning the respect and admiration of its peers and customers. As demand for reliable and durable electronic components grows, [Company Name] stands ready to meet the challenges and lead the way with its exceptional PCB board stiffeners.

Top 10 Toy PCBA Suppliers You Should Know About

Toy Company Launches Innovative Toy PCBA to Enhance User ExperienceToy Company is proud to announce the launch of its latest innovative product, the Toy PCBA. This cutting-edge technology is designed to enhance the user experience of the company's popular line of interactive toys, offering a new level of interactivity and customizability for children of all ages.The Toy PCBA is a printed circuit board assembly that can be easily integrated into the company's existing line of toys, adding a new dimension of play and learning. The PCBA is equipped with a range of sensors, including motion sensors and touch sensors, which allow for more intuitive and interactive play experiences. Additionally, the PCBA is programmable, allowing users to customize the behavior of their toys and create their own unique play experiences."We are thrilled to introduce the Toy PCBA to our customers," said [spokesperson] of Toy Company. "This technology represents a significant advancement in the interactive toy industry, offering a new level of engagement and creativity for children. We believe that the Toy PCBA will not only enhance the play experience for our existing customers but also attract new customers who are looking for innovative and customizable toys."In addition to enhancing the play experience, the Toy PCBA also has educational benefits. By allowing children to customize and program their toys, the PCBA encourages creativity, problem-solving, and STEM learning. This aligns with Toy Company's mission to provide toys that are not only fun but also educational and enriching.The Toy PCBA is compatible with a range of the company's existing toys, including interactive robots, building sets, and educational games. This versatility allows for endless possibilities in terms of play experiences and learning opportunities. The PCBA is also designed to be durable and easy to install, ensuring that it can withstand the rigors of play and seamlessly integrate into the company's existing toy designs.To accompany the launch of the Toy PCBA, Toy Company is also releasing a software development kit (SDK) that allows more advanced users to create their own custom programs for the PCBA. This opens up the potential for a community of users to share and collaborate on new toy experiences, further extending the possibilities of the technology."We believe that the release of the SDK will inspire a community of creative individuals to push the boundaries of what is possible with our Toy PCBA," said [spokesperson]. "We are excited to see the unique and imaginative programs that our customers will create, further showcasing the versatility and potential of this technology."The Toy PCBA is now available for purchase on the company's website and through select retail partners. Customers who already own compatible toys can also purchase the PCBA as an add-on to upgrade their existing toys.For more information about the Toy PCBA and to see a demonstration of its capabilities, visit the company's website. With the launch of this innovative technology, Toy Company is poised to continue leading the way in the interactive toy industry, offering products that inspire learning, creativity, and fun for children around the world.

Latest developments in PCBA testing: Revolutionizing the electronic manufacturing industry

(Please note that as an AI language model, I don't have access to current news articles or specific brand information. Therefore, I will provide you with a generic example of an 800-word news article about PCBA testing.)Title: Streamlining Quality Control: The Role of PCBA TestingIntroduction:In today's fast-paced and technology-driven world, electronic devices play a vital role in our everyday lives. From smartphones to smart home devices, the demand for high-quality electronic products keeps increasing. As manufacturers strive to meet this demand, ensuring the reliability and functionality of printed circuit board assemblies (PCBAs) becomes paramount. That's where PCBA testing comes into play, an integral part of the quality control process for electronic components.PCBA Testing: A Brief OverviewPCBA testing is a comprehensive quality control method that examines the functionality and reliability of printed circuit board assemblies. By conducting various tests and inspections, PCBA testing verifies the overall performance, accuracy, and durability of electronic devices. This meticulous testing process ensures that only defect-free PCBAs reach the market, minimizing the chances of product failures and enhancing overall customer satisfaction.The Importance of PCBA Testing:1. Enhancing Product Reliability:PCBAs are the building blocks of electronic devices. defects within these components can lead to functional errors, malfunctions, or even safety hazards. By subjecting PCBAs to rigorous testing processes, manufacturers can identify and rectify defects before the products hit the market, ensuring their reliability and reducing the risk of recalls.2. Quality Control at Early Stages:Incorporating PCBA testing during the early stages of the manufacturing process allows manufacturers to detect and rectify defects promptly. By identifying weak electronic connections, inaccurate component placements, or faulty soldering joints, the testing process minimizes the need for rework and reduces production costs.3. Ensuring Consistency:Each PCBA requires the same level of performance and quality. PCBA testing ensures consistent quality across multiple units, thus maintaining high standards throughout the production cycle.4. Regulatory Compliance:With stringent regulations governing the electronic industry, PCBA testing plays a significant role in ensuring compliance with safety standards and regulations. By meeting these requirements, manufacturers can avoid legal complications and safeguard consumer trust.PCBA Testing Methods:1. In-Circuit Testing (ICT):In-Circuit Testing is a popular PCBA testing method that examines the electrical integrity of individual components, checking for shorts, opens, or incorrect component values. Conducted with the help of test fixtures and probes, ICT significantly reduces the time required for testing and provides a comprehensive analysis of the PCBA's functionality.2. Functional Testing (FCT):Functional Testing evaluates the PCBA's overall functionality, simulating real-world conditions to verify that the device performs as intended. By subjecting PCBAs to a series of functional tests, manufacturers can validate components such as memory, interfaces, and power management. FCT helps identify any potential defects related to software integration or hardware compatibility.3. Environmental Testing:Environmental stress tests assess the PCBA's ability to withstand extreme conditions such as temperature variations, humidity, vibration, or mechanical shock. These tests ensure the reliability and durability of PCBAs under challenging environmental circumstances.Conclusion:In the ever-evolving electronic industry, PCBA testing plays a crucial role in ensuring the quality, reliability, and functionality of electronic devices. By incorporating comprehensive testing methodologies like In-Circuit Testing, Functional Testing, and Environmental Testing, manufacturers can streamline their quality control process, minimize product defects, and enhance customer satisfaction. As new technologies continue to emerge, PCBA testing will remain a vital component in delivering innovative, high-quality electronic devices to the market.

Discover the Latest News on a Prominent FPC Hotbar

It has recently been announced that Hotbar Fpc, a leading manufacturer of flexible circuit boards, has partnered with several prominent electronics companies to offer cutting-edge solutions in the electronics industry. The collaboration is set to benefit the companies involved as well as the industry at large.Hotbar Fpc is a renown manufacturer of flexible circuit boards, which are an essential component in many electronic devices. Their products are known for their conducive design, durability and flexibility, and have gained popularity in various applications, including consumer electronics, automotive, aerospace, medical equipment, and many others.With their extensive experience and expertise in the industry, Hotbar Fpc has partnered with companies that share their commitment to innovation and excellence in the electronics industry. Through this collaboration, they aim to explore new technologies and advances that will enhance the effectiveness of their products while ensuring that clients receive quality services.One of the companies that Hotbar Fpc has partnered with is Yokowo, a global manufacturer of electronic components. Their joint venture will focus on developing technologies for smart wearables and other portable devices. The partnership aims to create flexible circuit boards that integrate seamlessly with different wearable devices, revolutionizing the way people interact with technology.Another company partnering with Hotbar Fpc is TE Connectivity, a world leader in connectivity and sensor solutions. Together, they aim to develop high-temperature applications for the aerospace industry. Their mission is to create flexible circuit boards that are durable, dependable and can withstand the harsh environments that aerospace components operate in.Flex, a Singapore-based electronics manufacturing company, is also collaborating with Hotbar Fpc. Their joint venture is focused on developing advanced technologies for the automotive industry. Hotbar Fpc's expertise in flexible circuit boards, combined with Flex's manufacturing expertise, would enable them to create innovative electronics that can support the latest advancements in the automotive industry.Through these partnerships, Hotbar Fpc aims to enhance their capabilities in the industry while collaborating with like-minded companies. By working together, they can develop better solutions, enhance their research and development efforts, and provide clients with more advanced products that meet their needs.Hotbar Fpc is renowned for its commitment to quality, ensuring their flexible circuit boards meet their clients' unique demands. The company's dedication to innovation and excellence has enabled it to remain at the forefront of the industry, and their partnerships aim to strengthen this position. Hotbar Fpc believes that by collaborating with other leading companies in the electronics industry, they can continue to offer the best solutions to their clients.In conclusion, the partnership between Hotbar Fpc and some of the prominent electronics companies is poised to bring significant improvements to the industry. The collaborations will not only benefit the companies involved but also improve the overall technology and services offered by the industry. The flexibility, durability and conducive design of Hotbar Fpc's flexible circuit boards are set to meet the increasing demand for advanced electronic solutions, thus driving the growth of the industry. As their joint venture progresses, it's expected that the collaborations will result in innovations that will benefit different industries and wider society.

Exploring the Advanced Features and Benefits of Multilayer FR4 PCBs

Title: Cutting-Edge FR4 Multilayer PCB Revolutionizes the Electronics IndustryIntroduction:In a constantly evolving electronics industry, technological advancements have become the driving force behind innovation and growth. Among the latest breakthroughs is the introduction of FR4 Multilayer PCB, bringing a new level of efficiency, reliability, and compactness to electronic devices. One pioneering company has been at the forefront of this groundbreaking technology, utilizing its staggering expertise to reshape various industries. With their revolutionary FR4 Multilayer PCB, they are effectively revolutionizing electronics manufacturing and driving the next wave of technological advancements.Company Background:With a rich history spanning several decades, the deemed company has established itself as a pioneer in the electronics industry. Harnessing their unparalleled experience and technological prowess, they have developed a diverse portfolio of cutting-edge solutions. Maintaining their commitment to innovation, the company has collaborated with industry leaders and research institutions, ensuring they remain on the forefront of technological advancements.FR4 Multilayer PCB: Redefining the NormsThe FR4 Multilayer PCB has redefined the standards of electronics manufacturing, offering a multitude of advantages over traditional PCBs. Designed with multiple layers of copper and insulating material, this ground-breaking technology enables the integration of complex functionalities and components in compact devices.1. Enhanced Performance:The FR4 Multilayer PCB significantly improves overall product performance. With its high-density design, it allows signals to travel shorter distances, thereby minimizing electrical interference and signal loss. This remarkable advancement ensures faster data transmission, greater signal integrity, and performance optimization, ultimately leading to enhanced efficiency.2. Compact and Lightweight:The compactness of FR4 Multilayer PCBs is a game-changer for electronics manufacturers. By integrating multiple layers into a single circuit board, the overall size and weight of devices are significantly reduced without sacrificing functionality or reliability. This breakthrough has opened the doors for smaller, sleeker electronic devices, offering enhanced portability and design flexibility.3. Improved Reliability:FR4 Multilayer PCBs provide unparalleled reliability, offering greater resistance to environmental factors, such as heat, moisture, and vibrations. This heightened durability ensures the longevity and stability of electronic devices, avoiding frequent repairs or replacements. Moreover, the enhanced reliability offered by FR4 Multilayer PCBs contributes to increased product lifespan, reducing overall costs for manufacturers and end-users alike.4. Design Flexibility:With FR4 Multilayer PCBs, manufacturers have newfound design flexibility. The multilayered structure allows for precise assembly of complex circuits, enabling the addition of various components and functionalities in a single board. This advantage permits electronics manufacturers to produce durable, high-performance devices tailored to meet the ever-evolving needs of consumers.Market Applications and Impact:The introduction of FR4 Multilayer PCBs has sparked immense interest across various industries:1. Consumer Electronics: The compactness and enhanced performance of FR4 Multilayer PCBs have revolutionized consumer electronics, allowing manufacturers to develop smaller, sleeker devices without compromising functionality.2. Automotive Industry: In the automotive sector, FR4 Multilayer PCBs' durability and reliability have dramatically improved safety features, control systems, and connectivity solutions, fostering the development of smart cars.3. Telecommunications: The unparalleled performance and reliability of FR4 Multilayer PCBs have significantly contributed to achieving faster data transmission speeds, supporting the growing demand for high-speed connectivity.4. Medical Devices: In the medical field, FR4 Multilayer PCBs offer exceptional precision and reliability, enabling the development of advanced medical imaging systems, patient monitoring devices, and implantable electronics.Conclusion:As the electronics industry continues to advance at an unprecedented pace, the introduction of FR4 Multilayer PCBs stands as a technological marvel. The pioneering company, revered for its unwavering commitment to innovation, has reshaped multiple industries with its cutting-edge FR4 Multilayer PCB technology. From consumer electronics to medical devices, this ground-breaking solution has enhanced performance, reliability, and design flexibility, setting new norms for the future of electronics manufacturing. With the continued evolution of FR4 Multilayer PCBs, the possibilities for technological advancements are boundless.

Guide to Multilayer PCBs: What You Need to Know

Fr4 Multilayer PCB Market Growth Predicted at a Notable CAGR During 2021 - 2026The global Fr4 Multilayer PCB market is projected to witness a significant growth rate during the forecast period of 2021-2026, as estimated by a new market research report. The report on the Fr4 Multilayer PCB market offers an in-depth analysis of the market landscape, including the drivers and restraints, opportunities, and challenges. It also provides a comprehensive overview of the competitive landscape and strategies that impact the market growth.The Fr4 Multilayer PCB is a type of printed circuit board with multiple layers of copper foil, laminated together with an epoxy resin. This type of PCB is widely used in applications where high-density interconnects are required, including telecommunications, medical devices, consumer electronics, and automotive industry. The demand for Fr4 Multilayer PCB is expected to surge with the increasing adoption of advanced technologies and the growing need for compact and lightweight electronic devices.{Company Name} is a leading manufacturer of Fr4 Multilayer PCB, offering a wide range of products that cater to the diverse needs of the industry. Established in {year}, the company has built a strong reputation for its commitment to quality, innovation, and customer satisfaction. With state-of-the-art manufacturing facilities and a dedicated team of experts, {Company Name} has continuously raised the bar in delivering high-performance and reliable Fr4 Multilayer PCB solutions to its global clientele.The company takes pride in its ability to customize its products to meet the specific requirements of its customers. Whether it's a complex PCB design or a high-volume production, {Company Name} has the expertise and capabilities to deliver cost-effective and high-quality solutions. With a focus on research and development, the company stays ahead of the curve in developing cutting-edge PCB technologies that offer enhanced performance, durability, and reliability.The global Fr4 Multilayer PCB market is witnessing significant growth due to the rapid advancement in technology and increasing demand for smart and connected devices. The adoption of Fr4 Multilayer PCB is expected to escalate as industries continue to embrace automation, IoT, and artificial intelligence. The need for high-speed data transmission, miniaturization, and improved signal integrity are driving the demand for Fr4 Multilayer PCB in various applications.{Company Name} stands out as a leader in the Fr4 Multilayer PCB market, offering a comprehensive portfolio of products that meet the stringent quality standards and industry specifications. The company's commitment to sustainability and environmental responsibility is reflected in its manufacturing processes and product offerings. {Company Name} is dedicated to reducing its environmental footprint and promoting eco-friendly practices throughout its operations.The company's relentless pursuit of excellence has earned it a strong foothold in the global market, with a loyal customer base that spans across different industries and regions. As the demand for Fr4 Multilayer PCB continues to grow, {Company Name} is well-positioned to capitalize on the opportunities and strengthen its market presence. With a focus on customer satisfaction and continuous innovation, the company is poised for sustained growth and success in the years to come.In conclusion, the global Fr4 Multilayer PCB market is poised for remarkable growth, driven by the increasing demand for advanced electronic devices and technologies. {Company Name} emerges as a key player in the market, offering top-notch Fr4 Multilayer PCB solutions that address the evolving needs of the industry. With a strong focus on quality, innovation, and customer-centric approach, {Company Name} is set to make a significant impact in the Fr4 Multilayer PCB market and contribute to the advancement of electronic technologies.

Exploring the Advantages of Single Sided PCB Circuit Boards

In this fast-paced world of technological advancements, printed circuit boards or PCBs have firmly established themselves as one of the foundational building blocks of modern-day electronics. Efficiently serving as miniature pathways that connect different electronic components of a device, PCBs come in different types ranging from multi-layered to single-sided. Among these, single-sided PCBs have continued to gain increasing importance in the electronics industry, thanks to their affordability, high durability, and ease of use.In this vein, {Brand name removed} has recently announced the launch of their latest product: the single-sided PCB circuit board. As a company that prides itself in providing cutting-edge technological solutions to its clients, {Brand name removed} has added another feather to its cap. This single-sided PCB circuit board is engineered to operate with exceptional durability, making it an ideal choice for a variety of electronic device applications.{Brand name removed} has been providing best-in-class electronic circuit board solutions to its customers for several years and has already established itself as a go-to company for enterprises requiring high-quality PCBs for their electronic devices. Their new single-sided PCB circuit board is the latest addition to their already extensive line of circuit board solutions.Single-sided PCBs have been popular for a long time due to their affordable nature and versatility. They come with a single layer of conductive material, which is attached to an insulating substrate. It is then printed with a pattern of metallic traces that will connect the different components of an electronic device. They are designed to be thin and lightweight, making them easy to integrate into any electronic device. Their simple design means that they are cost-effective to produce, and this has made them a viable choice for several electronic device manufacturers.The new {Brand name removed} single-sided PCB circuit board is noteworthy due to its excellent performance metrics. Firstly, it has a higher mechanical stability compared to other single-sided PCBs. The stability in combination with the board's low weight makes it suitable for use in products that require optimal portability. Secondly, it features a high-temperature tolerance which is essential for devices that require high power in a small package. The high-temperature tolerance ensures that the PCB circuit board does not fail when there is an increase in temperature due to high power.{Brand name removed} has adopted a customer-centric approach, and that's why they have engineered their single-sided PCB circuit board using high-quality materials. The material used to build the boards is non-conductive, ensuring the board does not leak current at any point. The conductive layer applied to the board is of high quality, providing excellent connectivity between electronic components and ensuring the product is long-lasting.Another key feature of the {Brand name removed} single-sided PCB circuit board is its compact design. The small size and lightweight design of the board make it easy to integrate into any electronic device. Additionally, the board's sleek design means that it is highly customizable, providing device manufacturers with the flexibility to shape the PCB as per their requirements.Having an efficiently designed single-sided PCB circuit board means that devices do not need to take up too much space on the printed circuit board. Therefore, device manufacturers can build products with a smaller form factor, reducing the overall size and weight of the device. This reduction in size and weight provides customers with a product that is easy to transport and handle.{Brand name removed}'s latest product offering has high build quality and comes with tested durability, which is essential for electronic devices. Whether the product is meant for indoor or outdoor use, the {Brand name removed} single-sided PCB circuit board can withstand harsh environmental factors while maintaining optimal performance.In conclusion, {Brand name removed}'s new single-sided PCB circuit board is a remarkable product that can improve the overall performance of electronic devices. Its lightweight design, high-temperature tolerance, compact build and excellent connectivity make it perfect for a range of different products. As an expert in the manufacturing of electronic circuit components, {Brand name removed} ensures that its single-sided PCB circuit board is of the highest quality. This latest product offering will undoubtedly find wide acceptance among device manufacturers, making {Brand name removed} a preferred choice for electronic circuit boards.

Exploring the Benefits and Applications of Aluminum-Based PCBs

Title: Aluminum Base PCB Gaining Popularity: Innovations Paving the Way for Enhanced Electronic PerformanceIntroduction:In the ever-evolving electronics industry, the demand for high-performance printed circuit boards (PCBs) has significantly increased. One such innovation making waves is the Aluminum Base PCB, designed to provide exceptional heat dissipation capabilities. This article highlights the growing popularity of Aluminum Base PCBs and delves into the key features that make them stand out from conventional PCBs.Paragraph 1:Aluminum Base PCBs have witnessed a surge in utilization across various industries due to their unmatched thermal management properties. They offer exceptional heat dissipation, making them ideal for high-power applications where temperature control is critical. The combination of high thermal conductivity of aluminum and the multilayer construct of the PCB allows for efficient heat transfer, leading to increased performance and reliability.Paragraph 2:The advantages of Aluminum Base PCBs extend beyond thermal management; they also offer enhanced mechanical strength and rigidity. The aluminum substrate provides stability to the overall structure, preventing warping and ensuring longevity, even in demanding operating conditions. These attributes make Aluminum Base PCBs a popular choice in sectors such as automotive, aerospace, LED lighting, and power electronics.Paragraph 3:One of the most significant advantages of Aluminum Base PCBs is their compatibility with Surface Mount Technology (SMT), which greatly simplifies the assembly process. The aluminum substrate serves as an excellent thermal conductor during soldering, facilitating quick and efficient temperature transfer, leading to improved solder joint formation. This compatibility enhances productivity, shortens production lead times, and reduces costs in manufacturing processes.Paragraph 4:Several companies have been at the forefront of Aluminum Base PCB innovation, catering to the growing market demand. While each company brings its unique expertise and technologies, one company that has stood out is {}. Recognized for its commitment to excellence, their Aluminum Base PCBs have made a significant impact across multiple industries. By combining the most advanced engineering techniques with top-notch materials, their PCBs deliver unmatched performance and reliability.Paragraph 5:As the demand for high-performance electronic devices continues to grow, the aluminum base PCB market is projected to witness significant expansion. The automotive industry, in particular, is one of the key sectors driving this growth. Due to the increasing electrification of vehicles, the need for efficient thermal management systems in electric and hybrid vehicles has become paramount. Aluminum Base PCBs offer a reliable solution, ensuring the optimal functioning of sensitive electronic components.Paragraph 6:Beyond automotive, industries such as telecommunications, renewable energy, and industrial automation are also increasingly adopting Aluminum Base PCB technology. From power converters and motor controls to communication infrastructure and solar inverters, the unique attributes of Aluminum Base PCBs ensure stable performance, longevity, and efficient heat dissipation.Conclusion:With their exceptional thermal management properties, mechanical strength, and compatibility with modern manufacturing processes, Aluminum Base PCBs have emerged as a game-changer in the electronics industry. The relentless pursuit of innovation and commitment to delivering superior quality by companies like {} have laid the foundation for enhanced electronic performance. As the demand for high-power applications and thermal management efficiency grows, Aluminum Base PCBs are set to revolutionize the industry, driving technological advancements and powering the devices of tomorrow.

Ultimate Guide to Programmable Circuit Boards: What You Need to Know

Innovative Programmable Circuit Board Revolutionizing Electronics IndustrySeptember 28, 2023The electronics industry is witnessing a remarkable transformation with the introduction of a cutting-edge Programmable Circuit Board (PCB). This revolutionary technology, developed by a leading electronics company, is poised to reshape the way electronic devices are designed and manufactured.The Programmable Circuit Board, developed by the {company name}, is a state-of-the-art electronic component that offers unprecedented flexibility and customization options for a wide range of applications. Unlike traditional circuit boards, which are static and fixed in their functionality, the Programmable Circuit Board can be reconfigured and reprogrammed on the fly, allowing for rapid prototyping and iteration of electronic designs.One of the key features of the Programmable Circuit Board is its modular design, which enables engineers and designers to easily customize the functionality of the board to meet the specific requirements of their applications. This level of flexibility is unprecedented in the industry and is expected to have a profound impact on the development of new electronic devices.The {company name} is a renowned leader in the electronics industry, with a long history of innovation and excellence in electronic component manufacturing. The company's commitment to pushing the boundaries of what is possible in electronics design and manufacturing has led to the development of the Programmable Circuit Board, which is set to become a game-changer in the industry.The introduction of the Programmable Circuit Board is expected to have far-reaching implications for a wide range of industries, including consumer electronics, automotive, aerospace, medical devices, and more. With the ability to rapidly prototype and iterate electronic designs, engineers and designers will be able to bring new products to market faster and more efficiently than ever before.In addition to its modular design and reconfigurable functionality, the Programmable Circuit Board also offers advanced features such as integrated sensors, wireless communication capabilities, and power management, making it a truly versatile platform for a wide variety of applications.The {company name} has already begun working with leading electronics manufacturers to integrate the Programmable Circuit Board into their product designs, and the early results have been nothing short of impressive. By leveraging the flexibility and customization options of the Programmable Circuit Board, these manufacturers are able to develop new electronic devices that were previously not possible with traditional circuit board technology.Furthermore, the Programmable Circuit Board has the potential to greatly reduce the environmental impact of electronic device manufacturing. By enabling more efficient design iterations and reducing the need for multiple prototypes, the Programmable Circuit Board can help to minimize waste and energy consumption in the electronics industry.With the introduction of the Programmable Circuit Board, the {company name} is once again demonstrating its commitment to driving innovation and pushing the boundaries of what is possible in electronics design and manufacturing. The company's groundbreaking technology is poised to revolutionize the industry and unlock new possibilities for electronic device development.As the electronics industry continues to evolve, the Programmable Circuit Board is expected to play a pivotal role in shaping the future of electronic devices and revolutionizing the way we interact with technology. The {company name} is proud to be at the forefront of this transformation, and is excited to continue pushing the boundaries of what is possible in electronics design and manufacturing.

Industry-Leading PCBA Assembly Manufacturer Offers Top-Notch Services for Electronic Assembly Projects

As technology advances, many companies are looking for ways to improve their production processes, efficiency and quality. One key area where this is evident is in the manufacture of Printed Circuit Board Assemblies (PCBAs). The assembly of PCBAs is a highly specialized process that requires a high degree of precision and advanced technological know-how. This is why many companies are turning to reputable PCBA assembly manufacturers for help.One such manufacturer, which we shall refer to as “Company A,” has been at the forefront of providing high-quality PCBA assembly services to clients in various industries for many years. The company prides itself on its wealth of expertise and experience in electronics manufacturing, and its commitment to quality, reliability, and precision in all its services.Company A offers a wide range of services in the PCBA assembly process, from design prototyping and testing, to component procurement, assembly, and packaging. They have an efficient system that allows them to assemble both Surface Mount Technology (SMT) and Through-Hole Technology (THT) components, which are essential in the manufacturing of PCBAs.In addition, the company also uses advanced technological tools such as Automated Optical Inspection (AOI), which enables them to inspect PCBAs for any faults or defects. This ensures that their clients receive fully functional and error-free PCBAs, which are vital to their businesses. It's worth noting that the company's rigorous quality control process ensures they rarely experience any faulty products, which saves clients time and reduces overall production costs.One key reason why Company A is highly reputable is because they are transparent and maintain an open line of communication with clients. They work closely with their clients and provide regular updates on the progress of their projects. This is crucial in ensuring that clients get exactly what they need and when they need it. Their customer service is available throughout the PCBA assembly process, helping clients stay informed and up-to-date with the status of their projects.Another factor that sets Company A apart from its competitors is its commitment to providing eco-friendly manufacturing solutions. The company adheres to strict environmental regulations and policies in production, and this has enabled them to achieve the ISO14001 environmental management certification. This shows the company's dedication to sustainability and reducing their carbon footprint.Company A has also invested in training their employees on the latest technologies and manufacturing practices in the PCBA assembly process. This has enabled them to provide cost-effective and innovative solutions to clients, while still maintaining high quality and timely delivery.In conclusion, Company A has established itself as a leading PCBA assembly manufacturer in the electronics industry. They consistently deliver high-quality PCBA assembly services to clients across different sectors, while prioritizing efficiency, transparency, and eco-friendliness. As technology continues to evolve, it's evident that this company is committed to providing cutting-edge solutions that meet their clients' needs and surpass their expectations.